IMA-S Stainless Steel Servo Motor Actuator

Hygienic servo actuators for the most demanding food and beverage applications

The IMA-S is a hygienically designed integrated electric servo actuator for the food and beverage processing industry. The IP69K rated design features a 316 stainless steel construction, hygienic fasteners and cord grips, ideal for effective cleaning.

- 2 body sizes with built-to-order stroke lengths and mounting options

- Forces up to 2,500 lbf (11.1 kN)

- Stroke lengths up to 18 inches (457 mm)

- Standard internal anti-rotate thrust rod option available

- IP69K standard protection against high pressure washdown

Find the right drive and cable connection to complete your system

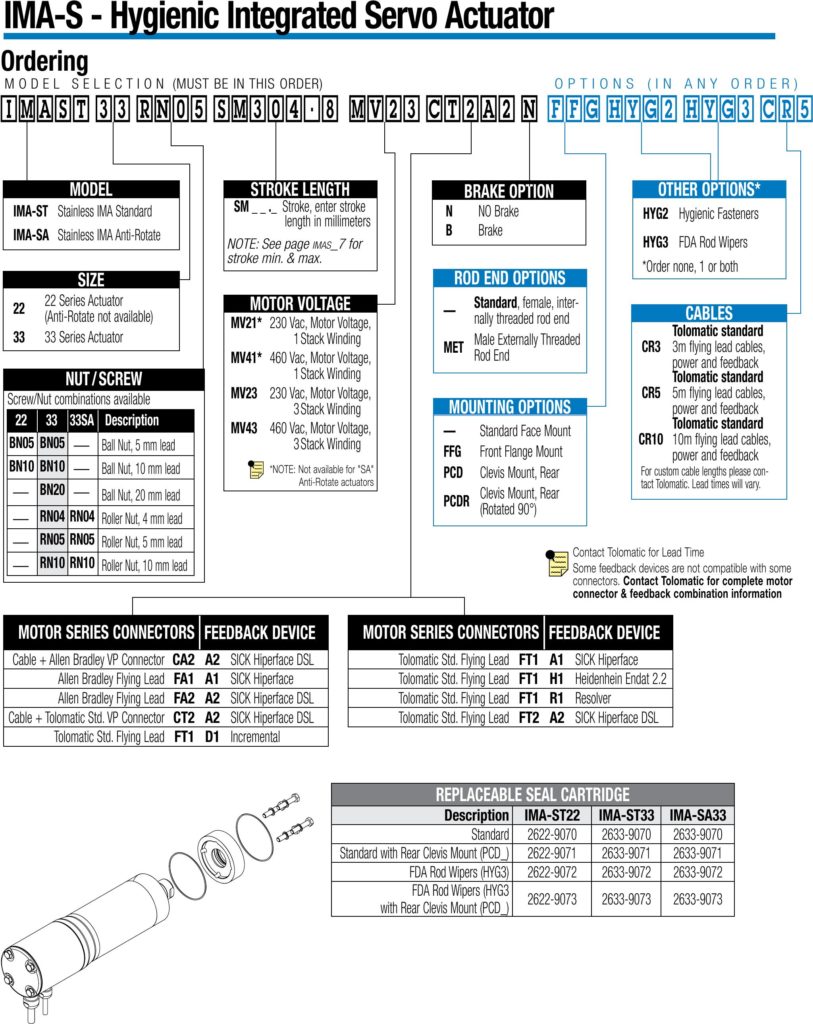

Features & Ordering

Download the IMA-S Brochure for full details on features

IMA-S: Hygienic Integrated Servo Actuator Features

IMA-S Features & Advantages

IMA-S: Hygienic Integrated Servo Actuator Features

The efficient, corrosion resistant 316 stainless steel design of the IMA-S hygienic integrated servo motor actuator is power dense, and features:

- Skewed winding to minimizing cogging torque for smooth, repeatable motion

- A low electric time constraint motor for quick response

- Welded, polished joints to create exceptionally hygienic seams

- Chemically inert, wear resistant blue gaskets and o-rings

- Flexible feedback and cable options including single (DSL) and dual cable

- An FDA-approved field replaceable seal cartridge that is IP69K rated for wash-down protection

