High force linear actuators – hydraulic vs electric [WEBINAR]

By Tolomatic on June 27, 2017

When your application calls for a high force linear actuator, you may believe that your only choice is a hydraulic cylinder. Hydraulics have long been the leading choice for automation equipment needing high force. However, now there are electric high force linear actuators that offer important advantages over hydraulics in terms of performance and total cost of ownership. Watch this webinar, and you may want to reconsider the merits of using an electric rod actuator.

When your application calls for a high force linear actuator, you may believe that your only choice is a hydraulic cylinder. Hydraulics have long been the leading choice for automation equipment needing high force. However, now there are electric high force linear actuators that offer important advantages over hydraulics in terms of performance and total cost of ownership. Watch this webinar, and you may want to reconsider the merits of using an electric rod actuator.

If you’d like to dig deeper into the subject, here’s a white paper comparing hydraulic cylinders and electric rod actuators for high force applications.

Comparing hydraulic and electric high force linear actuators

1. Force

In hydraulic cylinder systems, Force = Pressure x Area so even a 3-inch cylinder at 2200 psi can achieve 15,000 lbf (66,723.3 kN). However, hydraulic cylinders often are oversized so an application's actual force requirements may be obscured. A hydraulic actuator must wait for pressure to build until force is achieved.

Electric linear actuators use current passing through the servo motor to produce torque that drives the power screw and generates force. Many electric high force linear actuators use roller screws which have excellent force transmission capabilities. With an electrical actuator, force is instantaneous.

2. Control

A hydraulic actuator works well in simple, end-to-end position applications. However, complex motion profiles may require expensive servo hydraulic systems.

An electric linear actuator with a servo motor offers infinite control over position, velocity, acceleration/deceleration, output force, and more. Adjustments can be made on the fly, plus accuracy and repeatability levels are far better than those of a hydraulic system.

3. Velocity

Delivering high force at high velocity can be difficult for both hydraulic and electric actuators.

For a hydraulic cylinder to achieve high speeds at higher forces there must be enough pressurized oil in the system to push the oil in the cylinder in the required time. An accumulation system may be needed to hold the pressurized volume.

An electric actuation system depends on motor RPM, torque, and screw characteristics to deliver high force. But speed is limited because as a servo motor gets larger, torque will increase but RPMs will decrease.

On the positive side, though, because an electric actuator has control over the entire motion profile, it doesn’t have to stroke the entire length of each cycle. The actuator may be able to deliver peak velocities since it can execute shorter, more intelligent moves.

4. Footprint

A hydraulic cylinder itself has a compact footprint at the work point, but the hydraulic power unit (HPU), which regulates oil pressure and flow, requires a lot of floor space. Plus, additional components (heat exchanger, gauges, accumulator, cables, and more) may be needed.

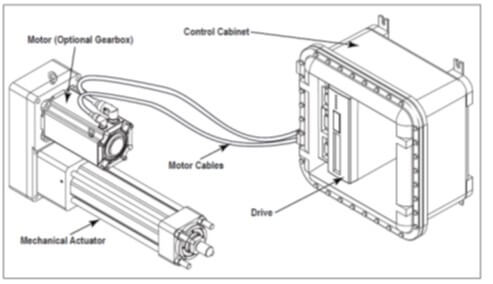

An electric actuator has a small overall footprint with its combination of actuator, motor, drive, cabinet, and cables. An electric servo actuator system takes up only a fraction of the space needed for a hydraulic cylinder with HPU.

An electric actuator has a small overall footprint with its combination of actuator, motor, drive, cabinet, and cables. An electric servo actuator system takes up only a fraction of the space needed for a hydraulic cylinder with HPU.

5. Temperature sensitivity

Hydraulic systems are sensitive to temperature. The oil gets thicker and slower-moving  in the cold causing sluggish and inconsistent performance. High temperatures from overheating or the environment may degrade oil and ruin seals.

in the cold causing sluggish and inconsistent performance. High temperatures from overheating or the environment may degrade oil and ruin seals.

An added tank heater can maintain operating temperature in the cold while a heat exchanger can mitigate overheating. The addition of either piece of equipment adds to system costs.

Electric actuation systems are much less temperature-sensitive since they can be selected to run at a designated temperature for the given amount of work required. Electric actuators can be specified with extreme temperature grease for fast response in the cold.

6. Life and maintenance

Hydraulic cylinders are rugged devices that offer long service life when maintained properly. However, maintenance requires staff time, components (new seals, oil, and filters), and machine downtime.

If the electric linear actuator is sized correctly for the application, there is no maintenance required so there is no downtime. Proper electric rod actuator selection starts with an accurate calculation of actuator life. For correct sizing, rely on sizing software and the advice of a linear motion specialist.

7. Data collection

Basic hydraulic actuation systems do not have data collection and reporting capabilities. Only expensive, complex servo-hydraulic systems can track and monitor position, velocity, force, etc. at the work point.

Sensing capability is built into an electric actuator’s servo system. Motor current monitoring tracks force and repeatability. The motor’s feedback device registers position and velocity. Reporting is done through the drive and PLC.

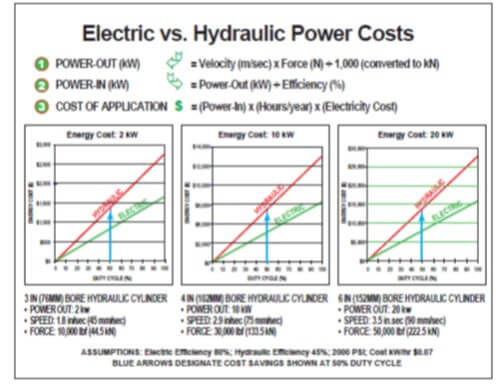

8. Electricity costs

Hydraulic systems are typically 40-55% efficient in converting electrical power to motion.

Hydraulic systems are typically 40-55% efficient in converting electrical power to motion.

Electric linear actuator systems typically operate in the 75-80% efficiency range.

9. Environmental impact

The unfortunate fact is that hydraulic actuation systems leak. Leaks create safety hazards, contaminate products, and pollute the environment. Clean-up is costly.

Electric actuation is one of the cleanest linear motion technologies. Grease on the roller screw is the only potential contaminant, and special greases (food grade, clean room, etc.) can be specified.

Cost of ownership

There are different ways to look at the cost of any machine or component. One way is to only consider purchase price. This certainly keeps things simple but may not tell the whole story. Another is to look at cost through the lens of “total cost of ownership”. This method requires that you look at the machine or component in terms of ongoing costs, like use of electricity, maintenance requirements (staff, parts, downtime), and even product quality/wastage.

When all factors are considered, the low initial purchase price of a hydraulic cylinder may not overcome its high ongoing costs. Total cost of ownership of hydraulic actuation systems can be very high. On the other hand, an electric rod actuator’s high purchase price may be offset by its long-term operating efficiency.

Learn more

Our white paper comparing electric rod actuators and hydraulic cylinders will give you the information you need to find the right high force linear actuator for your application. Download it here.

Interested in electric linear motion? Join the discussion at our LinkedIn group. Just click here.