Converting From Hydraulic to Electric High-Force Linear Actuators with Force Feedback

By Ryan Klemetson on April 30, 2019

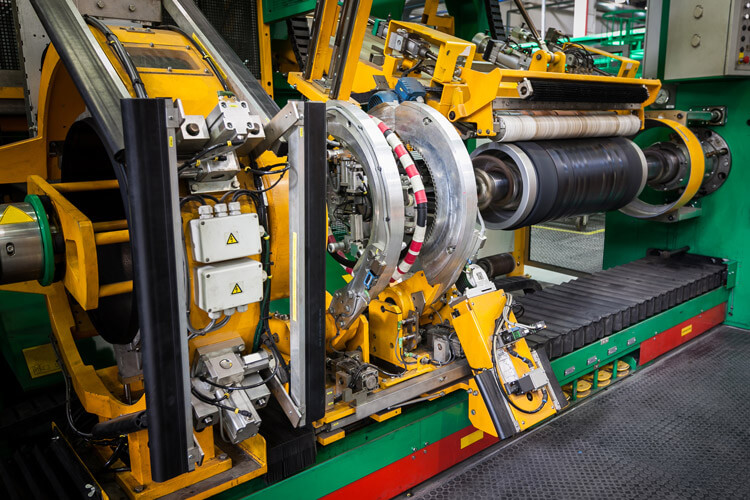

Got a high-force linear motion application you’re responsible for? If you do, you’re likely always on the lookout for solutions to make things work more efficiently. The first thing that comes to mind for most are hydraulic cylinders — after all, they’re inexpensive, compact and power-dense.

Got a high-force linear motion application you’re responsible for? If you do, you’re likely always on the lookout for solutions to make things work more efficiently. The first thing that comes to mind for most are hydraulic cylinders — after all, they’re inexpensive, compact and power-dense.

Here’s the challenge, though: hydraulic cylinders are prone to leaks. They also have higher operation and maintenance costs than newer alternatives like electric high-force linear actuator solutions.

Machine designers have a choice: stick with something familiar and less efficient or make the (surprisingly easy) switch to a linear motion solution that can support their future growth.

Let’s take a closer look at why it’s more cost effective than you’d think to convert from a hydraulic cylinder to an electric linear actuator — including the unique benefits found in high-force applications with help from torque monitoring and load cells.

We’ll start with a video explaining how the process of converting from hydraulic to electric linear actuators works — then you can keep reading to learn how beneficial it can be.

What benefits do electric high-force linear actuators have vs. hydraulics?

Force

Electric linear actuators use current to produce torque that drives the screw assembly and generates force. Many electric high-force linear actuators use roller screws which have excellent force transmission capabilities (40,000 lbf, 178 kN, and higher).

Electric linear actuators use current to produce torque that drives the screw assembly and generates force. Many electric high-force linear actuators use roller screws which have excellent force transmission capabilities (40,000 lbf, 178 kN, and higher).

With an electrical actuator, force is instantaneous. Without extra equipment or additional considerations, a hydraulic actuator has to wait for pressure to build.

A high-force electric linear actuator with a force feedback sensor (like a load cell) can do more than just operate effectively — it also measures the force being applied during motion at all times and relays that information back to you. Being able to analyze this data means being able to consistently improve operational efficiency.

Control of variables

An electric linear actuator with a servo motor can control position, velocity, output force, acceleration/deceleration and more. Adjustments are quick, plus accuracy and repeatability are far better than a hydraulic system.

