Electric Actuators Help You Keep Up With the NFPA Technology Roadmap

By John Fenske on September 3, 2025

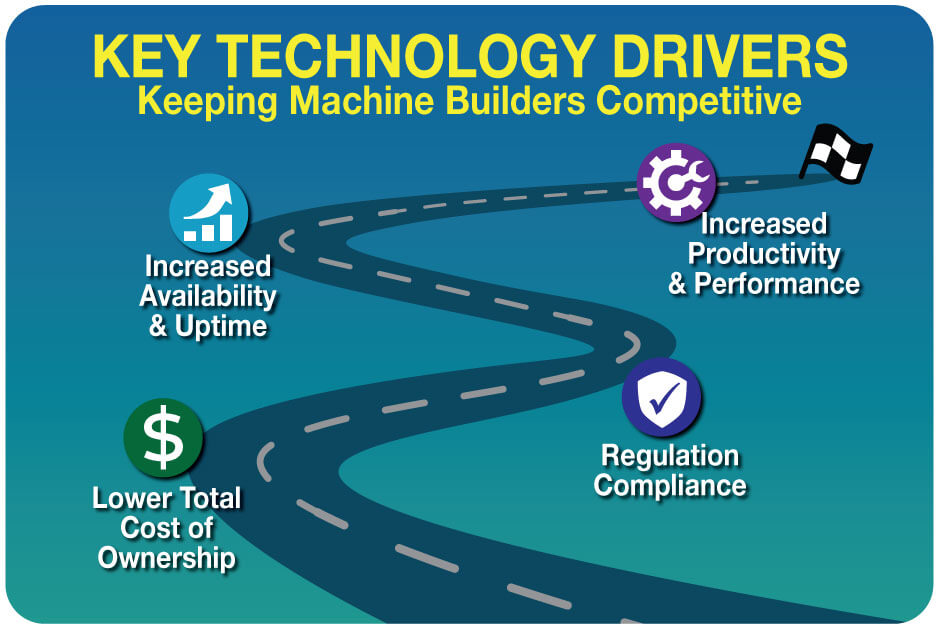

A recent National Fluid Power Association (NFPA) survey illuminated technology objectives that enable machine builders and OEMs to stay competitive in their industries. The most important objectives that emerged from the survey included:

- Increased availability and uptime

- Increased productivity and performance

- Regulation compliance

- Lower total cost of ownership

While well-designed fluid power systems may support these objectives, it’s interesting to point out the easiest path toward meeting these goals may be to use electric actuation instead of fluid power. Here’s why electrification matters:

Increasing Uptime and Availability

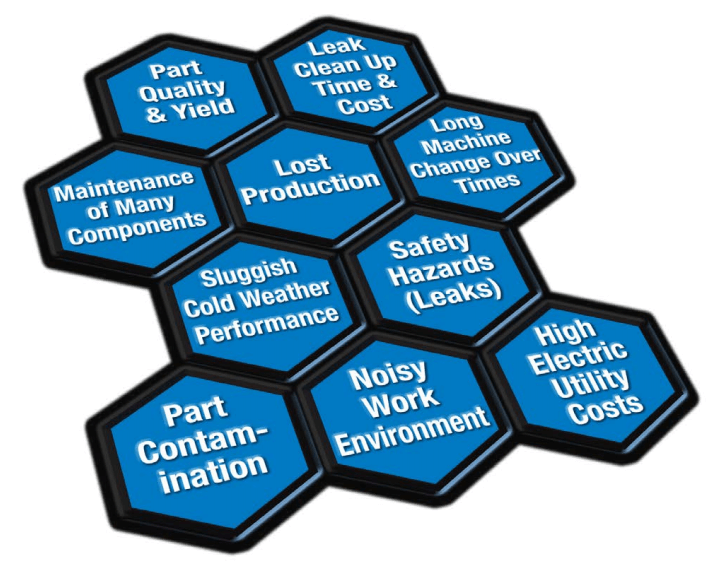

Electric linear actuators are an excellent choice to increase a machine’s availability and uptime because of their high reliability and performance while requiring very little maintenance. One factor that contributes to their reliability is that electric linear actuators generally feature fewer components than hydraulic or pneumatic actuators. Without components like hoses, valves, filters and fittings, electric linear actuators eliminate many sources of breakdowns and routine maintenance.

