B3S Linear Actuators

B3S ball screw linear actuators have an enclosed ball bearing design that accomodates heavy loads, high bending moments and delivers long service life.

The B3S ball screw linear actuator is capable of accommodating heavy loads and handling high bending moments with consistent, smooth operation. B3S ball screw actuators incorporate an enclosed recirculating ball bearing system that eliminates the need for external load guidance. The B3S ball screw linear actuator delivers repeatability and 100% duty cycle with long service life.

- 3 body sizes

- Ball or acme screw choices

- Load carrying capacities up to 8032 lbf (35.7 kN)

- Strokes up to 179 inches (4,547mm) depending on screw selections

- US customary (standard) and metric (optional) construction

- Mount your motor of choice with Tolomatic’s Your Motor Here® program

Features & Ordering

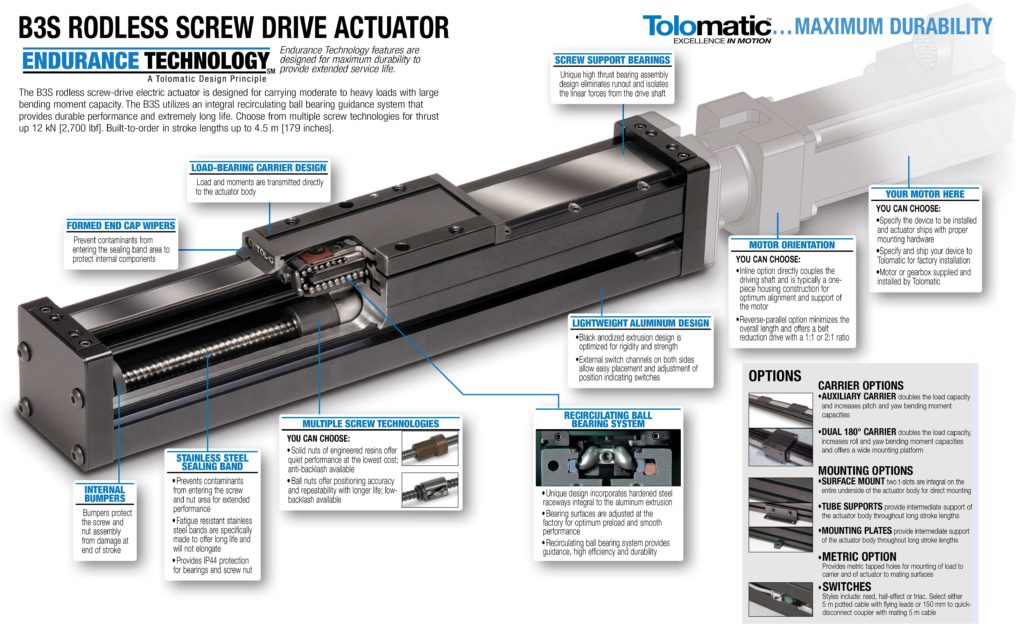

Download the B3S Brochure for full details on features

B3S Features

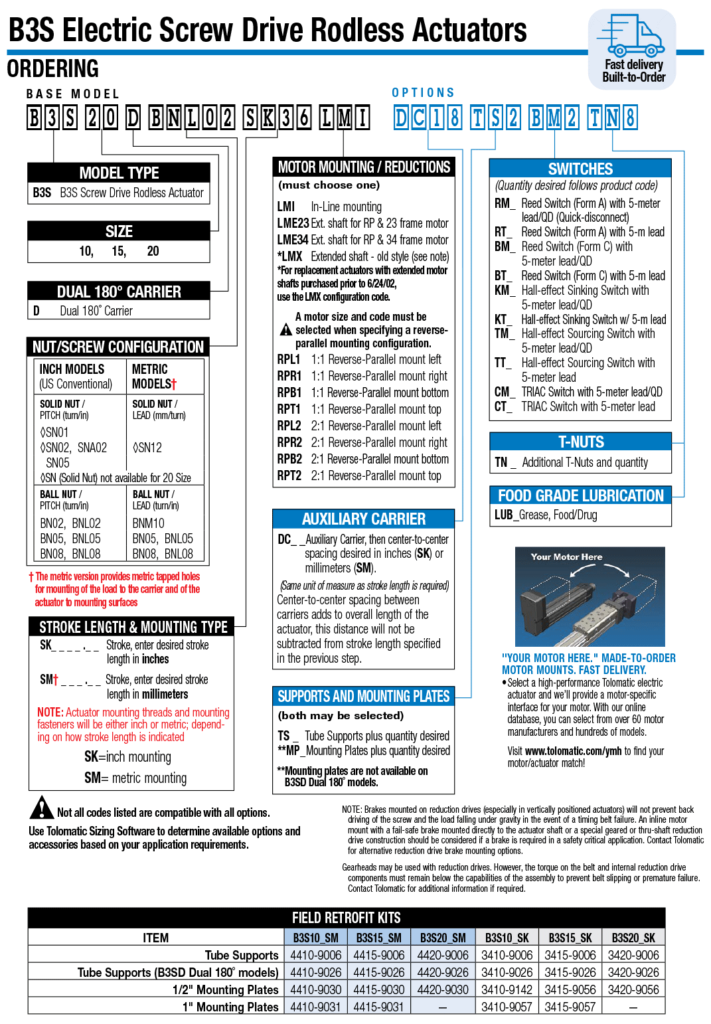

B3S Ordering

Specifications

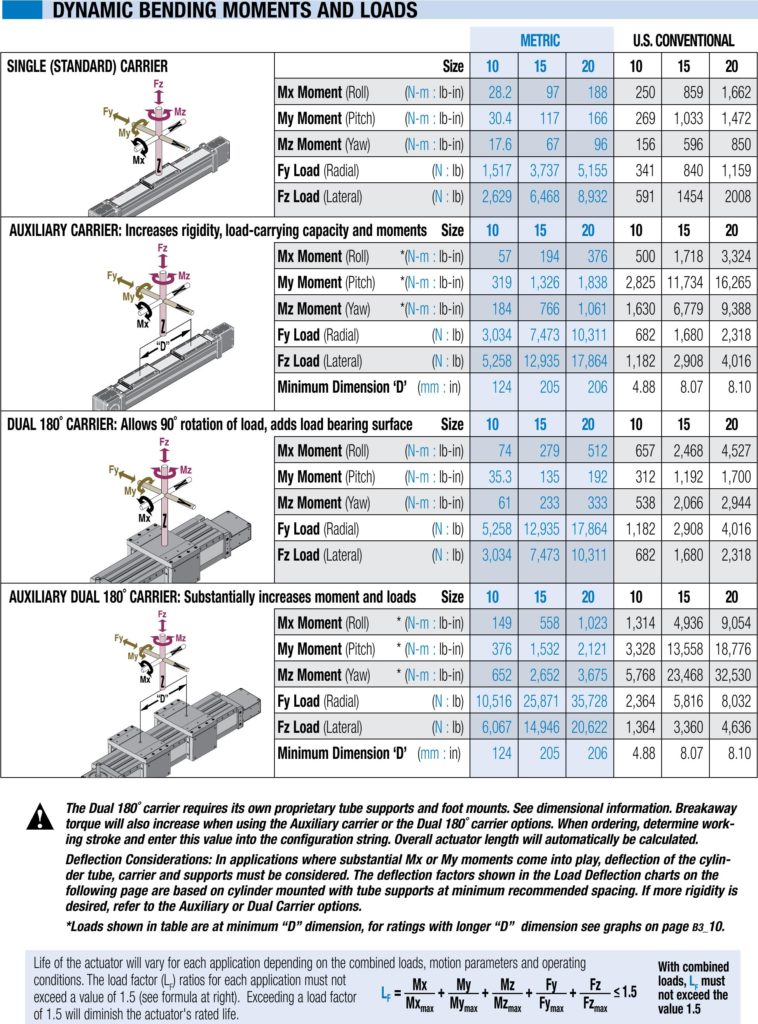

| Specifications | Units | B3S10 | B3S15 | B3S20 |

|---|---|---|---|---|

| Maximum Stroke | in (mm) | 136 (3,454) | 133 (3,378) | 131 (3,337) |

| Maximum Force | lbf (N) | 170 (756) | 800 (3,559) | 2,700 (12,010) |

| Maximum Load | lbs (kg) | 591 (268) | 1,454 (660) | 2,008 (911) |

| Maximum Speed | in/sec (mm/sec) | 60 (1,524) | 60 (1,524) | 60 (1,524) |

