Electric Rod Actuators vs. Hydraulic Cylinders: A Comparison

Introduction

Hydraulic cylinders, known for high force at an affordable cost, have been widely used in factory automation equipment and other special automation equipment for decades. Hydraulics are rugged, relatively simple to deploy and provide a low cost per unit of force. In recent years, electric rod actuators (cylinders) have become more flexible, precise and reliable with increasingly larger force capacities. These advancements have created an ongoing debate over which technology—hydraulic cylinder or electric actuator—offers the best overall solution.

Hydraulic Cylinder vs. Electric Linear Actuator: Motion Control Capabilities

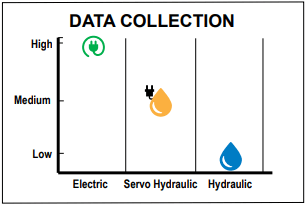

The main reason engineers select an electric actuator system over a hydraulic cylinder system is the flexibility of its motion control capabilities: position control (multiple positions, accuracy); velocity control; control of acceleration/deceleration; control of output force; and complex control of all these motion variables on the fly. Electric actuators, coupled with a servo drive and motor system, have infinite control over position. Accuracy and repeatability of position are far beyond the capabilities of a hydraulic system.

Standard hydraulics are great for end-to-end position applications, but mid-stroke positioning is more complicated, requiring a control valve and operator assistance. Mid-stroke positioning is open loop and requires an operator to decide which position is acceptable. Additionally, speed control is monitored through a control valve and again requires an operator to dial in the acceptable speed for an application, but reaching an exact speed setting is often difficult to achieve. Once the speed setting is adjusted, the pressure force output required from a hydraulic cylinder is regulated through the pressure valve. Finally, the repeatability of position, speed and force of a hydraulic cylinder are subject to worn seals, leaks, pressure drops and spikes from the pump and other maintenance factors. It is difficult to get repeatable performance from day-to-day, month-to-month or year-to-year in a production environment when oil quality and viscosity change due to temperature variations. Obtaining the desired performance level will require constant operator intervention.

More advanced hydraulic systems, called “servo-hydraulic,” can precisely control position, velocity and force, but they require additional components—a servo controller, an electrohydraulic servo valve, and a position feedback device such as a linear transducer—which add significant complexity, space and cost. These components control the pressure and flow into the hydraulic cylinder, similar to how a servo drive controls current to a servo motor. Hydraulics also have even more advanced controllers, which allow multiple axes to be coordinated together. However, this is rare in hydraulics system implementation, and these controllers add extreme complexity and cost to the overall system. In addition, they can be quite sensitive and need regimented maintenance to ensure desired performance.

Figure 1: Control over all aspects of motion can be extremely important in critical applications where precise position, speed and force come into play. This chart shows the control capabilities of the three technologies.

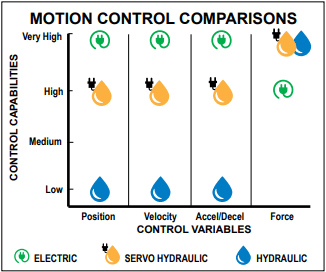

When combined with a servo control system, electric actuators offer more than infinite control and superior accuracy and repeatability. Multiple-axis servo controllers are readily available off-the-shelf on most modern control systems today. Controllers and electric actuators are more easily and cost effectively coordinated together in complex configurations over more limited hydraulic varieties. Velocity of one or multiple electric actuators is precisely and accurately controlled at all times and can easily blend from one speed to another without stopping or overrunning position. Acceleration and deceleration control means that electric actuators will not “bang” into hard-stops or jolt into action. This eliminates stress on frame elements and the need to over-engineer structures to withstand shock loads. All movements will be smooth—allowing electric actuators to be used in mission-critical processes where machine vibrations are not acceptable or process speed is affected. Force is controlled through current to the servo motor. Since servo controllers have precise control over current, almost all electric actuators provide accurate and repeatable control of force output at the work point.

Figure 2: This chart shows different motion profile positions at different velocities with different accel/decel rates, all under full and precise control.

Finally, an important feature of electric actuators is their ability to provide programmable control of all the motion profile variables. As a result, the only operator interaction required is the up-front design time to build desired performance variables into a PLC or another controller’s programming environment. Once set, the operation repeats from day-to-day, month- to-month and year-to-year. Furthermore, with the use of HMI (Human Machine Interface) screens, the variables of position, velocity, acceleration/deceleration and force can be easily changed at any time, providing maximum flexibility. In an OEM environment, system performance will be easier to control due to the increased consistency of an electric vs. a fluid system.

