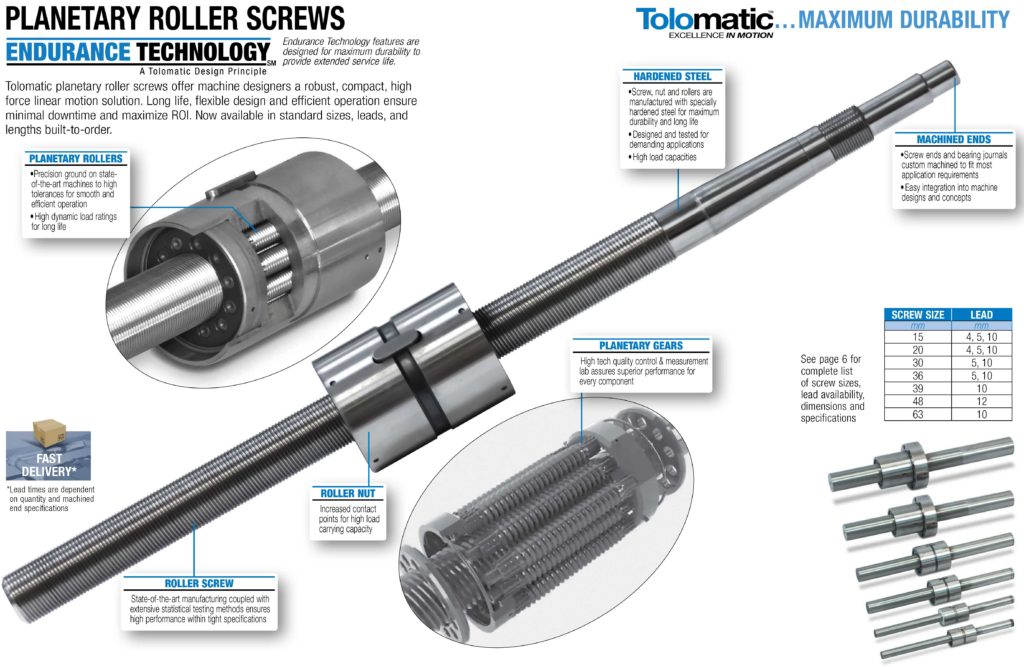

Planetary Roller Screws

High Force and Efficient Operation in a

Compact Package

Roller screws—also called planetary roller screws—have precision-ground screw threads that match multiple precision-ground rollers in the nut. These rolling elements provide more points of contact, allowing for higher force capability and longer life. Tolomatic roller screws set themselves apart by having a very deep case (surface) hardness and a high Dynamic Load Rating (DLR*).

Tolomatic manufactures thousands of roller screws per year for applications around the world.

How do we ensure top-tier performance for our roller screws?

Tolomatic’s planetary roller screws are manufactured in the United States using state-of-the-art equipment to maintain strict tolerances and the highest quality standards.