B3S Screw Drive Specifications

Dimensions

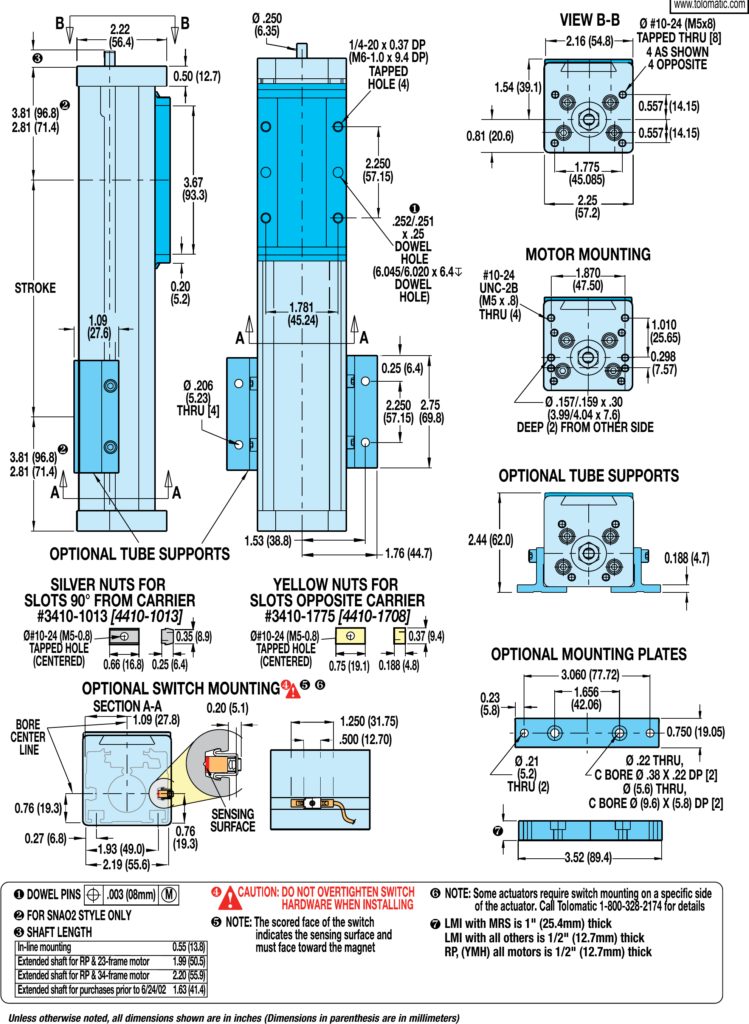

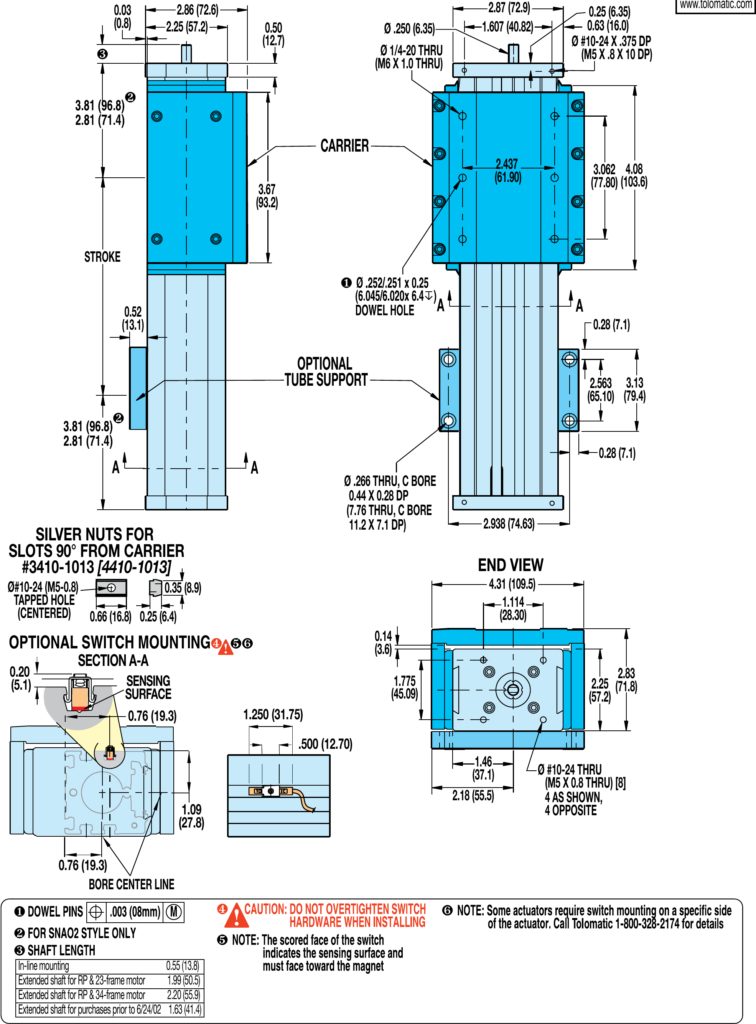

B3S10 Actuator & Options Dimensions

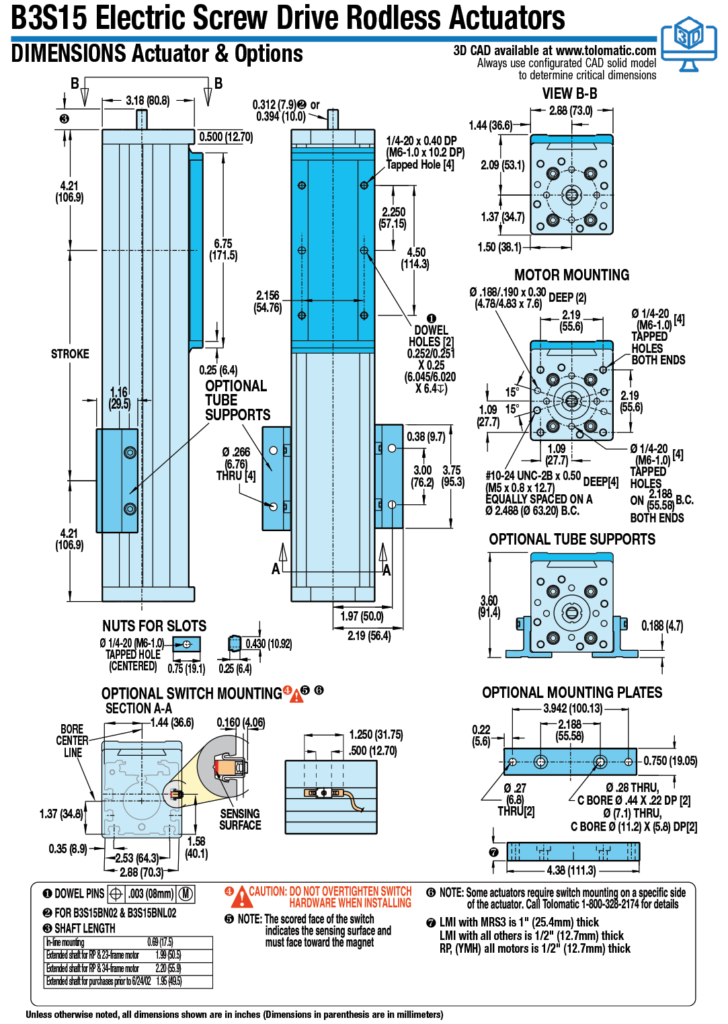

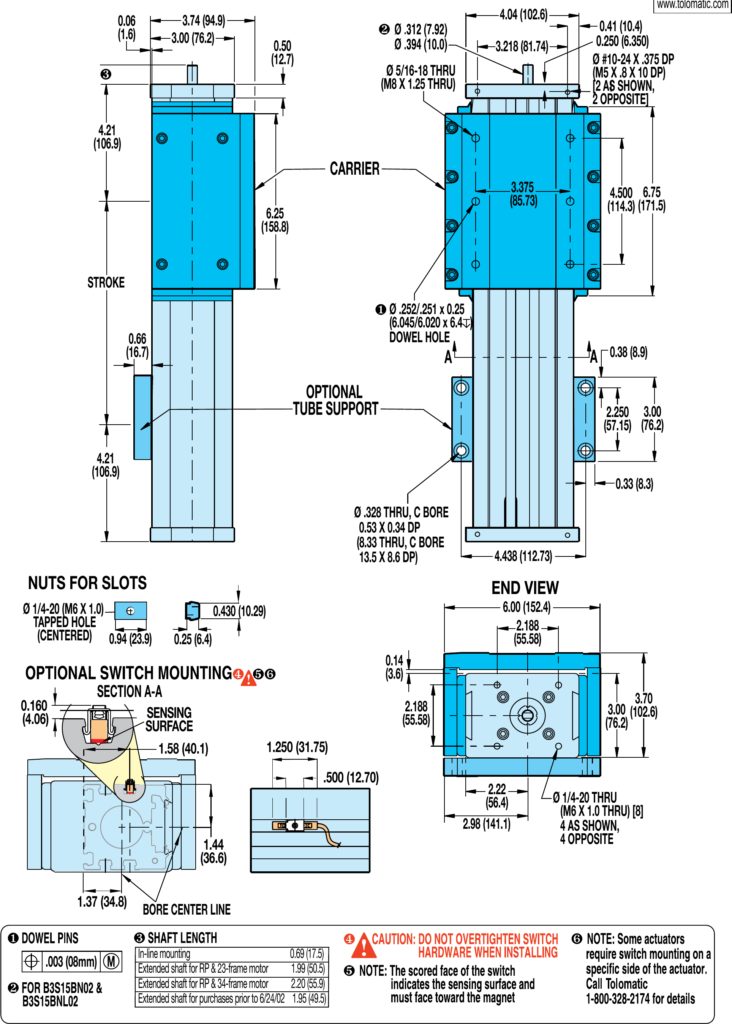

B3S15 Actuator & Options Dimensions

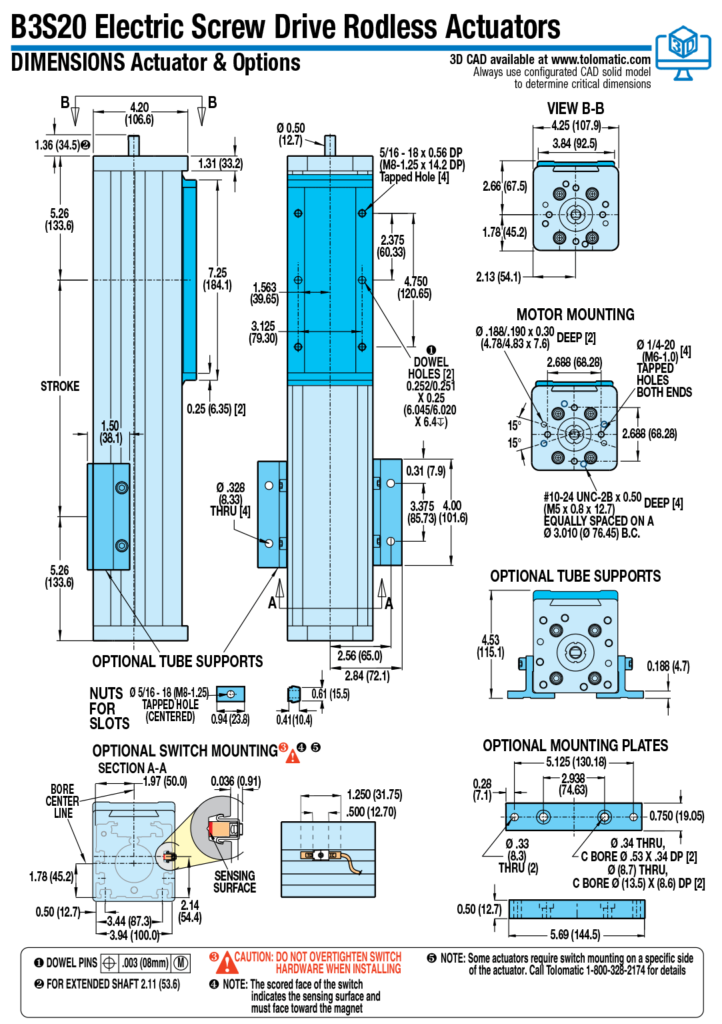

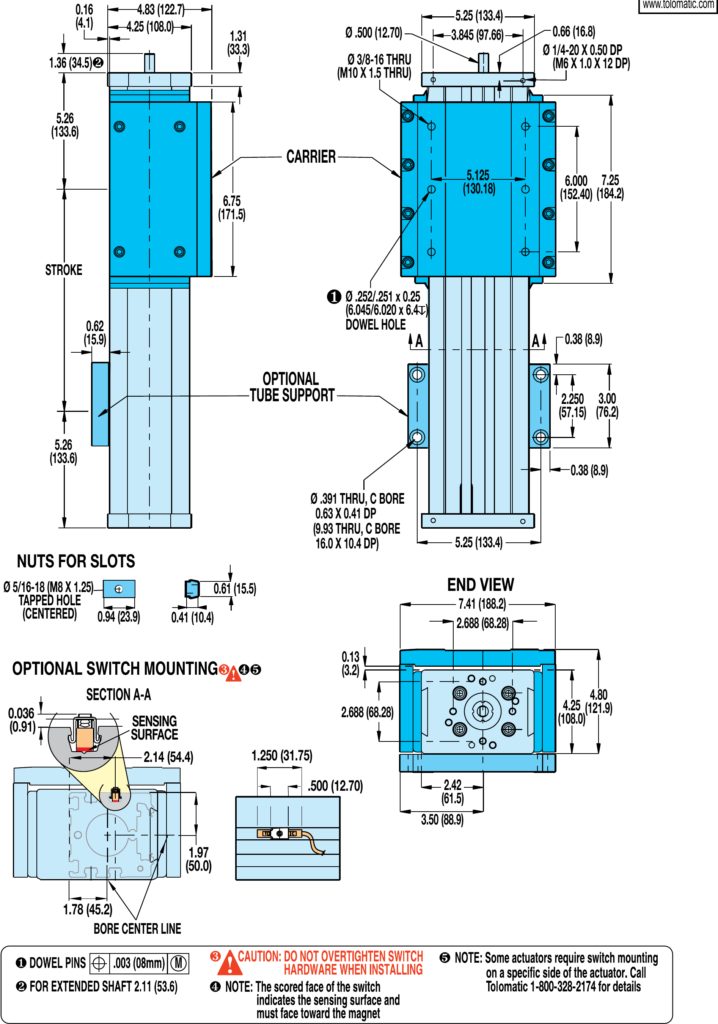

B3S20 Actuator & Options Dimensions

B3S10 Dual 180º Option Dimensions

B3S15 Dual 180º Option Dimensions

B3S20 Dual 180º Option Dimensions

Get CAD

Manuals & Part Sheets

Additional Resources

Information Center:

English

Chinese

German

Spanish

Application Checklists

Case Studies

Catalogs & Brochures

- Corporate Overview-Linear Motion Solutions Brochure (English)

