Electric high-force linear actuators keep medical manufacturing clean

By Tolomatic on February 19, 2019

Machine designers know that hydraulic cylinders offer compact size and excellent power density. Designers also know there are serious drawbacks that make these cylinders problematic in many applications – problems such as inevitable leaks. Those leaks can be a significant hazard in manufacturing environments that demand cleanliness such as medical equipment production.

Machine designers know that hydraulic cylinders offer compact size and excellent power density. Designers also know there are serious drawbacks that make these cylinders problematic in many applications – problems such as inevitable leaks. Those leaks can be a significant hazard in manufacturing environments that demand cleanliness such as medical equipment production.

It used to be that hydraulic cylinders were the only choice when a designer needed a high-force linear actuator. Now there are electric high-force linear actuators that can replace hydraulics in many applications, offering clean operation as well as better accuracy and control.

For an overview of how electric high-force linear actuators compare to hydraulic cylinders, read our white paper, Electric rod actuators vs. hydraulic cylinders: a comparison of the pros and cons of each technology. Download it here.

The case study below describes a real-world example of the successful conversion of a hydraulic linear motion application to electric. This type of conversion is common since electric linear actuation offers so many benefits.

Plastics molding OEM needs clean, accurate actuators

The benefits of electric linear actuators were important to a plastic injection molding OEM who serves pharmaceutical and medical equipment manufacturers. Both of these industries require aseptic manufacturing conditions; however, the inevitable leaks that come with hydraulic systems pose a significant contamination risk. For this reason, the OEM looked for ways to eliminate hydraulics in processing equipment.

The OEM wanted a clean, electric solution that fit the existing space and provided the necessary force for a variety of applications. Also, the OEM needed actuators that precisely positioned the product, blowers, sealers and welders, and that were compatible with the existing PLC and motion control package.

Electric high-force linear actuator is clean solution

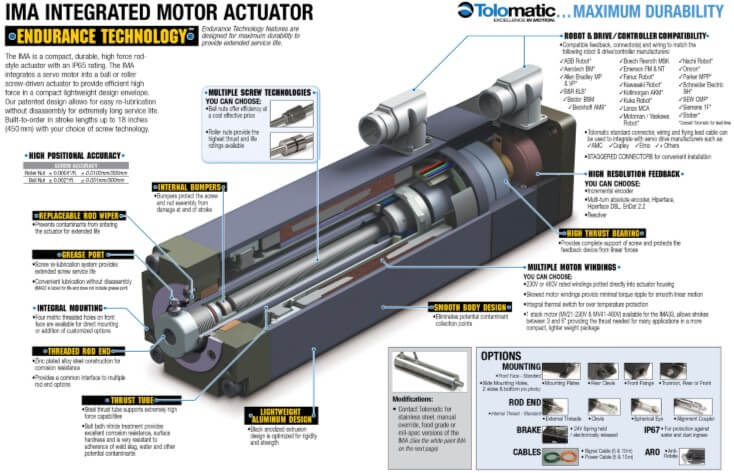

Our IMA linear servo actuators were selected for the application. As electric linear actuators, IMA actuators have no hydraulic fluid to leak — nothing to contaminate aseptic manufacturing processes.

IMA electric servo actuators have the compact size required by the OEM, so they easily fit the existing space in the machines. These electric actuators feature an integrated servo motor that provides accurate positioning control.

IMA actuators are offered in several sizes, each with the choice of ball or roller screw. This allows the OEM to accommodate all the size, force and budget requirements of its various machine designs.

The IMA actuators integrate smoothly with the OEM’s drive manufacturer. With IMA integrated servo actuators, it’s easy to swap PLC and servo drive controls without changing the motor or mechanical design.

IMA series linear servo actuators

The IMA linear servo actuator has a unique integrated servo motor design that results in a compact, heavy duty package. Available in both ball and roller screw configurations, IMA linear servo actuators provide forces up to 30.6 kN (6,875 lbf) even in high duty cycle applications. The IMA series of electric linear actuators utilizes a standard servo motor available with many feedback types.

Download our IMA brochure.

Watch our IMA video.

Resources

Download our white paper, Electric rod actuators vs. hydraulic cylinders: a comparison of the pros and cons of each technology, for an overview of how electric high-force linear actuators compare to hydraulic cylinders.