Solid-bearing, belt-driven linear actuator handles harsh environment

By Tolomatic on July 26, 2016

Many applications call for the carrying action of a rodless electromechanical actuator. And many of these need the high speed and long stroke capabilities of a belt-driven linear actuator. But what do you do when your application is in a dusty, harsh environment? Many rodless electromechanical actuators can’t handle these conditions. Their roller bearings get clogged with dust and stop working. Could a solid bearing be the solution?

Many applications call for the carrying action of a rodless electromechanical actuator. And many of these need the high speed and long stroke capabilities of a belt-driven linear actuator. But what do you do when your application is in a dusty, harsh environment? Many rodless electromechanical actuators can’t handle these conditions. Their roller bearings get clogged with dust and stop working. Could a solid bearing be the solution?

When you need general advice on specifying rodless electromechanical linear actuators, look to Tolomatic. Our 10 tips white paper provides the information you need. Download it here.

Read further to learn how one user solved the problem of handling a harsh environment with a rodless actuator.

Harsh environment causes problems

Paper making creates tough environmental conditions for automation equipment. Water, chemicals and wood dust combine to challenge machinery.  Designers who work for this industry have to take these factors into account in order to develop long-lasting, hard-working production systems.

Designers who work for this industry have to take these factors into account in order to develop long-lasting, hard-working production systems.

We recently worked with the designer of a paper processing machine to develop a new roller-cleaning mechanism. In earlier machines, pneumatic rodless actuators powered the brushes that cleaned pulp from the paper-making machine’s rollers. These actuators failed frequently because pulp particles caused seal failures. The on-going maintenance the pneumatic actuators needed was very costly.

The machine designer wanted to use an electromechanical actuator to avoid the problem of seal failures in pneumatic actuators. The application had a stroke length of over 100 inches (2540mm), making a belt-driven actuator the best choice. However, many of the belt-driven electromechanical actuators that were considered had roller bearings on their carriers. Pulp particles got into the roller bearings, clogging them and leading to actuator failure.

Solid bearing is the solution

The machine designer worked with Tolomatic to find a solution – our new MXB-S electric belt-driven linear actuator. The MXB-S with its unique solid bearing replaces the previously-used pneumatic actuator that was causing failures and high maintenance costs. This new rodless actuator’s solid bearing is self-cleaning. It easily pushes pulp away as it moves the carrier back and forth on the actuator body. The end of the actuator is left open so moisture and pulp particles can be pushed out. A stainless steel gearbox and motor power the actuator. Stainless steel was selected to withstand the wet environment.

The machine designer worked with Tolomatic to find a solution – our new MXB-S electric belt-driven linear actuator. The MXB-S with its unique solid bearing replaces the previously-used pneumatic actuator that was causing failures and high maintenance costs. This new rodless actuator’s solid bearing is self-cleaning. It easily pushes pulp away as it moves the carrier back and forth on the actuator body. The end of the actuator is left open so moisture and pulp particles can be pushed out. A stainless steel gearbox and motor power the actuator. Stainless steel was selected to withstand the wet environment.

The MXB-S delivers reliable performance and increased actuator life in this application. Plus, there’s less downtime, and maintenance costs are lower.

