Test your motion control smarts. Take the electric linear actuator quiz.

By Tolomatic on October 17, 2017

Linear actuators are common and critical elements in many industrial machines and automation systems. With so many choices on the market, it’s important to know how to select the best one for your application.

Linear actuators are common and critical elements in many industrial machines and automation systems. With so many choices on the market, it’s important to know how to select the best one for your application.

What type of linear actuator?

The decision of whether to use electric, pneumatic or hydraulic power is crucial for machine designers when specifying a linear actuator. A pneumatic cylinder can be easy to use and low cost, but compressed air leaks can make it inefficient. A hydraulic cylinder can provide high-thrust capabilities but will be sensitive to high/low temperatures and prone to messy, harmful fluid leaks.

An electric linear actuator can deliver high force without temperature sensitivity or leaks as well as offer these distinct benefits:

- Better performance — Electric linear actuators outperform fluid power technologies with better accuracy and repeatability, as well as precise control of speed, acceleration, deceleration and force. They offer infinite positioning and data collection capabilities, and can handle complex motion profiles.

Also, an electric actuator’s programming can be changed. If parameters evolve, the actuator can be adjusted to meet new specifications with minimal downtime and loss of productivity.

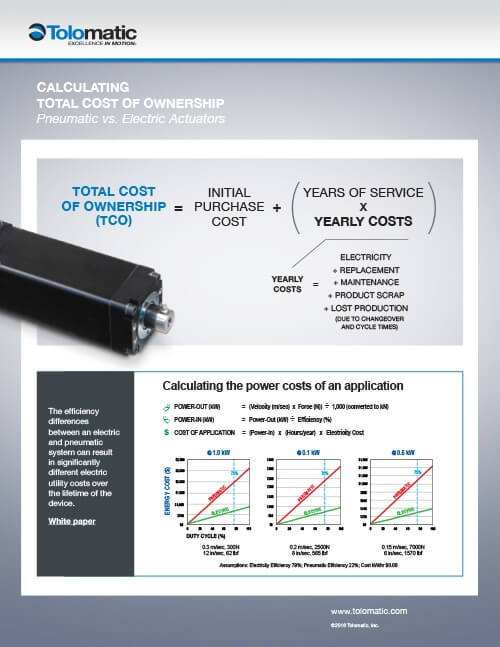

- Lower lifetime cost — Cost is an important consideration when selecting any equipment. Many design engineers look beyond initial purchase price to consider the device’s total cost of ownership (TCO). Total cost of ownership includes purchase price plus ongoing operating costs, like power, maintenance and downtime.

Because electric-powered linear actuator systems operate at 70-80% total system efficiency, compared to 40-55% for hydraulic and 10-15% for pneumatic systems, savings over an actuator’s service life can far outweigh the initial acquisition cost. Plus, electric actuators, when sized correctly, can last longer and require much less maintenance that fluid-powered cylinders.

Selecting the right electric linear actuator

Once you’ve decided on an electric linear actuator, some basic issues come up. Like deciding if a rod style or rodless linear actuator is the best choice. When you know which type fits your application, use these tips to fine tune your selection.