IMA-S Ordering

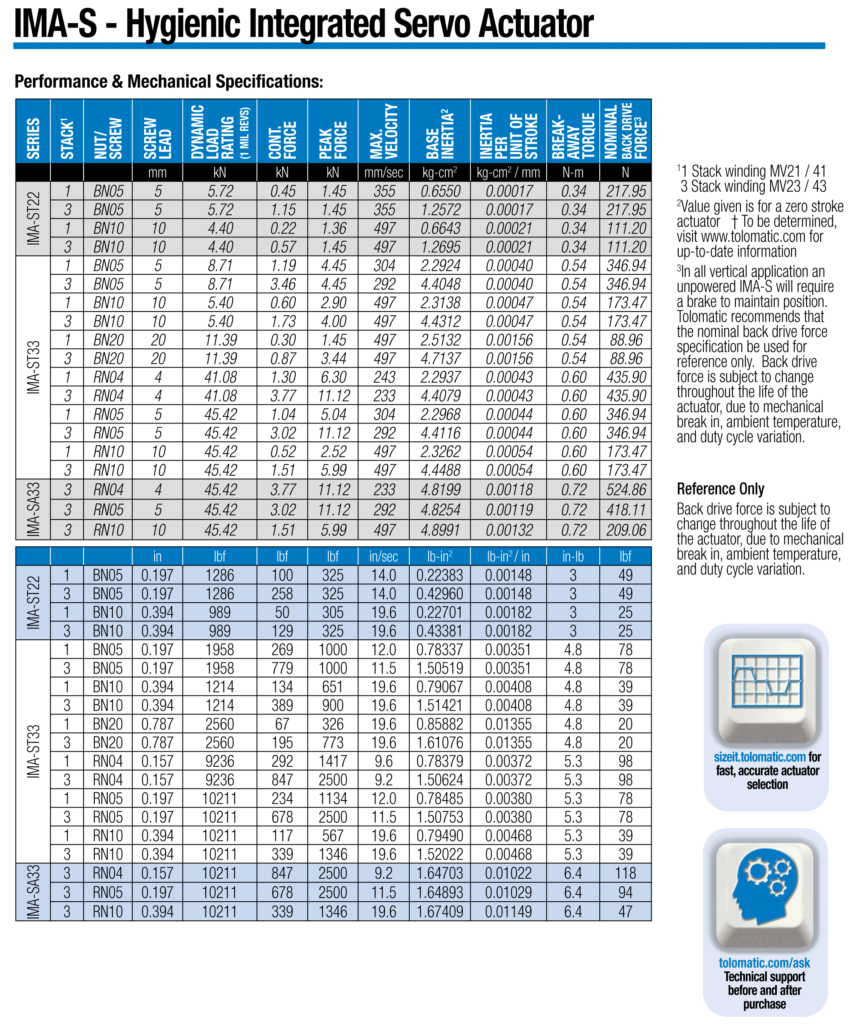

Specifications

| Specification | Units | IMAS22 | IMAS33 | IMAS33SA |

|---|---|---|---|---|

| Maximum Stroke | in (mm) | 12 (305) | 18 (457) | 12 (305) |

| Maximum Force | lbf (kN) | 325 (1.45) | 2,500 (11.1) | 2,500 (11.1) |

| Maximum Speed | in/sec (mm/sec) | 19.6 (500) | 19.6 (500) | 19.6 (500) |

IMA-S Performance Specifications

