Screw-driven vs. belt-driven rodless actuators: How to select drive trains for reliability, efficiency and long service life

Introduction

Most electromechanical rodless actuators commonly use one of two main drive trains to convert rotary motion of the electrical motor to linear motion of the actuator’s load-carrying device: a power screw drive or a timing belt drive. While both screw and timing belt drives offer efficiency, reliability and long life while requiring very little maintenance, each has its limitations. This paper describes how each drive train works, what materials are used and why each is suited for a particular application. Drive trains are integral to actuator design; understanding their critical aspects and parameters is an important first step to creating efficient and economical motion control systems.

KEY FACTORS AFFECTING DRIVE TRAIN SELECTION

Power screw drives and timing belts carry a dual function in linear motion. They are used for linear positioning and therefore need to provide acceptable accuracy and repeatability. At the same time they transmit power, which requires them to possess sufficient strength. A screw mechanism produces linear motion by rotating either (most common) the screw or the nut in an assembly. Similarly, timing belt drives transmit torque and linear motion from a driving pulley via the belt to a driven pulley.

The motion control application determines which drive train to select. Basic to any motion control system selection are duty cycle, life cycle and cost. More pertinent to drive train selection are length of stroke, linear velocity and acceleration, as well as orientation of move. Drive trains vary in capacity, so thrust of the actuator, as well as load and force of the actuator carrier, will also affect drive train choice. Shock loads and noise are important considerations for some types of processing.

Additional factors that determine the selection of drive train technology include:

- Accuracy of a positional move (the ability of the actuator to achieve a commanded position, or the difference between the actual position and a commanded one)

- Repeatability (the degree to which an actuator can return to a reference position in multiple attempts. Unidirectional repeatability is measured by approaching the position from a single direction; bidirectional repeatability is measured by approaching it from opposing directions)

- Permissibility of backdriving (ability of an electromechanical actuator to lose its carrier’s position under axial load at loss of power)

POWER SCREW DRIVES: High axial thrust, moderate stroke length and speed

Power screw drives are known for high-thrust capacity as well as accuracy and repeatability. Relatively low system inertia and predictable service life (ball and roller screw drives) are additional benefits. These parameters make power screw drives ideal for a variety of applications such as machine tools, assembly and packaging equipment, robots etc.

The limitations of power screw drives include shorter length than belt drives, running speeds limited by critical speed values (rotational speeds approaching the system’s natural vibration frequency, leading to resonance), and reduced duty cycle compared to belt drives.

Three primary types of screws are used in linear actuators: lead (or Acme), ball screws and, less common, roller screws. The differences are in the design of the thread shape along with the design and operation of a matching nut.

1. Lead Screws

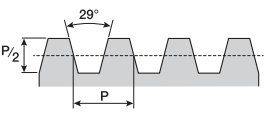

Lead screws (also called Acme screws) are known for their relatively low cost and smooth, quiet operation. The trapezoidal threads of lead screws are made of carbon, alloy or stainless steel (typically produced by rolling in lengths up to 12 feet), and are available in a wide variety of diameters and leads. Solid nuts used with lead screws are usually made of composite materials (most commonly acetal resins) or bronze.

Fig. 1. Trapezoidal thread of an Acme screw

A solid nut sliding along a lead screw’s threads creates a line contact between the surfaces of the two parts. As a result of the friction losses of this motion, drive efficiency is less than 60 percent. Drive efficiency is a function of (a) coefficients of friction between lead screw and lead nut; and (b) the lead screw’s helix angle.

Energy lost due to friction is dissipated as heat, which limits the application’s duty cycle. Heat generation prevents actuators driven by lead screws from being used at high speeds (aside from critical speed limitations) or with high axial loads.

Bidirectional repeatability is mainly affected by the amount of axial backlash or free play of a lead nut on the screw. Unidirectional repeatability is typically affected by component wear. Typical rolled-lead nuts will produce up to .010” (.254 mm) of backlash. In many cases, anti-backlash, spring-loaded, self-adjustable lead nuts (available in a variety of designs) eliminate this problem.

Due to low efficiency, most lead screws (all those with efficiency under 50 percent) cannot be backdriven.

