Rod Style Roller Screw Actuator Comparison

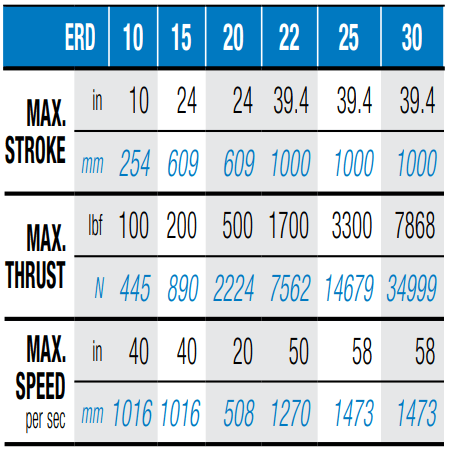

ERD HYGIENIC ROD-STYLE ACTUATOR |

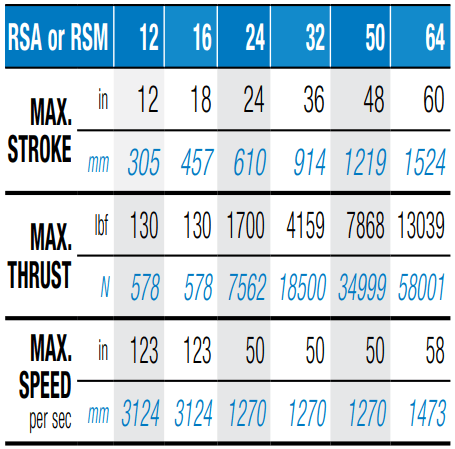

RSA ROD-STYLE ACTUATOR |

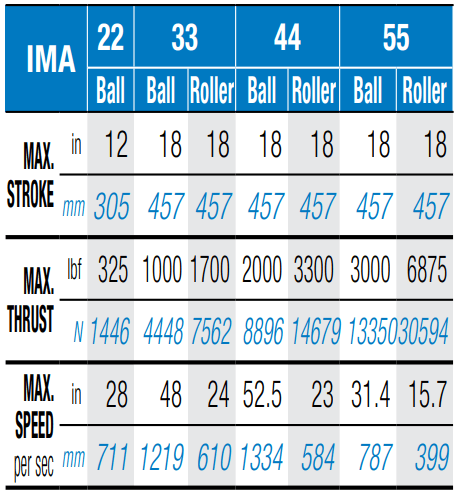

IMA INTEGRATED MOTOR/ACTUATOR |

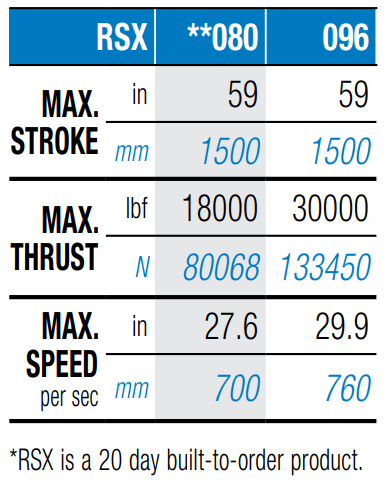

RSX ROD-STYLE ACTUATOR* |

|

|

|

|

APPLICATIONS: |

APPLICATIONS: |

APPLICATIONS: |

APPLICATIONS: |

|

|

|

|

FEATURES: |

FEATURES: |

FEATURES: |

FEATURES: |

|

|

|

|

OPTIONS: |

OPTIONS: |

OPTIONS: |

OPTIONS: |

|

|

|

|

SPECIFICATIONS: |

SPECIFICATIONS: |

SPECIFICATIONS: |

SPECIFICATIONS: |

|

|

|

|

WIDE RANGE OF CAPABILITIES • CONFIGURABLE STROKES • CLEAN LEAK-FREE PERFORMANCE • FAST DELIVERY

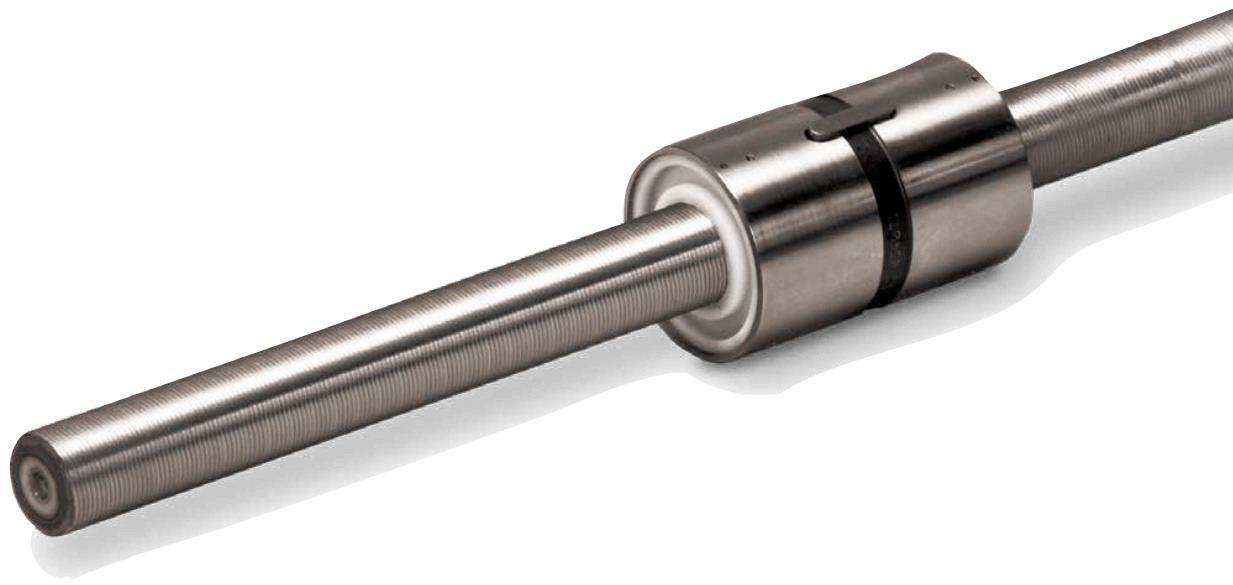

Planetary (standard) roller screw linear actuators

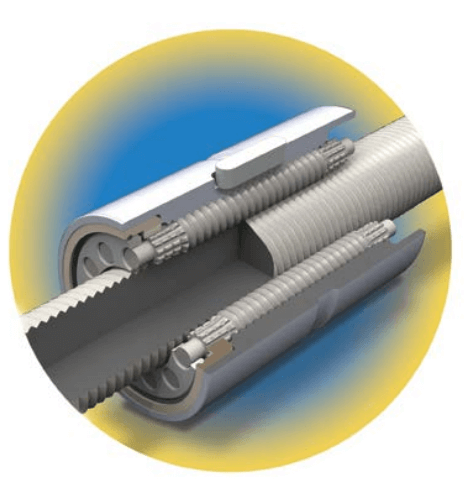

Roller screws (also called planetary roller screws) have triangular-shaped, precision-ground threads that match multiple precision-ground threaded rollers in the nut. These rolling elements transmit force very effectively. Roller screw components are designed with a fine pitch, providing more points of contact and a larger contact radius. The result is less stress per point of contact.

Roller screws have very high force transmission capabilities since the rollers have significant contact with the screw threads. They can deliver high force, operate at high speeds, are long-lasting and require little maintenance. The use of planetary roller screws is allowing engineers to specify electric actuators in applications that were once the sole province of hydraulic cylinders.

An inverted roller screw operates much the same as a standard roller screw except the functions of the nut and screw are reversed. The rollers move inside the nut.

Most inverted roller screws used in linear actuators are produced using a process other than grinding to inexpensively create threads inside the nut. The hardening process is performed after the nut is machined and results in a much shallower case hardness depth and softer threads than those of standard roller screws. This leads to a significantly lower DLR* (lower life) and more challenges with maintaining lubrication.

Tolomatic manufactures standard roller screws for use in their electric actuators. These screws are case (surface) hardened before precision grinding, resulting in very deep case hardness and high Dynamic Load Rating (DLR*).

*What is dynamic load rating? DLR is an industry standard term that represents an applicable constant load (in direction and magnitude) where a ball bearing device (or power screw) will achieve 1,000,000 revolutions of rated life or L10 life estimation at 90% reliability. DLR is usually provided by the manufacturer.

Ask an Engineer

Ask an Engineer