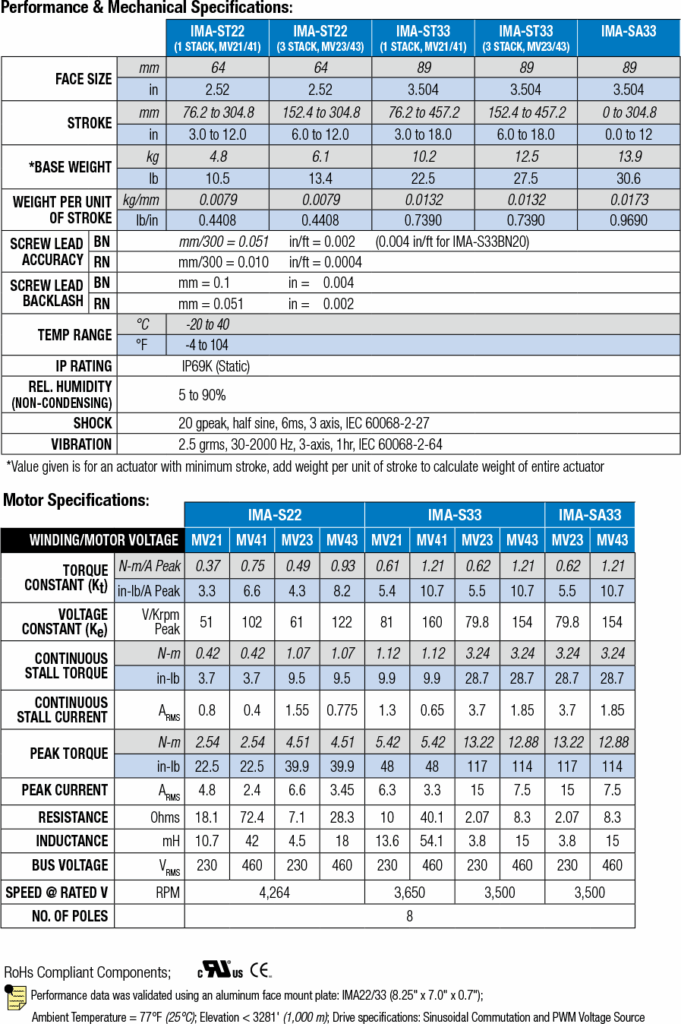

IMA-S Motor Specs & Additional Performance, Mechanical Specs

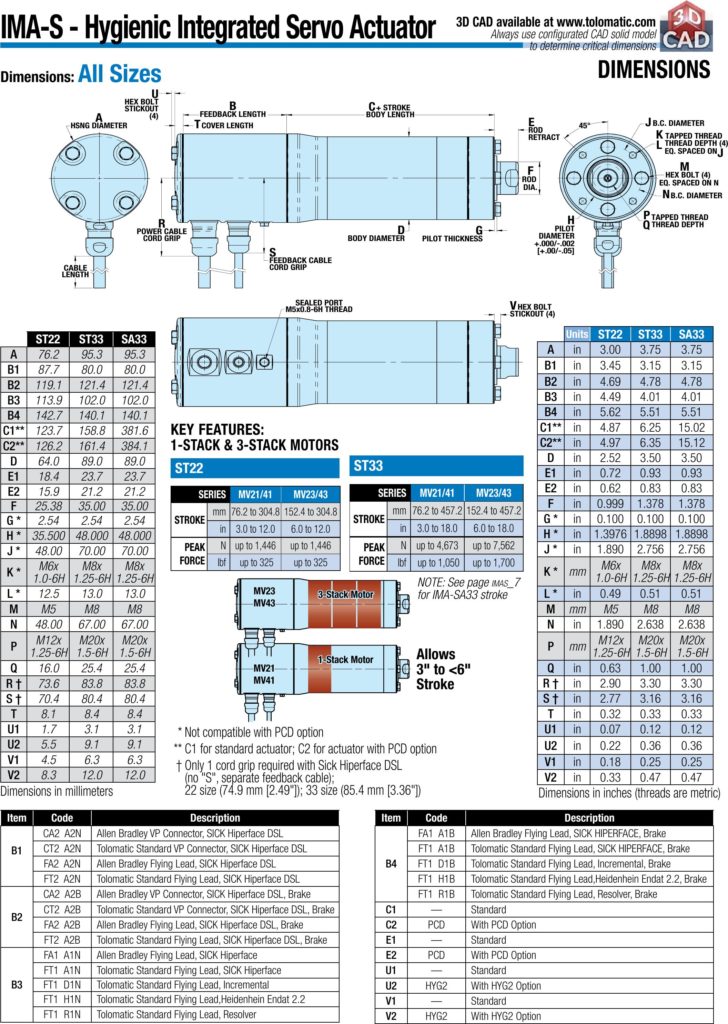

Dimensions

IMA-S Dimensions

Get CAD

Manuals & Part Sheets

Additional Resources

Information Center:

Application Checklists

Catalogs & Brochures

- Unternehmensübersicht (German, Corporate Overview brochure)

- 公司概述 (Chinese, Corporate Overview Brochure)