Selection tips

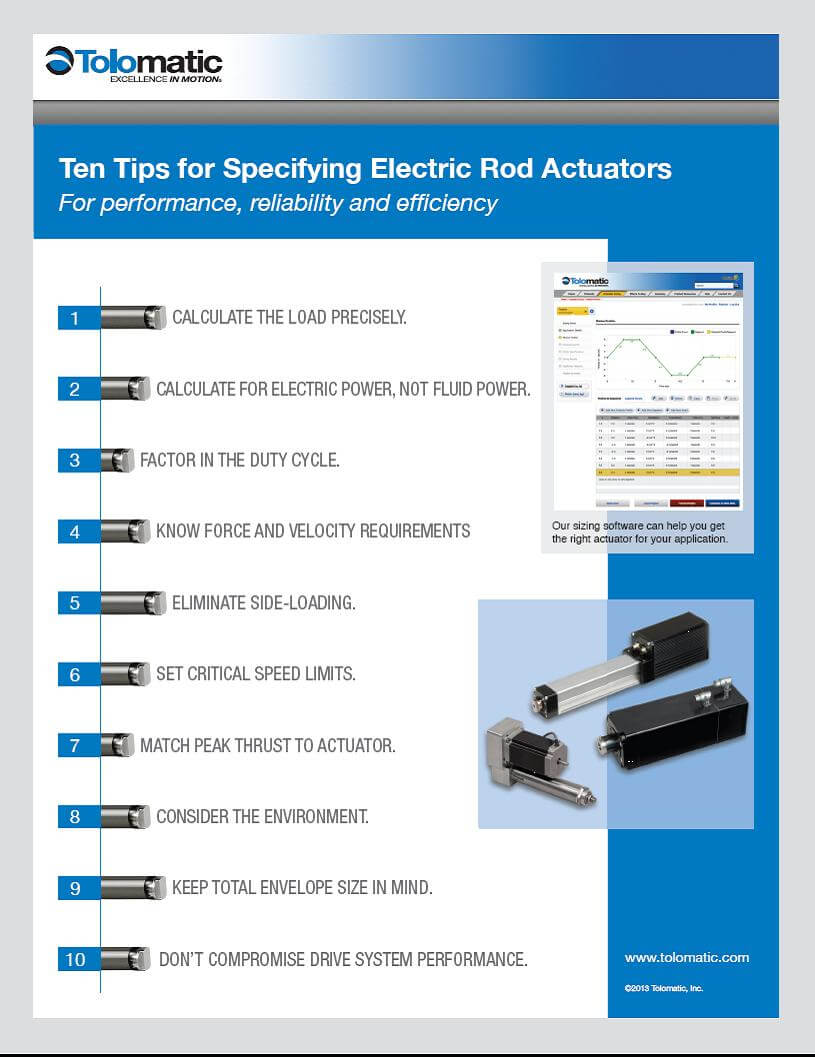

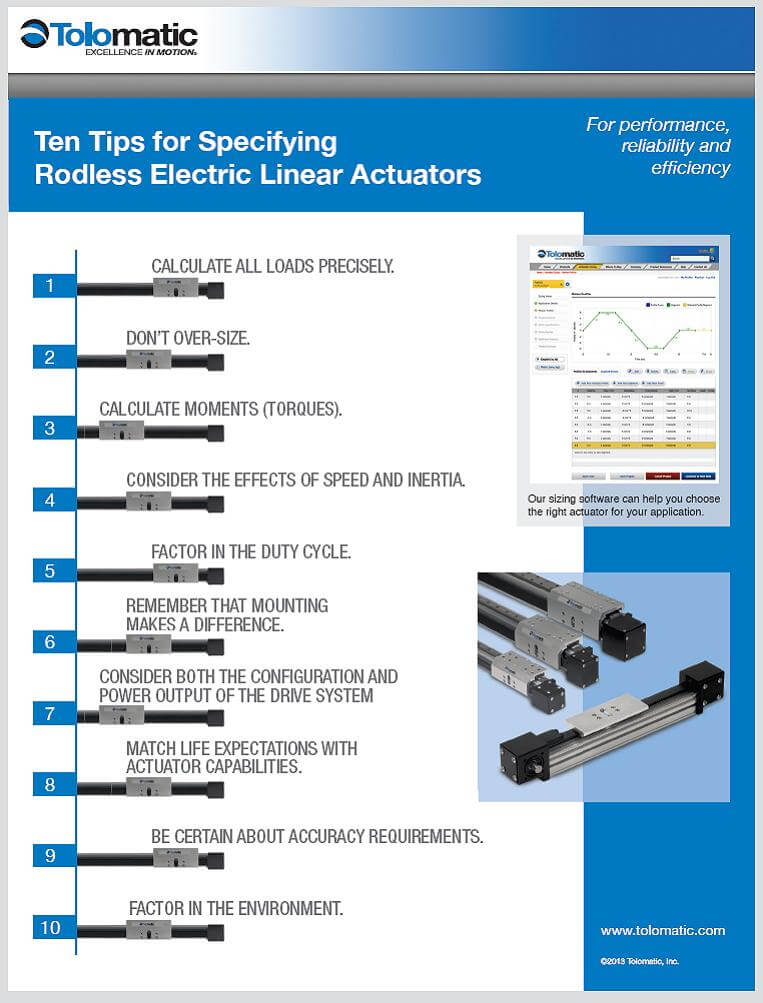

- Calculate size for electric, rather than fluid power– Don’t fall into the common fluid power practice of oversizing. Take advantage of sizing software offered by manufacturers to get the right size electric linear actuator for your application.

- Calculate loads precisely If you know the weight and size of the load, how far it needs to travel, and how fast it needs to move, you can accurately specify actuator components.

- Factor in the duty cycle That’s the ratio of operating time to resting time expressed as a percentage.

- Set critical speed limits Screw-driven linear actuators have lead screws with critical speed limits. If a screw has to operate at or beyond the limit, it will oscillate, causing noise, vibration and poor performance

- Factor in the environment Extreme heat and cold, moisture, dust or corrosive agents can cause problems. Washdown environments call for special materials and design considerations.

- Consider more than just the drive’s footprint Reverse parallel motor mounting saves space, but these configurations can be less powerful and efficient. Often only an inline motor configuration can deliver the speed and thrust required.

- Match life expectation to actuator capabilities If application requirements exceed the actuator’s capabilities, the actuator will die an early death.

Special tips for electric rod actuators

Because an electric rod actuator pushes or pulls its load, there can be deflection stress on the rod if the load isn’t properly aligned. Here are two special tips for specifying this type of actuator.

- Avoid side loading Electric rod actuators are prone to damage and wear when they have to deal with side loads. These actuators do not support the load as the rod extends.

- Know total envelope size Remember that the rod extends outside the actuator body. Avoid fit problems by knowing both the overall length of the electric actuator and its working stroke length.

Special tips for rodless electromechanical actuators

Special tips for rodless electromechanical actuators

Because a rodless electromechanical actuator carries the load, it’s subject to different stresses than its rod-style counterparts. Here are two tips for specifying rodless actuators.

- Calculate moments (torques) You can only specify the right actuator for an application if you’ve calculated roll, yaw and pitch on the actuator’s carrier.

- Mounting makes a difference If you need a long-stroke rodless linear actuator, make sure you factor in enough support points to ensure rigidity. The mounting surface must be straight and flat.

Learn more

You probably know a lot about linear actuators. But do you know everything? Our electric linear actuator quiz will test your engineering smarts.

Interested in electric linear motion? Join the discussion at our LinkedIn group.

Ask an Engineer

Ask an Engineer