- Configurable stroke lengths

- Industry best lead times

- Extensive quality testing and verification completed in-house

- Extended lifetime, no matter how demanding the location or application

- Appropriate for smaller, lightweight designs and machine concepts

Roller Screw Overview

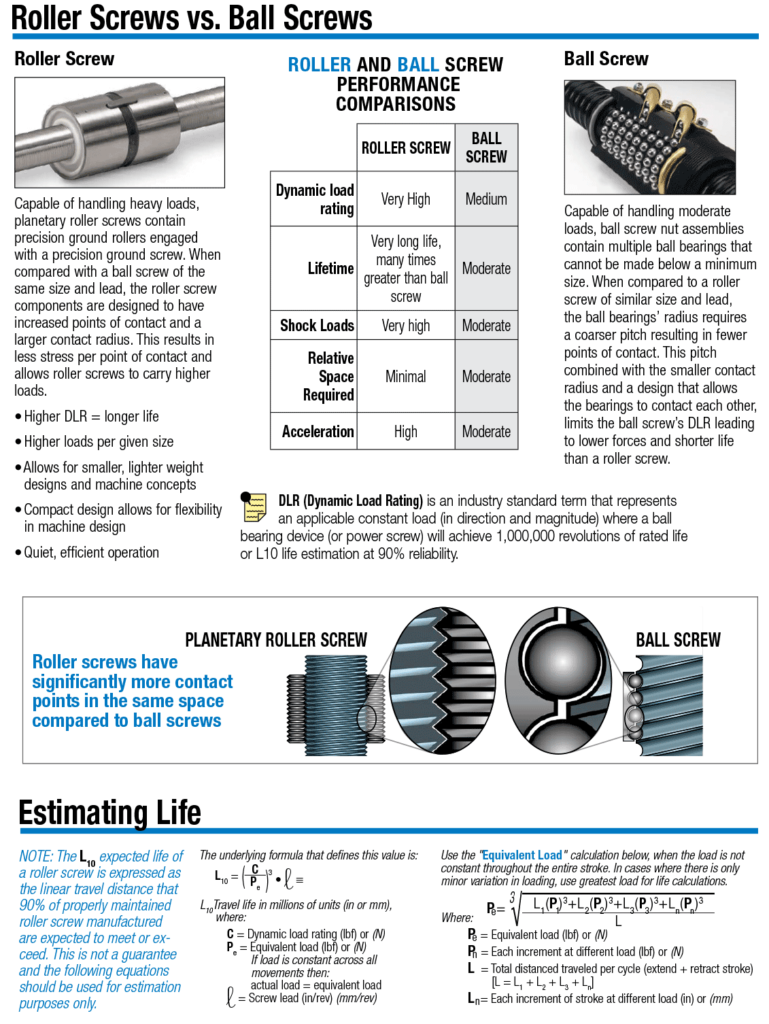

Roller Screw vs. Ball Screws/ Estimating Life

