Machine builders: Have it your way

By Matt Gulleen on May 4, 2021

Modified and custom actuators are another tool in your actuator design toolbox.

You need epoxy coating with that? How about a different type of belt? Longer stroke length? Reverse parallel? It’s usually straightforward to tweak a feature on a catalog product into something we call a modified standard product. These relatively simple and cost-effective modifications may include custom extrusion length, various belts, a whole range of protective features, stainless steel constructions, and much more. Tolomatic’s capabilities don’t just stop at simple modifications either. Sometimes, you may need a highly customized solution for a specific application. We call these more complex modifications a custom product. Designing a custom product is a more involved process, but we’ve seen some amazing actuators come out these opportunities. Many custom products are now standard catalog offerings. It all depends on your application and how the actuator is used in it.

Modified standard

We define a modified standard product as a catalog product with a small number of features changed or added to fit a specific requirement. Modifications range from simple to complex. For example, the rodless belt-drive actuator shown on the right was modified so that a purge port was placed in a specific location on the extrusion. That’s a simple modification. The actuator was also coated in blue epoxy so it would perform reliably in a heavy duty environment. That’s a comparatively complex modification due to the number of parts that must be coated individually prior to assembly.

Other common modifications include:

Custom motor mounts

- Tolomatic’s extensive database (“Your Motor Here”) makes it easy to match your motor of choice with the correct mounting assembly. The actuator ships with the correct mounting plates and couplers. However, sometimes a unique type of motor isn’t in the database. This can be solved relatively quickly with a custom motor mount.

Special motor couplings

- Correctly couple the motor shaft to the screw or pulley. Common requests include spider couplers , servo couplers, and keyed couplers (shown).

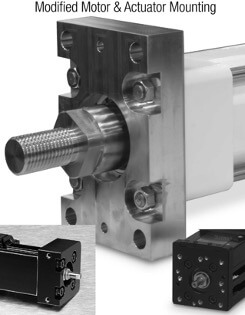

Actuator mounting feature change

- Sometimes an actuator mount requires a different hole pattern or thread size.

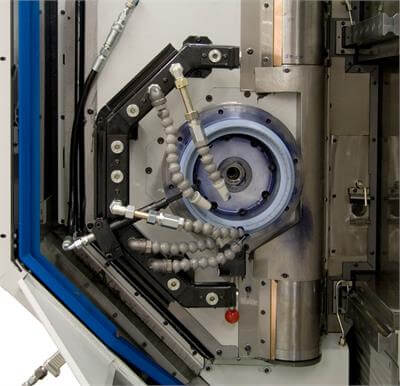

Modifying a catalog product: Moving a manifold of cooling jets

Here’s an example of how we modified a catalog product.

In a machine tool builder’s gear grinding system, a flow of lubricating coolant needs to be precisely directed at the grinding wheel’s point of contact at all times to ensure the best finish. In the original cooing head design, an electric actuator moved a 50-pound manifold of coolant jets in small increments as the grinding wheel was consumed and changed dimensions. However, the actuator sometimes had trouble moving the heavy manifold. The added friction caused the coolant head to lose position, which stopped the machine.

A new actuator needed to handle the manifold, fit in the limited space and withstand the wet environment. An RSA electric rod actuator with reverse-parallel motor drive (the motor is mounted alongside the actuator) saved space while also meeting the force requirement. To operate in the wet environment, the actuator was modified with sealing gaskets and a front flange to prevent ingress of fluids. With relatively simple modifications, the actuator eliminated machine faults and helped the manufacturer increase productivity and reliability.

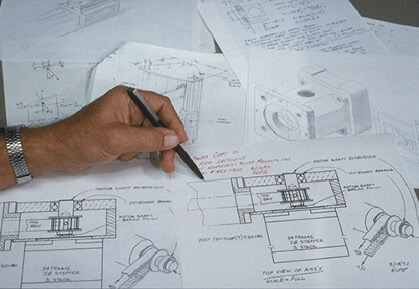

Custom product: Starting from scratch

We define a custom product as a solution that starts with a blank sheet of paper. These are products you won’t see in a catalog, and can be very successful in special applications. It takes teamwork between you and Tolomatic to ensure the appropriate application requirements, and we have had some notable successes. Sometimes custom products also become standard products. For example, Tolomatic’s ServoWeld actuator started as a custom product. So did the IMA stainless steel actuator, the ERD and the TRS.

Custom product application: Aligning the color registry on a large-scale commercial printing press

Here’s an example of how we developed a belt-driven actuator to meet a specific requirement:

A printing press manufacturer’s existing press design used a low-profile and economical belt-driven actuator to move and position a camera that monitors the color registration process. Low-profile and economical were both desirable features. However, the actuator’s internal components were exposed, and fine dust particulate generated from paper residue settled into the bearing system. This required frequent rebuilding, not to mention slowing the press. The customer needed new actuators as a drop-in solution.

Tolomatic developed a custom belt-drive actuator for the color registry system on the press. The actuator’s sealed internal roller bearings and dust band effectively protect against the ingress of dust particulates, while providing the required operating parameters: 120-inch stroke length, 4 inches/second speed and three pounds of load, and 50 inches/pound in the Mx.

As a result, the long-lasting actuator with enclosed design reduced downtime and maintenance costs.

Need to modify a catalog product or create something from scratch? Discuss your application with us and Start the design process.

Ask an Engineer

Ask an Engineer