2. Ball Screws

Ball screws are power screws that work as helical raceways for high-grade, chrome steel ball bearings. Ball recirculate inside a nut and are normally manufactured of high-carbon, alloy or hardenable stainless steel. Depending on lead accuracy requirements, ball screws can be produced by rolling in lengths up to 12 feet, or precision-grinding in shorter lengths. They are also available in a variety of diameters and leads. Ball screws with ground threads cost significantly more than rolled screws, but can be manufactured with a high lead accuracy grade that some applications require.

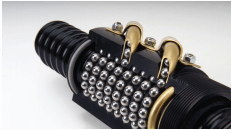

Fig. 2. A ball nut with two circuits of balls.

(Photo courtesy of Rockford Ball Screw)

Ball-screw assemblies offer two main advantages compared to lead screws: Balls move along the screw threads in a rolling motion based on a point of contact between the surfaces. This significantly reduces friction and increases mechanical efficiency (which for most ball screw drives is typically no less than 90 percent).

- Since ball nuts are essentially rolling bearings, their dynamic load ratings can be readily calculated according to ISO standards. This makes expected service life highly predictable. 2

- As with lead nuts, different methods control backlash and improve repeatability of ball nut assemblies. Spring-loaded ball nuts are available, as well as ball nuts that are custom fit with balls of selected sizes that minimize backlash or eliminate it altogether, effectively creating negative clearance or preload.

Due to their high efficiency, properly lubricated ball screw drives offer higher speeds (limited by critical speed values as well as by allowable speeds of ball recirculation inside a nut) and higher duty cycles compared to lead screws. Ball nut assemblies are capable of delivering a high thrust. Available thrust is a function of the size and total number of the balls in a ball nut assembly. Because of their high efficiency, most ball nuts can be backdriven.

While offering a smooth linear motion, ball screw drives are often noisier than lead screw drives.

3. Roller Screws

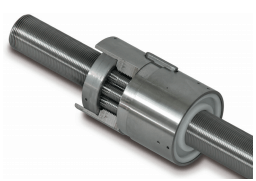

Roller screw drives are not commonly used in rodless actuator applications. Information is given here primarily for reference purposes. Rodless actuators typically have a built-in bearing system, and as a result are designed to “carry” loads as opposed to “pushing” them. Due to this fact, thrust requirements are usually much lower. In most rodless applications, ball screw drives are quite capable of handling the force and precision and don’t require the higher thrust capacities or the higher cost of roller screw drives. Planetary roller screws use threaded rollers, instead of balls, as the load transfer elements between nut and screw. Providing more bearing points than ball screws within a given volume, roller screws can be more compact for a given load capacity. They are made of alloy steel and are manufactured by grinding—which accounts for their higher cost.

Fig. 3. A typical planetary roller nut

Roller screws have significantly higher service life than ball screws. Roller screw actuators have high dynamic load ratings (up to several dozen tons of force). Only hydraulic cylinders have higher single-unit actuator capacity. Roller nuts have lower efficiency than ball nuts and are prone to overheating in high duty-cycle applications. Roller nuts, however, are invaluable from the standpoint of “force density” and life.

TIMING BELT DRIVES

The teeth of a timing belt mesh with corresponding grooves on the pulleys, preventing any relative motion between the belt and pulleys. This ensures synchronous linear motion with a permanent speed ratio.

Timing belt drives are efficient (90 percent to 93 percent) and easy to operate and maintain. They have a long service life because there are few moving parts and low component wear. They can be operated at 100 percent of duty cycle with no critical speed limitations and are available in much longer lengths than screw drives. These benefits make timing belt drives ideal for long stroke applications requiring high linear velocity and acceleration. Length of stroke of a timing belt actuator is limited only by the ability to efficiently tension long strands of the timing belt.

On the downside, timing belt drives have reduced load-carrying (thrust) capacity compared to screw drives. They also have lower accuracy and repeatability. There are no good methods for estimating service life. Belt drives are more sensitive to impact loads, and some timing belt materials are prone to gradual elongation during operation, which requires periodic tensioning. Improperly tensioned long belt drives could slip (jump teeth) at high accelerations. Belt drives often require speed reduction to overcome high inertia associated with loads and pulleys. Vertically positioned belt drives require emergency brakes to prevent backdriving under the weight of load at power loss. Timing belts are available in various materials, sizes, widths and tooth geometries.