Avoiding the use of seals provides an additional boost to machine uptime by increasing the predictability of an electric actuator’s lifespan. Seals used in hydraulics and pneumatics that contribute to power transmission can degrade over time, leading to performance loss and eventual failure if not routinely inspected, maintained and replaced. But with electric linear actuators, predicting lifespan is a simple calculation.

Like the workhorses of pneumatic and hydraulic cylinders, electric linear actuators feature durable designs that withstand rugged industrial environments.

Environmental protection is especially apparent in an integrated actuator, which couples the servo motor and actuator within the same housing. Not only does this design prevent ingress from dust, debris and moisture, it also provides increased rigidity and resistance to shocks and vibrations. The durability of electric actuators make them excellent choices when designing machines to maintain smooth, uninterrupted production.

Unlike hydraulics, electric actuators are generally unaffected by temperature fluctuations. Without requiring heated or cooled oil, electric actuators maintain consistent performance across temperature ranges. And because these actuators don’t use filters or fluids that need regular changing, a properly sized actuator for an application will require little to no maintenance throughout its life.

Increasing Performance and Productivity

A major advantage of electric actuators over hydraulic cylinders is that they have greater motion control flexibility for:

- Position

- Velocity

- Acceleration

- Force

Electric actuators deliver complex, real-time control of all of these motion variables. Coupling a servo drive and motor system unlocks accuracy and repeatability far greater than hydraulics can offer.

Because servo systems constantly monitor the electric actuator’s torque, they can deliver consistent forces often within single digit percentages with no manual maintenance or adjustments. These actuators also offer closed loop control without external sensors, allowing for multiple positions in the motion profile with quick and highly repeatable settling times. With such fine degrees of control, electric actuators often optimize many production processes.

While hydraulics have excellent thrust capability, it is also possible to achieve similarly extreme forces with electric actuation. In fact, electric linear actuators are excellent options in high-force applications because they offer high continuous force capacity in a very small package.

Tolomatic even offers an easy-to-use sizing software, SizeIt, that takes the guesswork out of specifying an electric actuator. Simply input your application requirements like force, stroke and lifespan.

These actuators also easily support programmable motion profiles to adjust forces, speeds and strokes. With this level of control, machines built with electric actuators can deliver performance tailored to a wide range of specialized applications.

Hydraulics require complex, expensive servo-hydraulic systems or external sensors to track position, velocity, force and other motion control factors. However, electric actuators already have this capability, which facilitates easy data collection for analytics and condition monitoring. Analyzing gathered data allows for process optimization that can increase productivity and performance.

Reducing moving mass is a common avenue for engineers to improve machine performance. This is an excellent use for an integrated servo linear actuator because they consolidate both a servo motor and actuator into one package. This design cuts the overall weight of the full actuator system, enhancing motion efficiency as well as maintaining a center of gravity that is aligned along the center axis.

Complying With Regulations

It is impossible to completely eliminate the potential for fluid leaks when using hydraulic actuators. Hydraulic fluid spills are a safety hazard. Personnel can slip and be injured, and leaking fluid can also contaminate processes and products. This is especially problematic in industries like food, pharmaceutical, medical device and semiconductor manufacturing. Eliminating the potential for hydraulic fluid contamination avoids the costs associated with cleanup, product losses and recalls.

Many industries are striving to meet objectives that minimize environmental impact. Implementing hydraulic technologies makes it a challenge to achieve these goals because of their potential to leak fluid. On the other hand, electric actuators are a natural choice. Electric actuator technology is one of the cleanest linear motion technologies. The only potential contaminant is the grease on the lead screw, and special greases like food-grade and cleanroom grease can be used instead if necessary. Electric actuator rods feature high-quality seals that virtually eliminate any risk of contamination.

Regulations related to hygiene are also common in industries where the risk of contamination is especially impactful. In addition to eliminating leaks, it’s important to design machines with hygienically compliant components. Electric actuators are a good option because they can be designed to meet food safety regulations such as stainless steel construction and withstanding washdowns. Hydraulic and pneumatic cylinders can be designed for food-safe construction, but the potential for leaks and filtration requirements decreases their feasibility as hygienic components.

When selecting an electric actuator for hygiene requirements, consider these factors:

- Housing materials

- Seal materials

- Easy-to-clean designs

- Operating temperatures

- Ingress protection

Industries like medical device, pharmaceutical, automotive and aerospace manufacturing require machines that comply with stringent performance and safety regulations. Both traditional and integrated actuators will often feature built-in safety features like holding brakes. The holding brake can arrest the rotor in case of a power loss and prevent catastrophic damage — an especially important feature in vertical applications. Certain environments may have regulations to limit noise, and electric actuators generally operate much more quietly than similarly sized pneumatic cylinders.

