Total cost of ownership: pneumatic vs electric linear actuators

By Tolomatic on July 25, 2017

Who doesn’t like to save money? We’re all in search of a good deal, but how do you define what’s good? If you buy something on the cheap but it falls apart in a short time, is that a good deal? Maybe it’s smarter to pay more for something that lasts longer and performs better.

Who doesn’t like to save money? We’re all in search of a good deal, but how do you define what’s good? If you buy something on the cheap but it falls apart in a short time, is that a good deal? Maybe it’s smarter to pay more for something that lasts longer and performs better.

In business, this means considering total cost of ownership (TCO), that is, initial acquisition cost plus operating costs. Comparing TCO to purchase price alone is especially interesting when applied to pneumatic cylinders and electric linear actuators. Although pneumatic cylinders often cost less at initial purchase, you may be surprised what wins the TCO prize.

View our webinar for the full story, or download our white paper. We also offer an infographic as a visual reference.

What is total cost of ownership?

Let’s be clear about what TCO is.

Total cost of ownership =

initial purchase cost +

[years of service X yearly operating cost (YOC)*]

*YOC (Yearly operating cost) =

replacement cost

+ maintenance

+ electric utility costs

+ product scrap

+ lost production due to changeover and cycle times

While utility costs, parts, and replacement are easy to quantify, labor costs, the cost of downtime, and costs associated with fluctuations in quality may be harder to determine.

TCO comparison: pneumatic vs electric linear actuators

1. Initial cost

Pneumatic cylinders win here. Most of the time a pneumatic cylinder for a given application will cost less than its electric competitor.

2. Service life

How long an actuator will last in an application depends on duty cycle. (Duty cycle is a ratio of an actuator’s operating time to its resting time. Duty cycle is expressed as a percentage. For example, an actuator that moves for two seconds and stops for two seconds has a duty cycle of 50 percent.)

Electric actuators with ball or roller screws have the advantage here.The service life of an electric actuator can be calculated by using the L10 life formula for estimating the life of rolling elements. This formula allows you to select and size an actuator that will last a long time in the application.

Engineers must rely on experience to guess at how long a pneumatic cylinder will last. High duty cycle applications can be hard on pneumatic cylinders.Seals wear out, compromising performance and prompting replacement.

3. Yearly operating costs

The factors in an actuator’s yearly operating costs vary by application, but here are some basics:

- Replacement

Some applications may wear out a pneumatic cylinder in just a few months.Replacement cylinders need to be purchased, and there are labor costs and system downtime expenses to consider.

Electric actuators, when sized correctly, have a very long service life, so there’s no need for frequent replacement.

- Maintenance

The seals on pneumatic cylinders are crucial since they hold in air pressure, but they wear and must be replaced. Also, pneumatic cylinders require regular lubrication. This all entails downtime, material, and labor costs. Seal wear and re-lubrication aren’t issues with electric actuators. In fact, electric linear actuators often require no maintenance at all.

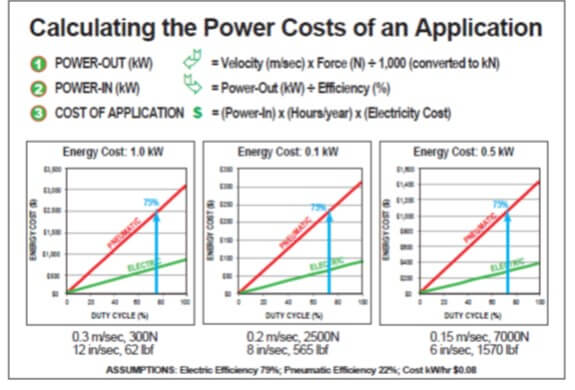

- Electric utility costs

The discussion of ele ctricity costs starts with efficiency, that is, the conversion of electricity into force or work. Pneumatic systems are only 10-30% efficient. Much of their inefficiency is due to the air leaks that are common in these systems.Air leaks also cause fluctuations in pressure that hurt cylinder performance. On the other hand, electric systems operate at 70-80% efficiency.

ctricity costs starts with efficiency, that is, the conversion of electricity into force or work. Pneumatic systems are only 10-30% efficient. Much of their inefficiency is due to the air leaks that are common in these systems.Air leaks also cause fluctuations in pressure that hurt cylinder performance. On the other hand, electric systems operate at 70-80% efficiency.

This chart shows how the utility cost of a pneumatic cylinder and an electric actuator compare in the same application.

- Product scrap

Product scrap is a quality issue, and electric actuators deliver the accuracy, repeatability, control, and long life needed to ensure consistently high quality. Air leaks in pneumatic systems cause pressure fluctuations which lead to inconsistent cylinder performance. Also, worn seals can lower accuracy.

- Lost time

Maintenance downtime has been covered, but there are two more time-wasting factors: cycle time and changeover time.

- Cycle time Pneumatic cylinders must stroke their entire length while electric actuators can be programmed to a stroke of any length. Shorter strokes take less time, allowing for more cycles per minute and higher throughput.

- Changeover time Some applications require the same equipment to produce a range of products. Pneumatic cylinders have to be changed manually – a time-consuming and inaccurate process. Electric actuators can be programmed for different set-ups, making the changeover process fast and easy.

Learn more

Our white paper on comparing the total cost of ownership of electric vs. pneumatic actuators will give you the information you need on this important issue. Download it here.

Interested in electric linear motion? Join the discussion at our LinkedIn group.

Ask an Engineer

Ask an Engineer