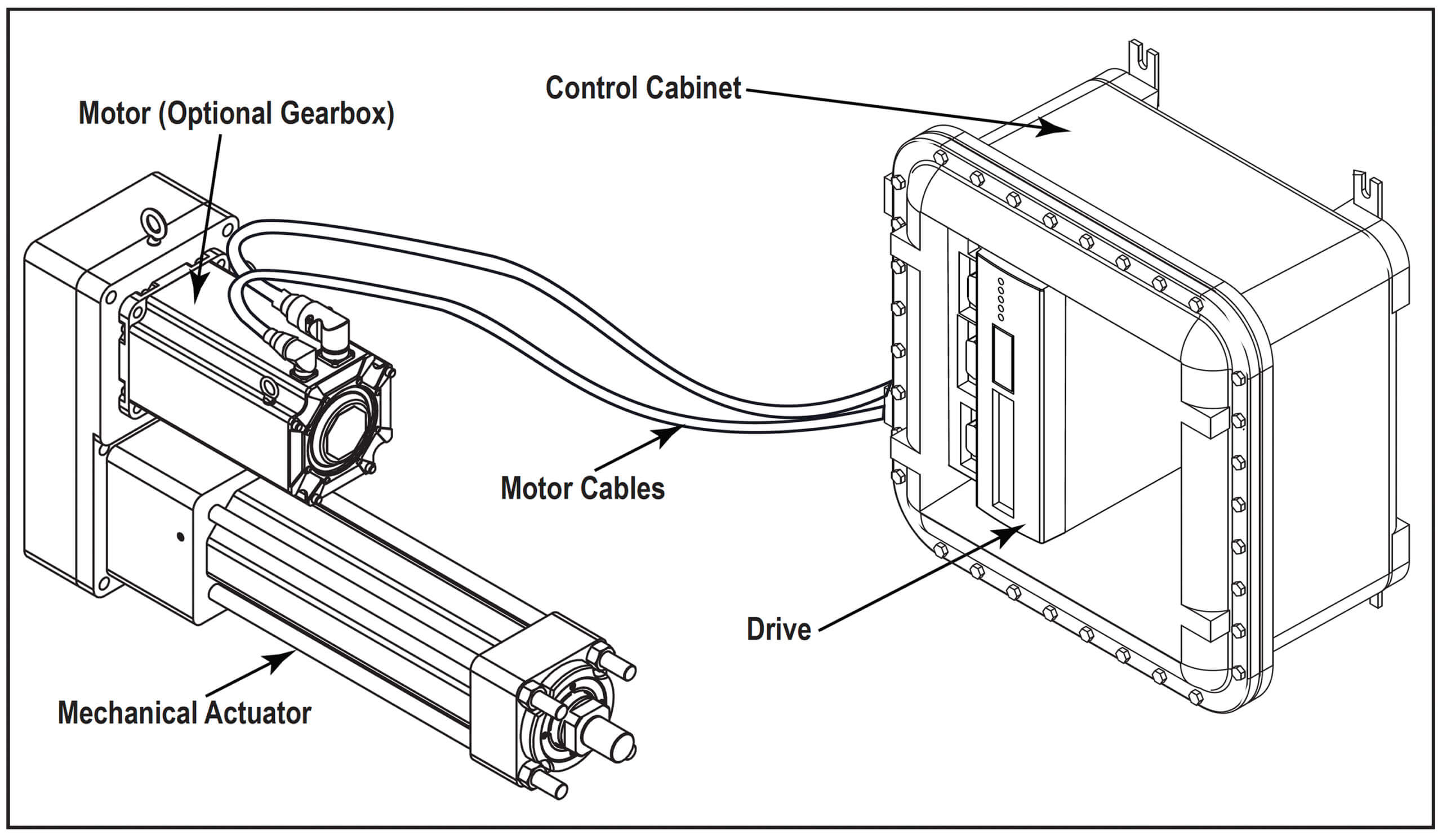

Footprint

Footprint

An electric servo actuator system (actuator, motor, cables and drive) takes up only a fraction of the space needed for a hydraulic cylinder with HPU.

Temperature sensitivity

Electric actuators offer improved performance at extreme temperature ranges because they are designed to run in these conditions. Hydraulic systems often suffer from sluggish and slow performance during start up in cold temperatures and degradation of hydraulic fluid in hot temperatures.

Life and maintenance

If the electric linear actuator is sized correctly for the application, there is minimal maintenance required so there is no unexpected downtime. Proper electric rod actuator selection starts with an accurate understanding of thrust force and calculations for actuator life.

Did you know that we offer sizing software to help make choosing the right electric linear actuator easy? Sign up and give it a try!

Data collection

Sensing capability is built into an electric actuator’s servo system. Motor current-monitoring tracks force and repeatability. The motor’s feedback device registers position and velocity. Reporting can be accomplished through the drive and PLC.