Hydraulic Cylinder vs. Electric Linear Actuator: System Components

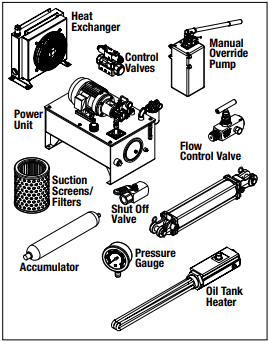

Figure 3: Hydraulic system components

The number of components and overall space required for a hydraulic cylinder system is much greater than an electric system. Hydraulic systems require:

- A cylinder

- A power unit to provide oil pressure

- Control and accessory valves

- Filters

- Hoses

- Fittings

- Additional components

Hydraulic cylinders offer a compact footprint at the work point (where the power density is required), but the hydraulic power unit (HPU) which regulates flow and pressure to these actuators and other components, can require a large footprint in floor space. HPUs are not small and typically are placed near the actual cylinder itself, further increasing the system footprint. In very large systems with remote mounted HPUs, long lengths of hose can decrease the overall rigidity and efficiency of the hydraulic system.

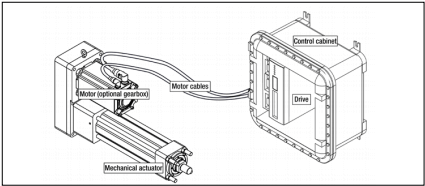

Figure 4: Electric system components

Electric rod actuators provide a smaller overall footprint. These systems utilize a mechanical actuator; a motor (servo, or other); an optional gearbox; cables; and a drive/amplifier, which is usually mounted in a control cabinet.

Although the electric actuator—due to its design of integrating a power screw and bearing system—does require additional length over a hydraulic cylinder, when considering the overall system footprint, this additional length is more than compensated for by the much smaller footprint of the servo drive—the functional equivalent of the HPU. Typically, automation equipment utilizes a control cabinet and can be designed for an additional drive. Size requirements for a servo drive are normally a fraction of the size requirements of a HPU.

In new system designs, if the additional space at the work point can be made to accommodate the electric actuator’s working stroke and overall length, the overall footprint of the machine can be greatly decreased by eliminating the need for large power units.

Hydraulic Cylinder vs. Electric Linear Actuator: Force Capabilities

Due to their high operating pressures, hydraulic cylinder systems are great at producing extremely high forces. Typical pressures range from 1800 to 3000 psi (124.1 to 206.8 bar). In some high-pressure hydraulic systems, pressure ratings up to 5000 psi (344.7 bar) are used to further emphasize power density. Since hydraulic cylinders operate on the Force = Pressure x Area fluid power principle, the high pressures allow smaller cylinders to reach very large forces. For example, 3-inch and 5-inch bore cylinders at 2200 psi could achieve approximately 15,000 lbf (66,723.3 kN) and 43,000 lbf (191,273.5 kN), respectively. However, hydraulic cylinders are not usually used to their full output force capability; they are typically oversized to improve control.

When considering electric actuators, it is important to determine the working force required. To estimate the approximate force required for an electric actuator, the typical approach is to adjust the hydraulic work port or system pressure until the operation can no longer be performed. Electric actuator systems rely on current through the servo motor to produce torque to the mechanical system, which drives the power screw to turn and generate force. This is a huge advantage; force is instantaneous. In hydraulic systems, where system rigidity is not optimized, the hydraulic actuator must wait for pressure to build until force is achieved. Another big advantage with electric systems is that the servo controller automatically regulates the current. The electric actuator system essentially uses current “on demand.” Any adjustment happens automatically. A hydraulic power unit must always keep pressure in the system for the hydraulic cylinder to actuate, which can be highly difficult.

When selecting an electric actuator system, it is important to consider the motor’s RPM and torque capabilities, coupled with the screw lead in the electric actuator. Matching speed and torque from the servo motor with the lead screw’s mechanical output can be complex. Achieving the extreme forces that hydraulics can produce is entirely possible with electric technology, but typically, the electric actuator deployed will have a larger body diameter and the electric actuator system will have a velocity maximum that can’t be exceeded. The complexity in sizing a system can easily be overcome as actuator and servo component manufacturers provide easy-to-use motion control sizing software packages that factor in all these variables.