The choice of belt material is determined by the application’s tensile strength and elasticity requirements. The size and width of a belt are determined primarily by the amount of torque to be transmitted.

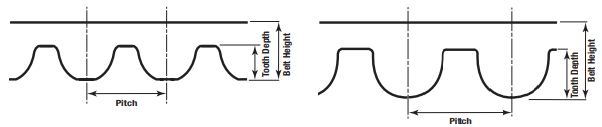

Selection of timing belt geometry and pitch (distance between two adjacent teeth) are also important for strength, but selection is also made based on the type of application and its parameters (speed, accuracy and repeatability of linear positioning, environmental factors, noise, etc.).

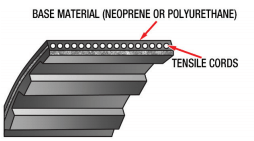

Fig. 4. A typical timing belt construction

1. Timing Belt Materials

Timing belts are typically made of a flexible polymer material molded over reinforcing tensile cords. The most commonly used materials are neoprene and polyurethane belts with steel cords or fiberglass, aramid (Kevlar) or carbon fibers, sometimes with additional nylon tooth facing.

Fiberglass tensile cords typically provide a very low elongation but are not well suited for impact or shock loading. They are lower in tensile strength than steel, aramid or carbon. Aramid (Kevlar) fibers also have a low stretch, but have a high tensile strength and good shock load resistance.

In addition to high strength and excellent shock resistance, steel cords provide better high-torque operation at low speeds and better positioning accuracy.

2. Timing Belt Tooth Geometry

Timing belts commonly have curvilinear tooth profiles. The curvilinear timing belt profiles such as HTD® and PolyChain GT2® have excellent qualities, including high shear strength, good positioning accuracy, light construction, very low stretch, longer life, quieter operation and lower cost. The deeper tooth design of these profiles increases resistance to slippage (cogging, jumping teeth).

PolyChain GT2® timing belts are available in some of the actuators as special equipment for custom high-thrust configurations.

Fig. 5. Timing belt tooth geometry

SUMMARY

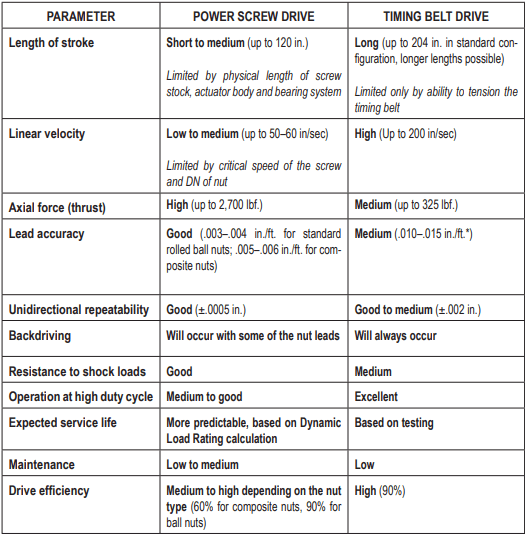

Many applications make the choice of a linear drive easy. For example, timing belt drives are ideal for long-stroke applications requiring high linear velocity and acceleration. The length of stroke of a timing belt actuator is limited only by the ability to efficiently tension long strands of timing belt. If the application stroke length and speed are moderate, but the axial thrust is high, and (or) if a high positional accuracy is required, then power screw drives are an ideal fit.

When the choice isn’t as obvious, consider all available application parameters to make a good selection.

Some broad guidelines for a linear actuator drive type selection are given in Figure 5 below. The strokes, speeds, force, accuracy and repeatability numbers will vary with rodless actuator manufacturers. The numbers below reflect Tolomatic rodless actuator specifications, but the general comparisons between screw and belt drives will be similar.

* With properly tensioned belt

Fig. 5. General guidelines for linear actuator drive type selection.