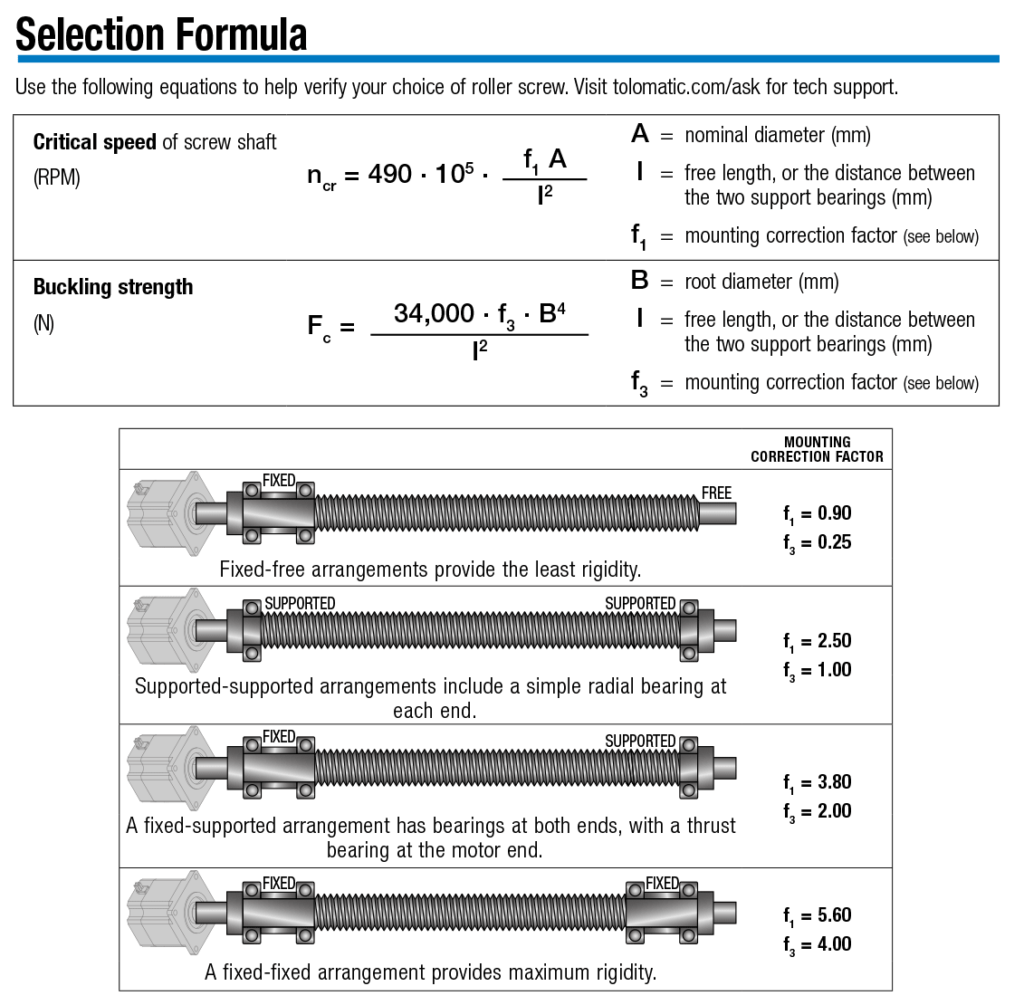

Roller Screw Selection Formula

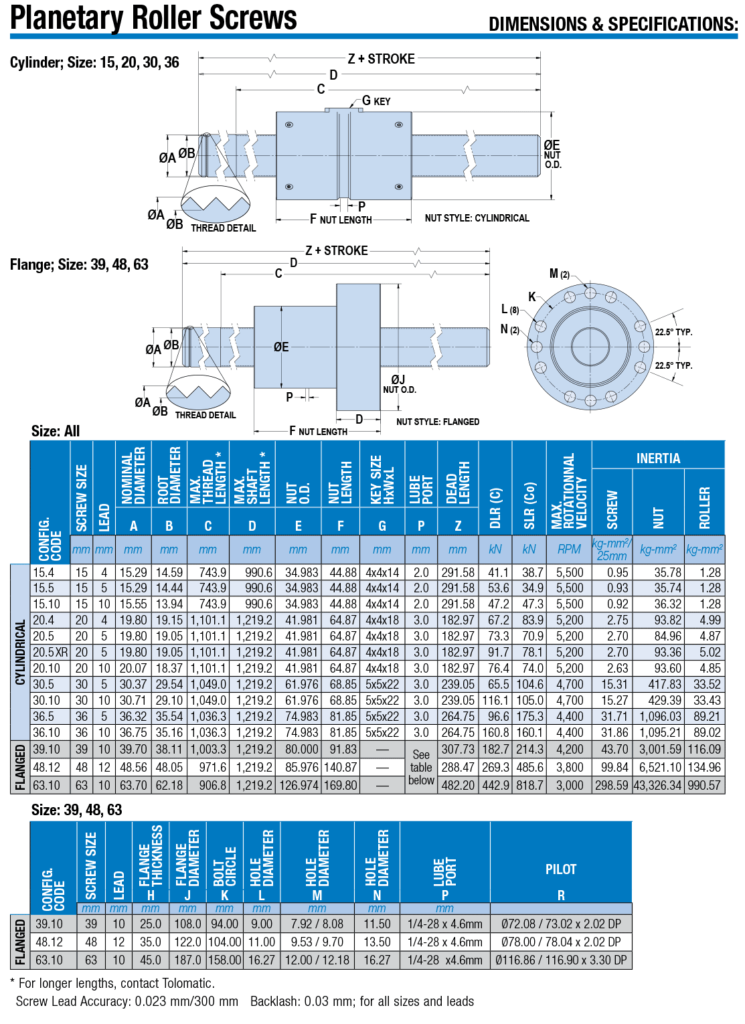

Roller Screw Dimensions & Specifications

Information Center:

English

Chinese

German

Spanish

Catalogs & Brochures

Guides

Terms & Conditions

Videos

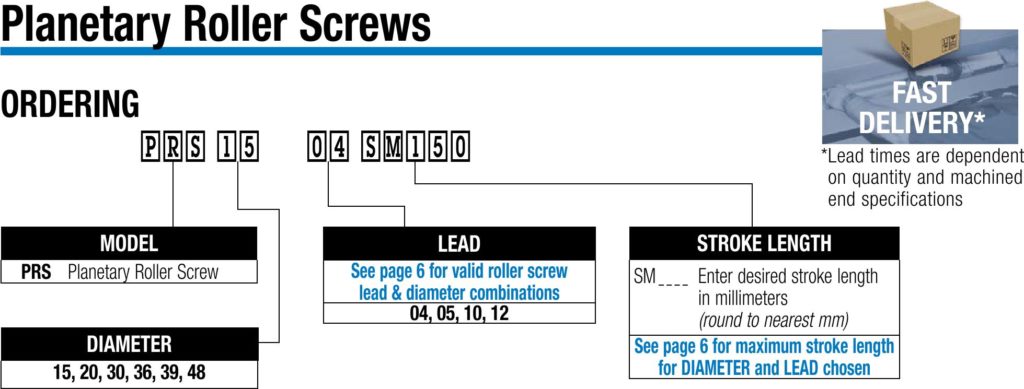

Roller Screw Ordering

Ask an Engineer

Ask an Engineer