Introducing the new MXB-S

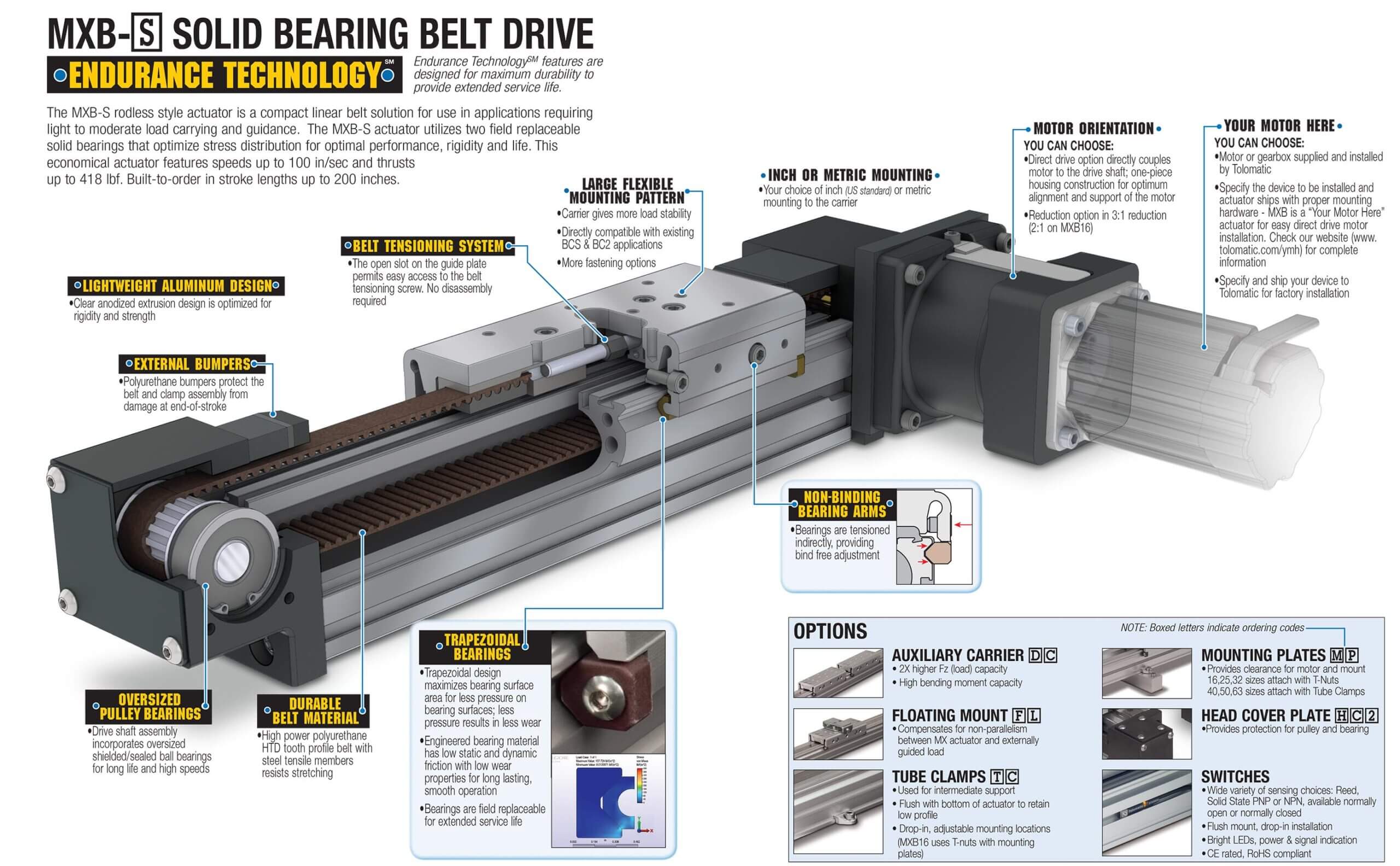

The MXB-S belt-driven linear actuator is the newest member of the MXB rodless electromechanical actuator series. The series includes the MXB-U unguided belt-driven linear actuator and the MXB-P heavy duty linear actuator with profiled rail carrier bearings. The MXB-S features a trapezoidal, self-cleaning solid bearing system for the carrier, a bearing system that is field-replaceable.

The MXB-S is a good choice for applications in harsh environments like paper production or sawmills because of its long-lasting, self-cleaning bearing. It is also  well-suited to applications requiring light to moderate load carrying and guidance. This low-cost linear actuator offers speeds of up to 100 in/sec (2540 mm/sec) and thrusts of up to 418 lbf (1860 N). The MXB-S is a long stroke linear actuator that is available in stroke lengths of up to 200 inches (5080 mm).

well-suited to applications requiring light to moderate load carrying and guidance. This low-cost linear actuator offers speeds of up to 100 in/sec (2540 mm/sec) and thrusts of up to 418 lbf (1860 N). The MXB-S is a long stroke linear actuator that is available in stroke lengths of up to 200 inches (5080 mm).

Download the MXB catalog here.

For more information

To learn about specifying rodless electromechanical linear actuators, download our 10 tips white paper.