Hydraulic Cylinder vs. Electric Linear Actuator: Velocity Capabilities

Achieving high velocities at high forces presents challenges for both hydraulic and electric technologies. Hydraulics require pressure for force and flow for speed. To achieve higher speeds at higher forces, there must be enough pressurized oil in the system to basically push the required volume of oil into a cylinder in the required amount of time (defined as flow). This typically requires an accumulation system to hold the pressurized volume. The problem can multiply with long stroke cylinders; uncharged accumulators may starve the system of oil. In the end, deploying additional capacity in hydraulic accumulator systems allows them to achieve high speeds at high forces. The downside of this practice is that without servo-hydraulic control on the hydraulic system, excess energy (force x velocity) is essentially being utilized in an open loop control scheme.

As stated earlier, the force capabilities of an electric actuator system depend on the right combination of servo motor RPM, servo motor torque and mechanical advantage from screw lead and possibly a gearbox. As servo motors increase in size, torque typically increases significantly but RPMs decrease. In extreme applications of force and speed, the only way an electric actuator system may be able to achieve the desired performance is to grossly oversize the system—which can be cost prohibitive. Alternately, remember that an electric actuator system has complete control over the motion profile; it doesn’t have to stroke the entire length of each cycle. Plus, with control of acceleration and deceleration, the electric system can settle more quickly, which reduces cycle time and increases efficiency. Finally, electric actuator technology may alleviate some of the peak velocities required as more intelligent, shorter moves can be executed.

How do electric actuators perform over hydraulic cylinders in harsh temperatures?

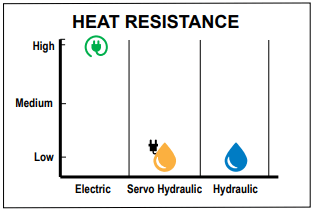

Heat

A major problem for hydraulic systems is heat management. The inefficiencies of hydraulic systems cause overheating. Hydraulic fluid temperatures above 180°F (82°C) damage most seal compounds and accelerate degradation of the oil. Circuit design can play a big part in generating heat. Hoses, fittings and other components can be a factor if they are inaccurately sized for the flow requirements. Sophisticated load-sensing systems can mitigate most heat issues, but can be costly. Heat exchangers are an economical way to manage this without significantly over-sizing your reservoir and ultimately your HPU footprint.

Figure 5: Compared to hydraulic cylinder systems, electric systems are better at managing heat resistance.

There are two ways to solve overheating problems in hydraulic systems: decrease heat load or increase heat dissipation. Hydraulic systems dissipate heat through the reservoir, by having the correct level of oil or use of a heat exchanger. Keeping a hydraulic system in proper form to manage heat will require constant attention and maintenance.

Electric actuators can overheat at times, but the cause is usually due to extreme changes in duty cycle or running the actuator harder than it was designed or sized for. Extreme changes in the ambient temperature not accounted for in the design may also cause overheating, but these conditions are exceptions and typically would not occur in most factory automation environments. Due to their higher efficiency and sizing accuracy, electric actuator systems can be selected to run at a desired temperature for the given amount of work required. Accurately predicting temperature allows the electric actuator system to perform consistently without affecting the life of the device.

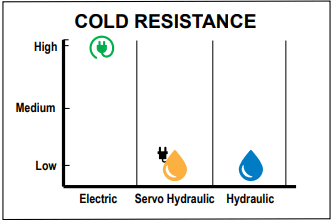

Cold

Cold temperatures present other problems for hydraulic systems. Cold oil causes sluggish and inconsistent operation until the oil is warm—which in turn causes large swings in force and speed. Hot to cold temperature swings can also affect the integrity of the rod seal—a critical component that helps to prevent leaks and contamination. Oil tank heaters can manage start-up temperatures, but they are an extra component and expense.

Electric actuators, on the other hand, can be deployed with extreme temperature grease which allows for quick, effective starts in cold temperatures. There is usually a small performance difference in force repeatability from a cold to a warm temperature. This difference is acceptable in most applications, often making it preferable to choose electric over hydraulic actuators.

Figure 6: Electric systems are not susceptible to fluid thickening in cold temperatures and perform consistently despite fluctuations in temperature swings

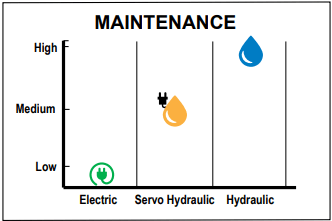

Hydraulic Cylinder vs. Electric Linear Actuator: Service Life and Maintenance

Hydraulics are rugged, widely used devices that can have a long service life. The trade-off is that they require frequent maintenance and attention to achieve the desired performance over the life of the system. Maintaining the integrity of the rod and piston seals is key to repeatability because these are the main elements that contain the pressure required for motion and force. If these components wear or are damaged, they must be replaced. Otherwise, force will be reduced at initial pressure or “blow by” will affect speed. Changing oil filters and oil on a periodic basis are additional maintenance tasks. Contaminated or degraded oil can also severely affect the operation of the system. Neglecting maintenance items will lead to leaks or contamination and premature failure of components.

