Lots more high-force linear actuator solutions with electric

By Tolomatic on June 26, 2018

Dan Schmit

Some machine designers still believe only hydraulic cylinders can handle high-force applications. But the fact is, electric high-force linear actuators are capable of 30,000 lbf (133 kN) maximum force and more, and they're affordable.

Some machine designers still believe only hydraulic cylinders can handle high-force applications. But the fact is, electric high-force linear actuators are capable of 30,000 lbf (133 kN) maximum force and more, and they're affordable.

Some designers think the selection of electric high-force linear actuators is limited. But the truth is the range of electric high force actuation solutions is always expanding. With this expanding range of solutions, more existing applications can be converted to electric and new applications can gain the benefits of electric actuation.

You can learn more in our white paper that compares electric linear actuators and hydraulic cylinders. Download your copy here.

Roller screws are the key

The power screw is at the core of any electric linear actuator’s capability, and electric high-force actuators often rely on roller screws because of their very high thrust capabilities. Here’s how they work:

In a roller screw, multiple triangular-threaded helical rollers surround the shaft. The rollers rotate within the nut while contacting the thread form of the shaft. This converts the motor’s rotary motion into the linear movement of the screw shaft.

Roller screws have a large surface area of rollers in contact with the screw threads. Screw components are often precision ground to provide continuous contact area, smooth motion and high thrust output.

The advantages of electric high-force linear actuators

Electric high force actuators offer significant advantages over fluid-powered cylinders:

Control

An electric actuator with servo drive/motor offers infinite control over position, velocity, acceleration/deceleration, output force, and more. Adjustments can be made on the fly, plus accuracy and repeatability levels are far better than those of a hydraulic system.

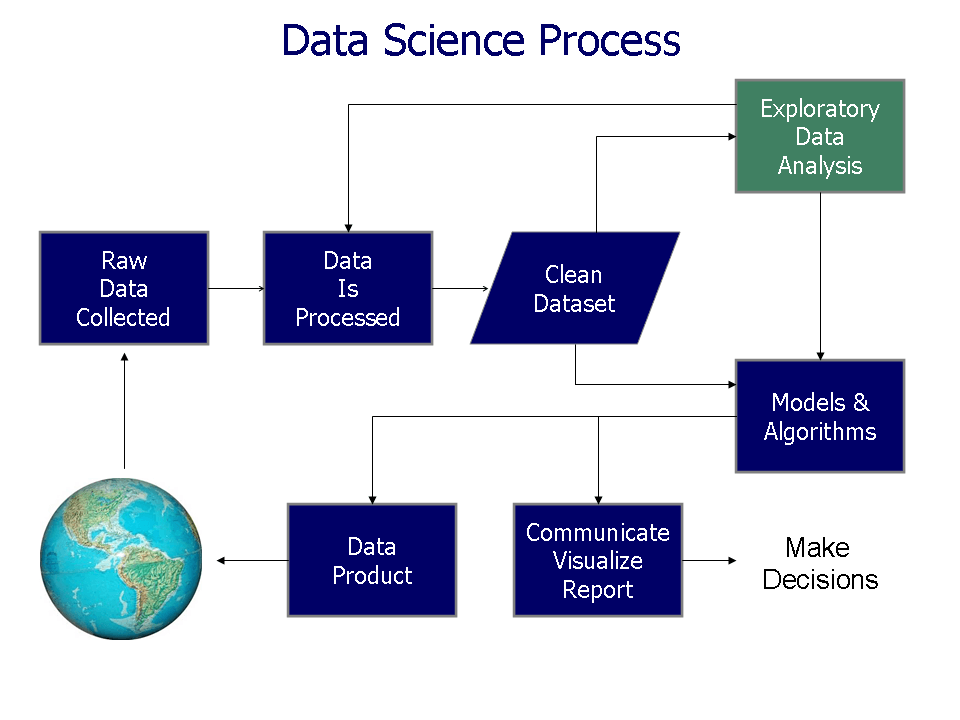

Data collection

Data collection

Sensing capability is built into an electric actuator’s servo system. Motor current monitoring tracks force and repeatability. The motor’s feedback device registers position and velocity. Standard hydraulic actuation systems don’t have data collection capabilities.

Sensitivity to temperature

Electric actuation systems can be selected to run at desired temperatures for the given amount of work required. Electric devices can be specified with optional extreme temperature grease for fast response in the cold.

On the other hand, hydraulic systems are sensitive to temperature extremes. Oil gets thick in the cold resulting in sluggish performance. In higher temperatures, oil degrades, and seals fail.

Electricity costs

Electric actuator systems operate in the 75-80% efficiency range. Hydraulic systems are typically only 40-55% efficient in  converting electrical power to motion.

converting electrical power to motion.

Life and maintenance

If an electric linear actuator is sized correctly for the application, no maintenance is required so there is no downtime. Our sizing software provides excellent sizing assistance. Hydraulic cylinders offer long service life; however, their maintenance requirements can mean downtime and added cost.

Environmental hazards

Electric actuation provides clean linear motion. Hydraulic actuation systems are prone to oil leaks that can create safety hazards, contaminate products and pollute the environment. Clean-up can be costly and time-consuming.

Force

Force is instantaneous with an electric actuator while a hydraulic actuator must wait for pressure to build. Hydraulic cylinder systems produce high forces; however, they often are oversized to improve control and may not operate at full force.

Our expanding high force family

Our high force electric rod-sty le actuator offering now features expanded stroke lengths up to 1.5 m (60 in.), allowing more flexibility for converting motion control applications from hydraulic or pneumatic cylinders to electric. Designed for high duty-cycle performance in demanding applications, the RSX, RSA, ERD and IMA electric rod-style product families utilize planetary roller screws for long service life.

le actuator offering now features expanded stroke lengths up to 1.5 m (60 in.), allowing more flexibility for converting motion control applications from hydraulic or pneumatic cylinders to electric. Designed for high duty-cycle performance in demanding applications, the RSX, RSA, ERD and IMA electric rod-style product families utilize planetary roller screws for long service life.

Our highest-force actuator, the RSX extreme force linear actuator series, is expanded from 600 mm to 1.5 m stroke length. The RSA and ERD are expanded from 450 mm to 1.5 m and 1.2 m, respectively.

The RSX extreme force electric linear actuator family includes two models: the RSX096 that provides forces up to 133.5 kN (30,000 lbf) and the new RSX080, an economical actuator solution with forces up to 80 kN (18,000 lbf). Even greater forces—50,000 lbf—are in development and will soon be available.

The RSA HT is available in four sizes, with forces up to 58 kN (13,039 lbf) and is the most flexible product line for fluid power replacement. The ERD stainless steel, hygienic electric actuator, rated IP69K for applications in the food and beverage industry, is available with forces up to 35 kN (7,868 lbf).

The IMA linear servo actuator and ServoWeld® resistance spot welding actuator platforms are also available at various thrust ratings and stroke lengths.

Resources

For an overview of high force linear actuators, download our white paper, Electric rod actuators vs. hydraulic cylinders: A comparison of the pros and cons of each technology.

Interested in electric linear motion? Join the discussion at our LinkedIn group.

Ask an Engineer

Ask an Engineer