- SOLUCIONES DE CONTROL DE MOVIMIENTO (Spanish, Corporate Overview-Motion Control Solutions Brochure)

- Unternehmensübersicht (German, Corporate Overview brochure)

- Brochure sur l'entreprise Tolomatic (French, Corporate Overview-Linear Motion Solutions Brochure)

- B3S/B3W Electric Rodless Actuators Catalog

- Aplicaciounes de la Ind. Automotriz (Auto Appl SP)

- Gantry & Multi-Axis Solutions Brochure

- Soluciones Gantry y Multieje (^ES Gantry brochure)

- Medical and Life Sciences brochure

- OEM Actuator Solutions Brochure

Guides

- Selecting the Optimal Screw Technology

- Actuator Life: How to estimate for ball and roller screw actuators

- INFOGRAPHIC: Accuracy and Repeatability in Linear Actuators

- INFOGRAPHIC: Ten Tips for Specifying Rodless Electric Linear Actuators

- INFOGRAPHIC: Calculating Total Cost of Ownership

- 如何选择 螺杆? 甄选 正确的技术 (Chinese, How to select the right lead screw for an electric actuator)

- Abschnitt: Welches Gewinde? Die richtige Technologie auswählen (German - Which Screw)

- Guide to Third Party Motor Integration

- Switch Reference Guide

Tech Bulletins

Terms & Conditions

White Papers

- Electric actuators vs. pneumatic cylinders: A comparison based on total cost of ownership

- The truth about actuator life: Screw drive survival

- Select the right linear actuator: Making sense of manufacturer specifications

- Specifying electric rodless actuators: Ten tips for maximizing actuator life and system performance

- Rules of actuator and guide alignment in linear motion systems

- IP ratings and the manufacturing environment: How to apply linear actuators for quality, safety and long service life.

- Minimizing electrical noise in actuator drive systems for maximum reliability and performance

- Screw-driven vs. belt-driven rodless actuators: How to select drive trains for reliability, efficiency and long service life

- Introduction to accuracy and repeatability in linear motion systems

- Elektrische Stangenantriebe vs. Hydraulikzylinder: Ein Vergleich der Vor- und Nachteile beider Technologien weißes Papier (Electric vs Hydraulic WP, German)

- Designing Gantry and Multi-Axis Automation Systems