- Brochure sur l'entreprise Tolomatic (French, Corporate Overview-Linear Motion Solutions Brochure)

- IMA-S Hygienic Integrated Servo Actuator

- IMA-S Servoactuador Higienico Intergrado (IMA-S b, Spanish transl)

- 汽车行业应用手册 Brochure (Chinese: Automotive Applications Brochure)

- Soluciones para Alimentos y Bebidas (Spanish, Food & Beverage Solutions Brochure)

- Medical and Life Sciences brochure

- Electric Pressing Solutions Brochure

- OEM Actuator Solutions Brochure

Certifications

E-Books

Flyers

- IMA-S Hygienic Integrated Servo Actuator Flyer

- IMA-S Hygienic Integrated Servo Actuator, Integrated Servo Linear Actuator Flyer (German translation)

- IMA-S ACTUADOR CON MOTOR INTEGRADO DE ACERO INOXIDABLE (Spanish - IMA-S Stainless steel integrated motor/actuator)

- Revolutionize Volumetric Filler Performance

Guides

Software & Firmware

Terms & Conditions

Videos

White Papers

- Utilizzo degli attuatori elettrici nelle applicazioni di processo (WP: IT: Actuators for F&B processing applications)

- How roller-screw and ball-screw actuators compare in high-force applications

- Actuadores eléctricos con vástago frente a cilindros hidráulicos: una comparación de los pros y los contras de cada tecnología (Spanish - White paper - Electric vs Hydraulic Actuators)

- Top 5 best practices for designing electric actuators into food processing equipment

- Elektrische Antriebe und Pneumatikzylinder: Ein Vergleich basierend auf den Gesamtbetriebskosten weißes Papier (GERMAN, TCO WhitePaper)

- Designing Gantry and Multi-Axis Automation Systems

- Diez Consejos Óptimos: Cómo especificar los actuadores eléctricos de vástago para obtener rendimiento, confiabilidad y eficiencia óptimos

- Comparación de la tecnología de los actuadores eléctricos: Diseños integrados y tradicionales

- Medical Device Motion Design Considerations

- Integrierte und traditionelle Bauweisen Weißbuch (DE, Integrated and traditional designs WP)

- Unleashing the Capabilities of the Linear Servo Press in Manufacturing

- Liberar las Capacidades de la Servoprensa Lineal en la Fabricación

- Making the Jump to Electric

- How Integrated Linear Actuators Simplify Design and Elevate Performance

- TOP 10 TIPPS: So spezifizieren Sie elektrische Stellantriebe in StabformAktuatoren für optimale Leistung, Zuverlässigkeit und Effizienz (How2specify^DE)

- TOP 10 TIPPS: So spezifizieren Sie elektrische Stellantriebe in StabformAktuatoren für optimale Leistung, Zuverlässigkeit und Effizienz (How2specify^DE)

- Understanding Servo Linear Actuator Systems

Success Stories

Additional IMA-S information

The IMA-S is a hygienically designed integrated electric servo actuator for the food and beverage processing industry. The IP69K rated design features all 316 stainless steel construction, hygienic fasteners and cord grips, ideal for effective cleaning.

Drive Integration

Tolomatic’s integrated motor products (IMA & IMAS) integrate with a wide range manufacturers’ servo drives. Check our Drive Integration Resource for supporting documentation and motor files.

Tolomatic supports integration with Rockwell Automation through the use of custom motor files (CMF). See our Tech Note: interfacing the IMA actuator and absolute encoder with Rockwell Automation servo drives.

Flexible design with options to fit your application

This product line includes an option for an internal anti-rotate feature eliminating the need for an external guidance mechanism, ideal for applications such as volumetric filling and pumping.

Feedback options include multi-turn absolute encoders (Hiperface DSL, Hiperface Sin-Cos, EnDat 2.2), incremental encoder, and a resolver to integrate with most PLC or control systems.

Improve hygienic machine design with IMA-S food grade integrated servo motor actuators

- Provides complete control over speed and position at all times

- Hygienic design to allow for food grade cleaning and sanitizing

- Resists corrosion with 316 stainless steel body

- Provides IP69k wash-down protection with blue seals/o-rings and hygienic fasteners/cord grips

- Improves performance, flexibility and efficiency in comparison to fluid power technologies

Ask an Engineer

Ask an Engineer