Figure 7: Electric systems require little or no maintenance compared to hydraulic systems.

On the other hand, electric actuators sized for the life of an application require no maintenance. The main power elements of an electric actuator are the power screw and other thrust-bearing elements. These elements have a Dynamic Load Rating (DLR) specification that can be utilized to estimate the amount of work (force over distance) an electric actuator can achieve. Utilizing an industry standard L10 life estimation, electric actuators can be estimated with 90% reliability to last in an application.

Need help estimating the right lifespan for ball and roller screw actuators? Check out our guide.

These power elements are typically greased for life, but easy, in-field greasing methods can be applied if necessary. The other wear element on an electric rod-style actuator is the rod seal, designed to hold out water, dust and other environment contamination from the actuator’s internal components. Unlike hydraulic cylinder seals, there is no pressure to hold in the actuator for proper operation. Even if the seal fails, the actuator will continue to operate. Rod seals on most electric actuators are easily and inexpensively replaced if damage occurs. Misuse is the primary reason that electric actuators fail. Exceeding the actuator’s performance specifications for extended periods of time or gross neglect are the most common misuse factors.

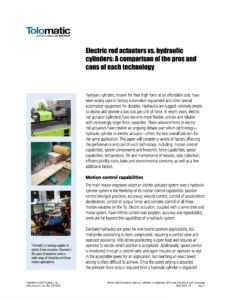

Hydraulic Cylinder vs. Electric Linear Actuator: Data Collection

In the never-ending quest to improve manufacturing processes, data collection in critical areas is becoming more and more prevalent in today’s manufacturing environment. Hydraulic cylinders require expensive, complex servo-hydraulic systems with additional sensors to track and monitor position, velocity, force and other factors happening at the work point. These factors are all built into an electric actuator’s servo system. Monitoring the motor current makes it easy to track force and repeatability. The feedback device on the motor registers accurate position and velocity.

Figure 8: Electric actuator systems provide the most data collection capabilities over servo hydraulic and conventional hydraulic systems.

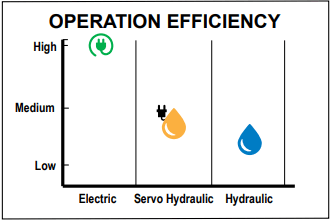

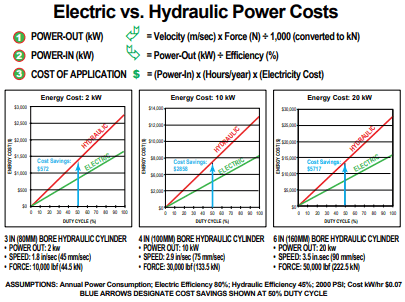

Hydraulic Cylinder vs. Electric Linear Actuator: Efficiency and Cost

Electric actuator systems typically operate in the 75-80% efficiency range for the work they complete; hydraulic actuator systems typically operate in the 40-55% efficiency range. An additional factor in the electric utility cost equation is that electric actuators only demand current to the motor when it is required. When electric actuators are at rest, they require no current or very low amounts of current to hold their positions. Hydraulics require that the power unit keep the hydraulic system pressurized at all times when the system is turned on—resulting in inefficient use of power.

Figure 9: Compared to servo hydraulic and conventional hydraulic systems, electric systems operated far more efficiently.

Below are three application examples that show the power usage of electric vs. hydraulic actuator systems.

Figure 10: The above charts show the difference in utility costs for a hydraulic and an electric cylinder. The blue arrow depicts cylinder operation at 50% duty cycle and the resulting estimated utility costs.

By dividing the efficiencies of the two technologies into one another, an approximate factor can be determined on electric utility cost based on when the actuators/cylinders are actually moving.

For example: 80% (electric) / 40% (hydraulic) = 2. This results in electric being twice as efficient or hydraulic taking twice as much power to do the same work. This is an approximation, but it is not far from reality. In fact, unless a hydraulic system is properly maintained, the overall efficiency of the system can drop to 20%, making electric technology up to 4 times as efficient (or hydraulic utility costs up to 4 times higher).

