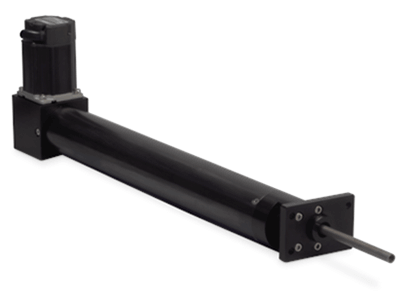

Custom Designed and Built Linear Actuators

At Tolomatic, we welcome the opportunity to create custom linear actuators for our customers: electric or pneumatic actuators, caliper brakes, gearboxes and other motion control devices. Think of custom actuator design as starting with a blank page. The ability to tackle custom work requires a strong design engineering department capable of turning your pains into real solutions run by a group of people who are willing to think outside the box.

We have our own in-house modeling and testing capabilities where custom actuators can be easily altered and controlled to fit the needs of the final design. The skilled technicians in our model shop control the complete process from beginning to end to ensure quick, efficient prototyping that conforms to the highest quality standards. The skilled technicians in our model shop control the complete process from beginning to end to ensure quick, efficient prototyping that conforms to the highest quality standards.

What are the benefits of custom actuator product designs?

Custom linear electric actuator designs provide specialized solutions that enhance efficiency and functionality for unique applications. By tailoring specifications, these actuators can significantly improve system performance.

- Optimized Performance: Custom designs can be fine-tuned for specific load capacities and motion requirements.

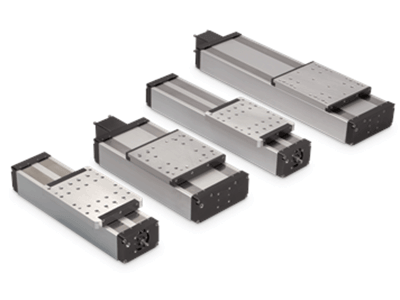

- Space Optimization: Actuators can be designed in various sizes and configurations to fit limited spaces.

- Improved Durability: Custom solutions can be engineered to withstand specific environmental conditions, enhancing reliability.

- Cost Efficiency: Tailoring designs can minimize material waste and lower overall manufacturing costs, leading to better long-term value.

How does the custom actuator design process work?

Here’s what to expect when you come to Tolomatic for a custom-built solution:

- Requirements Consultation: First you’ll collaborate with our design engineers for preliminary evaluation and concept analysis.

- Preliminary Design: Next we combine your needs with our expertise to develop an initial product design.

- Rapid Prototype: You’ll receive a prototype product for initial evaluation of form, fit, and function.

- Design Verification and Acceptance: Testing occurs to verify performance to your specifications.

- Production: Once we have final approval, your customized product will be produced and delivered.

Start the Design Process

with Our Experts

Interested in examples of our custom designed actuators?

Low-profile Precision Stage

ServoChoke® SVC Electric Choke Valve Actuator / Operator

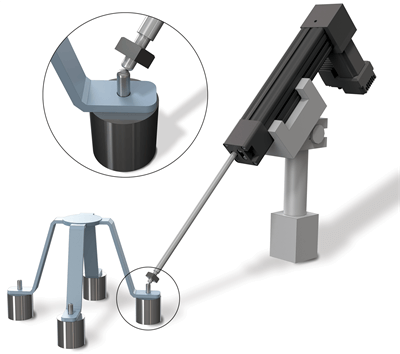

ServoPlace™ Precision Nut Placement

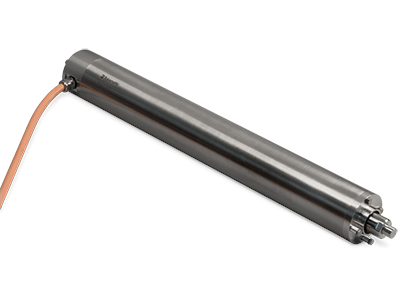

Stainless-steel Electric Actuator

Stainless-steel Integrated Actuator

Stainless-steel Servo Motor