A significant advantage of electric actuators is their controllable precision. These actuators are frequently used in advanced, precision applications like aerospace and semiconductor manufacturing because servo feedback enables fine-tuned control to adjust processes and hone in exact motion profiles to meet high tolerance requirements.

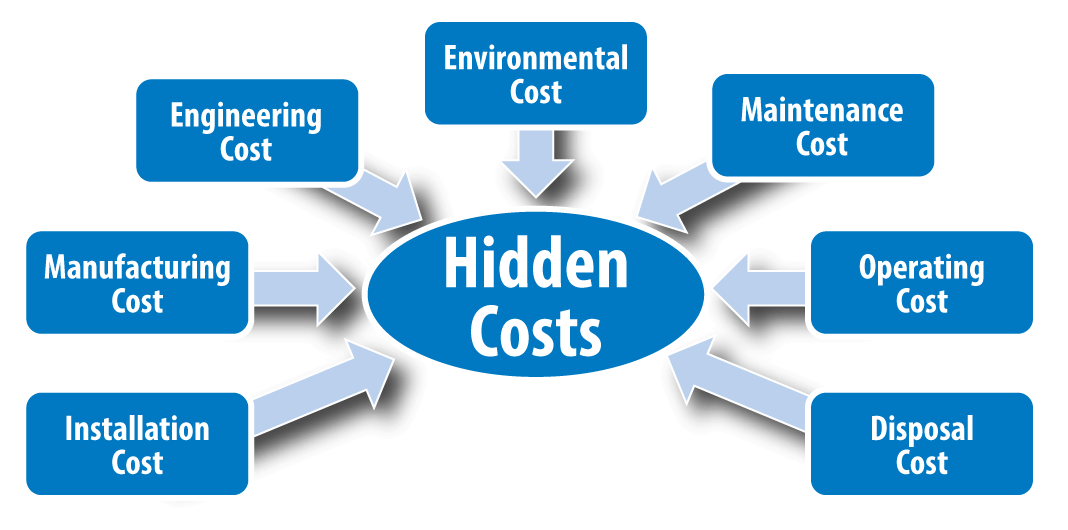

Lowering Total Cost of Ownership

When converting to electric actuation from hydraulic, it is important to properly size an electric actuator based on the work previously applied by the hydraulic cylinder. The work applied by a hydraulic cylinder is a function of the pressure within, and when using the maximum-rated pressure of a hydraulic system to specify an electric actuator, it can lead to an oversized system.

Oversizing a hydraulic cylinder often leads only to a marginal increase in cost, but electric actuators can feature significant cost increases with increasing force. Electric actuators remain a cost-effective alternative compared to hydraulics, but keep in mind that cost benefits can be discarded when specifying an electric actuator with a safety margin far beyond what is necessary.

To prevent oversizing an electric actuator, don’t oversimplify the force calculations. Instead, determine the true peak and continuous working force of the hydraulic cylinder. The best method is to obtain exact pressure readings during operation. If this is impossible, estimations within 15% are reasonable enough.

Electric linear actuators lower overall costs of a machine because they do not use the consumable materials required in pneumatic and hydraulic cylinders. Routinely replacing materials like fluid or seals contribute to the overall costs of hydraulics and pneumatics as well as time spent on maintenance. It is necessary to replace these materials in order to maintain performance, which can decrease as seals wear down.

Efficiency is another advantage of electric actuators, which feature significantly lower utility costs. Hydraulic cylinders will typically operate with 40 to 55% efficiency for the work they complete, compared to the 75 to 80% efficiency of electric actuators. Additionally, electric actuators only require power while the motor operates. Very little or no current flows when the actuator holds position. Hydraulics require power at all times to pressurize the cylinder.

While servo-hydraulic systems feature increased efficiency compared to standard hydraulics, they do not match electric technologies. As an approximation, electric actuation can be considered twice as efficient as hydraulics. Servo electric systems may initially cost more than hydraulics, but long-term lower utility costs provide significant benefit.

Another avenue to reduce total cost of ownership is an integrated actuator. Integrated designs cut down on integration time and cost because they eliminate the hassle of specifying and mounting a motor.

The NFPA technology roadmap is scheduled to be published near the end of 2025. Until then, read more about electric actuators in our white paper.

Ask an Engineer

Ask an Engineer