Although electric actuator systems are twice as efficient as hydraulic cylinder systems, an electric servo solution can be more expensive to implement initially. But the cost over the life of the system can be substantially less when considering the increased performance, system flexibility and decrease in utility costs.

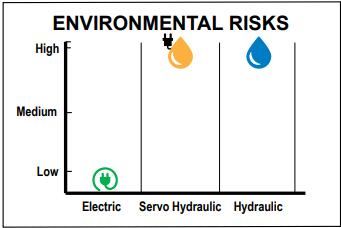

Hydraulic Cylinder vs. Electric Linear Actuator: Leaks and Environmental Concerns

Many hydraulic industry professionals have said, “It is not a matter of IF hydraulics will leak, but a matter of when and by how much.” Leaks create messes in the manufacturing environment and also present a safety hazard if someone slips on the spill. More alarming is leaks could cause serious contamination to key processes and products—such as food processing, pharmaceuticals, medical devices and others. A contamination event can be costly both in terms of clean-up and scrapped product—and even more costly if the contaminated product reaches consumers and is then recalled. Additionally, many hydraulic systems are deployed outdoors and in the vicinity of living spaces and fresh water. Leaking oil into the surrounding environment can be a major concern for communities.

Figure 11: Unlike hydraulic systems, electric systems present minimal environmental risk.

Electric actuator technology is one of the cleanest linear motion technologies that can be actively and easily deployed. Grease on the lead screw is the only potential contaminant; special greases (food grade, clean room, etc.) can be applied if required. The high-quality seals used on the rod of the electric actuator keep grease inside the actuator, virtually eliminating contamination issues.

Other Factors to Consider When Comparing Electric Over Hydraulic Actuators

Noise: A noisy power unit running a hydraulic cylinder can be a noise polluter for any operator near the machine.

Shock loads: Hydraulics are good at handling shock loads. Hose compliance (unless hard plumbed) and oil bypassing along the main or work port relief valve absorb shock loads. In addition, internal leakage within the cylinder and valves can also offer compliance with shock load conditions. A large shock load in-line with the rod would be absorbed in most cases by the piston against the compressed oil in the body of the hydraulic actuator. On the other hand, shock loads on an electric actuator’s lead screw or bearing system may affect performance. Electric actuators may have to be oversized in order to handle shock loads or use external shock absorbing mechanisms to prevent damage.

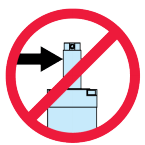

Side loads: Side loading—due to misalignment or pressure from a moment arm—places stress on the rod and piston seals of a hydraulic cylinder. The seals may wear prematurely or fail completely, resulting in poor performance and eventually premature failure of the cylinder. Electric actuators don’t like side loading either, but for different reasons. Side loading puts stress on the actuator’s front rod seal and on the nut of the lead screw. The rod seal may fail, allowing contaminants into the actuator and causing premature failure of the electric actuator. Side loading the lead screw nut can diminish the estimated life of the ball or roller screw. However, unlike hydraulic actuators, electric actuators typically deploy an anti-rotate mechanism on the lead screw nut of the actuator, which allows it to absorb some side-loading due to mounting misalignment. Finally, both hydraulic and electric cylinders require care and consideration when mounting to make sure the cylinder is in alignment with the system it is intended to move.

Interested in making sure your linear motion results stay consistent? Read our alignment guide.

Figure 12: Side loading of rod actuators is not recommended because it places stress on internal actuator components.

Summary

Hydraulic actuators have an industry reputation for delivering high force. Hydraulic systems are usually less expensive from a purchased cost standpoint to implement than an electric servo system. Their drawbacks include a larger space footprint, regular maintenance and manual system adjustments for optimal system performance. Hydraulic systems are susceptible to fluctuations in temperature, prone to leaks and operate in an open loop environment, posing challenges for data collection. Although servo-hydraulics can be implemented to alleviate some of these issues, they result in a larger space footprint and are very costly to employ. Hydraulics do offer a long service life, but they are not as efficient operators as electric systems.

Electric systems offer smaller overall space requirements than hydraulic systems. They also provide precise position, velocity and speed control with more efficient operation. They operate in a closed loop environment for easy data collection, and they are virtually maintenance free. Preferred for their higher level of accurate performance, electric servo systems can be more costly than hydraulic to initially implement. However, the increased efficiency of operation with little or no maintenance over the life of the system makes their total cost of ownership lower over the life of the equipment and an attractive alternative to hydraulics.

As electric rod-style actuators become capable of achieving high-end hydraulic forces, they will continue to be viable candidates for replacing hydraulic systems in many applications.