Machine design, clean in place (CIP) and linear actuators

Keeping clean is important, right? Well, in food and beverage processing and pharmaceuticals manufacturing keeping equipment clean is essential. Cross-contamination among batches causes problems, and food or beverage residue can grow harmful microorganisms. Many plants have clean in place (CIP) systems that deliver cleaning tailored to the needs of the facility including cleaning action (force, turbulence, direction), timing/duration (when, how often, how long), temperature, and type/strength of cleaning agent.

When you design equipment for these industries you need to keep cleanability in mind. Even components like electric linear actuators must stand up to cleaning procedures.

Ball and roller screw linear actuators: How to compare service life

When you’re designing equipment, you'll probably be asked, “How long will this machine last?” And even if you’re not asked outright, you know service life is an essential consideration. It’s a critical factor you consider when sourcing components.

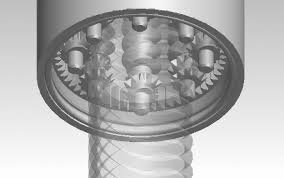

Electric linear actuators are important components in many machines, and the “how long will it last” question is a familiar one. If it’s a ball or roller screw actuator, you can use a formula to help estimate life based on load – the same formula used to estimate bearing life.

Corrosion resistant integrated linear servo actuator is high force

The electric rod actuator is an industrial workhorse, one you’ll find in a wide range of machine tool, conveying and positioning applications. A familiar mechanism, yes. But identifying one that’s compact, corrosion resistant and can deliver high force is a tall order. A corrosion resistant integrated linear servo actuator can be the answer.

Hydraulic vs high force electric linear actuators: new infographic

Choosing the best linear actuator for a task takes a thorough understanding of the application. The basics like the weight of the load, the distance the load’s to be moved, and the speed and force needed are all important factors. A machine designer may also need to consider variables like environmental conditions, data collection and reporting, as well as flexibility/programmability requirements.

If the application calls for a high force linear actuator, the usual solution has been a hydraulic cylinder. However, high force electric linear actuators are now available (many with roller screws) and offer distinct advantages. Our new infographic compares the performance of electric, hydraulic and servohydraulic actuators on intelligence and operational parameters.

Electric linear actuator ebook: A resource

Industrial automation counts on the reliable motion control that linear actuators provide. Lately, electric linear actuators have gotten more popular because they offer better control of variables like speed, acceleration, position and force than pneumatic or hydraulic cylinders. Electric actuators also offer superior accuracy and repeatability, as well as programmable control that can handle even complex motion profiles. In many applications, they can do all this at a lower cost of ownership than pneumatic or hydraulic actuators.

Electric high force linear actuators with roller screws rival hydraulic

When you’re specifying a high force linear actuator, your application’s requirements call the shots. It used to be that hydraulic cylinders were your only recourse when high force was needed. Now there are electric linear actuators with roller screws that rival the high force, high thrust, high torque capabilities of hydraulics. Plus, these electric actuators deliver high speed, great accuracy and repeatability and long life. Electric roller screw actuators are definitely an alternative to consider.

Choosing the right linear actuator [INFOGRAPHIC]

When your design calls for a linear actuator, you have lots of choices. Pneumatic, electric, rodless, rod, belt driven, screw driven. These are just some of the options available.

High force linear actuator: electric replaces hydraulic

It used to be that when a machine designer was confronted with a high force linear actuator application, the only solution was a hydraulic cylinder. That meant the designer had to factor in the bulky hydraulic power unit (HPU), the inevitable leaks of hydraulic fluid and the downtime produced by frequent maintenance.

Now there’s another option when a high force linear actuator is needed. There are electric linear actuator products that can meet demanding specifications with ease.

Electric linear actuator accuracy and repeatability webinar

When an engineer is developing a machine design, accuracy is often top-of-mind. So is machine cost. But these two considerations can be at odds since the usual scenario is that the higher the accuracy of a device, the higher the cost. This certainly holds true for electric linear actuators and linear motion systems.

Electric linear actuators meet the challenge of FSMA

The federal Food Safety Modernization Act (FSMA) that was enacted in 2011 has energized the food industry around food safety and the prevention of food-borne illnesses. Most of the major producers and food equipment manufacturers have kept ahead of FSMA requirements successfully since food safety and prevention have always been among their top priorities.

Ask an Engineer

Ask an Engineer