High force linear actuator: electric replaces hydraulic

By Tolomatic on October 4, 2016

It used to be that when a machine designer was confronted with a high force linear actuator application, the only solution was a hydraulic cylinder. That meant the designer had to factor in the bulky hydraulic power unit (HPU), the inevitable leaks of hydraulic fluid and the downtime produced by frequent maintenance.

It used to be that when a machine designer was confronted with a high force linear actuator application, the only solution was a hydraulic cylinder. That meant the designer had to factor in the bulky hydraulic power unit (HPU), the inevitable leaks of hydraulic fluid and the downtime produced by frequent maintenance.

Now there’s another option when a high force linear actuator is needed. There are electric linear actuator products that can meet demanding specifications with ease.

Often, high force performance starts with the selection of the correct power screw/nut combination. Roller screws offer the best performance in both high force and long life, although ball screws deliver higher thrust than acme screws. Download our guide to screw selection for more information.

Sawmill needs a change

A sawmill needed a new linear actuator solution for moving a heavy saw blade used to cut logs. They had been using hydraulic cylinders because it took a lot of force to move the saw; however, the cylinders leaked fluid and contaminated the surrounding environment. The sawmill is located on a protected body of water, and contamination can incur hefty government fines.

Production is wet and dusty due to wood particles generated by sawing and water used to cool saw blades. Also, logs often strike equipment, and there are extreme temperature fluctuations.

The hydraulic cylinders stood up to the dirty environment and impacts but had trouble with temperature changes. Cold temperatures resulted in sluggish and inconsistent performance. Heat caused oil to degrade and seals to fail. The cylinders had significant maintenance requirements that caused equipment downtime, plus they had low accuracy and were difficult to adjust or change.

New high force linear actuator solution

The company wanted accuracy, repeatability, and programmability as well as the high force, environmentally-friendly, heavy duty attributes noted above. Their best solution was electric linear actuators.

The sawmill settled on the recommended IP67-rated RSA high force linear actuator because it could:

- Deliver the accuracy, speed and force required

- Eliminate hydraulic fluid as a source of environmental contamination

- Withstand dust, water spray, and impacts

- Increase the reliability of the sawing equipment and reduce maintenance

- Operate in low and high temperatures

- Be re-programmed quickly and easily for multiple motion profiles

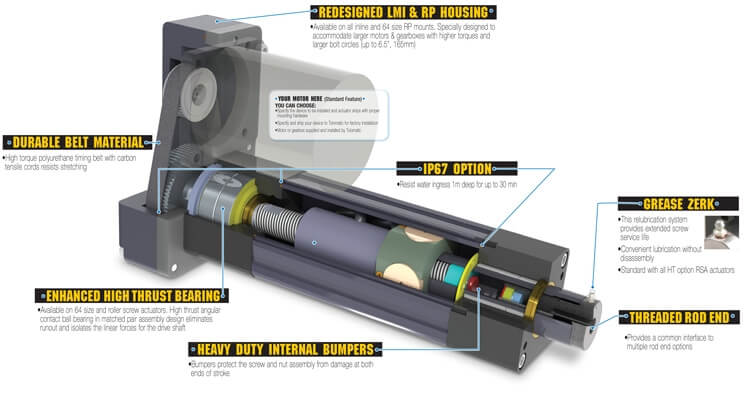

The RSA64 high force actuator’s heavy duty design can survive the sawmill’s rigors, even shocks and impacts. The IP67 selection seals the actuator against spraying water and wood dust. Special grease means the actuator can perform well in all temperatures. The RSA64 selected used a roller screw to deliver the required thrust.

RSA electric rod actuators

RSA electric rod actuators

RSA/RSM heavy duty linear actuators offer an extensive selection of sizes, options, and system components. RSA-HT models are capable of force up to 13,039 lbf or 58 kN. Designed with high force, heavy duty performance, and long-term reliability in mind, RSA/RSM high force linear actuators are a cost-competitive solution for many applications.

Click here for a catalog of the RSA/RSM family

Learn more

Download our guide: Which Screw? Picking the right technology.