Need low cost linear motion? Total cost of ownership is key

By Tolomatic on March 19, 2019

How are industrial linear motion components like icebergs?

How are industrial linear motion components like icebergs?

They say 90% of an iceberg’s volume is hidden under water. When you buy linear motion components, specifically hydraulic and pneumatic cylinders, the real cost may be hidden as well.

If you’re looking for low cost linear motion, you may be attracted to the low purchase price of fluid power cylinders. However, purchase price is just the tip of the iceberg. To get a true picture, you need to look at total cost of ownership (TCO), including the long-term operating costs of the equipment.

For detailed information on how to determine the TCO of a linear actuator, download our whitepaper, Electric actuators vs. pneumatic cylinders: A comparison based on cost of ownership.

What is total cost of ownership (TCO)?

Total cost of ownership takes a long-term view of the cost of owning equipment. It takes into account the equipment’s purchase price and operating costs over its service life.

In terms of linear motion components, TCO means:

Total cost of ownership = initial purchase cost +

(years of service X yearly operating costs*)

*Yearly operating costs =

Replacement

+ maintenance

+ electricity

+ process control

+ lost production due to changeover

+ any other factors you can think of

See our infographic for an overview.

Achieving low cost linear motion

Specifying a linear actuator, whether fluid power or electric, involves understanding the application’s requirements, such as:

- Motion control capabilities/flexibility

- Positioning accuracy/repeatability

- Required service life

- Environment (IP rating, contamination, etc.)

To get a true picture of the size of your “iceberg,” include these factors in your evaluation of total cost of ownership:

Initial purchase price

Fluid-powered cylinders often don’t cost much initially and are fine for simple applications. However, if your application calls for greater flexibility, accuracy and control, the best linear motion system will cost more.

Service life

With ball and roller screw electric linear motion systems there’s no need to guess at this critical component in TCO calculations. Service life for those lead screws can be estimated using an industry-standard L10 life calculation. Engineers can only go on history to estimate the life of a fluid-powered cylinder.

Replacement

A high-performance (and initially more expensive) actuator may have a long service life and perform well throughout that life, making it lower cost in the long run.

Maintenance

An accurately-specified electric linear actuator is low-maintenance even in a demanding application that can wear down a low-cost actuator.

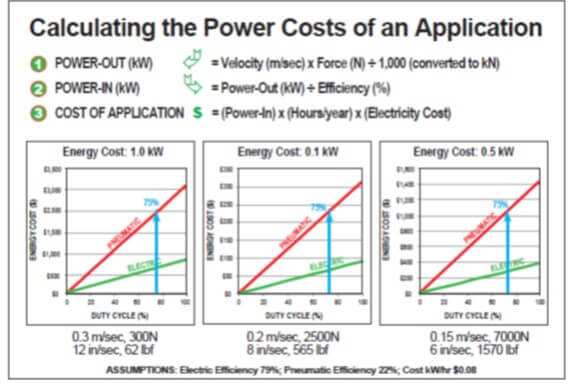

Electricity

Electricity

Electric linear actuators typically offer greater efficiency—up to 80%—while pneumatic systems have energy efficiencies as low as 10-30%, and hydraulic systems achieve only 40-50%.

Process control

An actuator with good control of force and velocity produces consistent product quality so product yield improves.

Lost production (changeover)

When the motion profile changes, electric linear motion systems can be reprogrammed quickly, whereas fluid-powered actuators require time-consuming, costly, manual tweaking.

Fluid-powered actuators may be adequate for some applications. However, for demanding, high duty cycle applications, high-performance electric linear motion systems can be more affordable when you look beyond the tip of the iceberg to total cost of ownership.

Learn more

For detailed information on determining the long-term cost of a linear actuator, download our whitepaper, Electric actuators vs. pneumatic cylinders: A comparison based on cost of ownership.