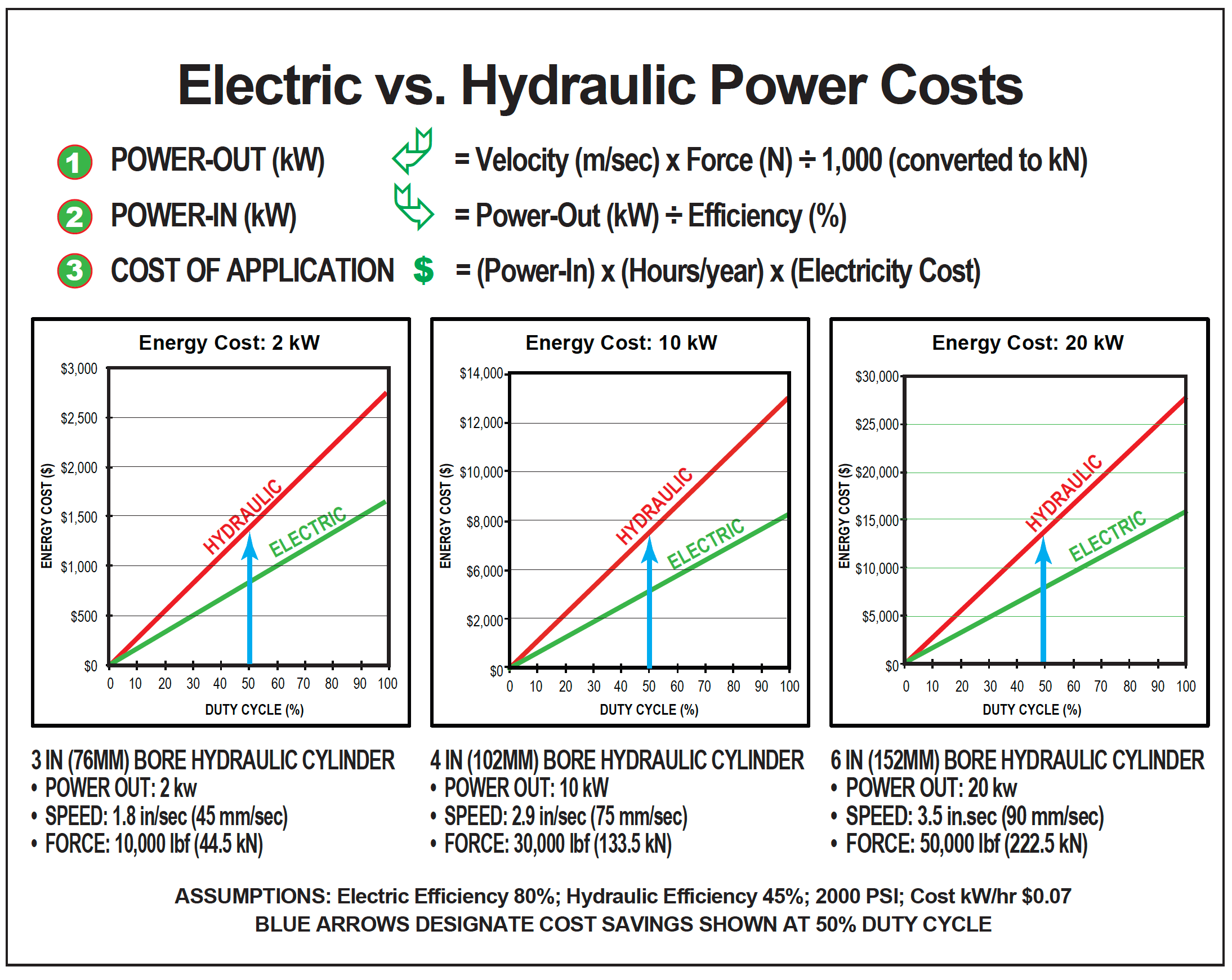

Electricity costs

Electricity costs

Electric linear actuator systems are very efficient, typically operating at 75 to 80 percent efficiency, so they use less power than hydraulic systems. Hydraulic systems are only 40 to 50 percent efficient.

You can learn more about how these calculations are made by visiting our Electric Rod Actuators vs. Hydraulic Cylinders: A Comparison whitepaper.

Environmental risks

Hydraulic systems leak which can create safety hazards, contaminate products and pollute the environment. Clean-up can be costly.

Electric actuation is one of the cleanest linear motion technologies. Grease on the screw is the only potential contaminant. Special greases (food grade, cleanroom, etc.) are available for different applications to further minimize potential contamination.

The bottom line

In the long run, an electric rod actuator’s higher purchase price is offset by its long-term operating efficiency. Utility costs are lower, and there’s superior process control and reporting which improves product quality. Linear actuators with force feedback sensors like load cells offer added operational data that helps improve efficiency Electric roller screw actuators offer long service life with no messy, costly leaks. In many applications, electric actuators offer lower total cost of ownership than hydraulic systems.