Extreme force electric linear actuator controls lumber drying

By Tolomatic on November 28, 2017

The lumber processing industry demands rugged, strong, reliable and accurate equipment in all its operations. Conditions can be harsh, with many operations exposed to outdoor climates and large temperature shifts. Logs are heavy, hard to control and liable to cause impact damage. Product quality is critical. Boards, beams and studs with too much retained moisture and those that are over-dried are rejected, cutting into tight profit margins. Machine designers who serve this industry need extreme force linear actuators to move heavy loads.

The lumber processing industry demands rugged, strong, reliable and accurate equipment in all its operations. Conditions can be harsh, with many operations exposed to outdoor climates and large temperature shifts. Logs are heavy, hard to control and liable to cause impact damage. Product quality is critical. Boards, beams and studs with too much retained moisture and those that are over-dried are rejected, cutting into tight profit margins. Machine designers who serve this industry need extreme force linear actuators to move heavy loads.

Hydraulic cylinders have been the go-to, but they have limitations, such as inconsistent control, leaks, temperature sensitivity, maintenance requirements and lack of feedback.

Now there are electric rod actuators powered by roller screws that can meet the requirements of these high force applications. Get our white paper for a comparison of electric high force linear actuators and hydraulic cylinders.

Hydraulic cylinders lack consistent control

A lumber processing equipment company was having trouble controlling in-feed velocity in its kiln-drying operation. When the feed rate was too slow, lumber was over-dried, causing cracking, distortion and damage. Conversely, when the feed rate was too rapid, cold lumber dropped the temperature of the kiln, causing under-drying and too much moisture. Boards that were either too dry or not dry enough were not ideal for the planning process that followed. This led to more rejects and lower profits.

Hydraulic cylinders were supposed to control the feed rate of the lumber carts but were doing a poor job in two key areas:

- Speed In-feed speed was difficult to control due to temperature changes in the outdoor environment. Extreme low and high temperatures caused fluctuations in cylinder speed. There were other cylinder problems as well, including sluggishness in cold temperatures, oil degradation and premature seal wear.

- Feedback Because hydraulic cylinders don’t have feedback capabilities built in, a separate system had to be designed. In this case, speed was monitored by an external encoder mounted on a tire. As the lumber carts were indexed, the tire/encoder would rotate. The system had major flaws, though. If the tire was not positioned properly or the lumber stacked unevenly, the feed rate would not be properly measured.

The hydraulic cylinders were in a hard-to-reach spot, so it was difficult to perform required maintenance. Also, leaking hydraulic fluid was an environmental concern.

Extreme force electric linear actuators are solution

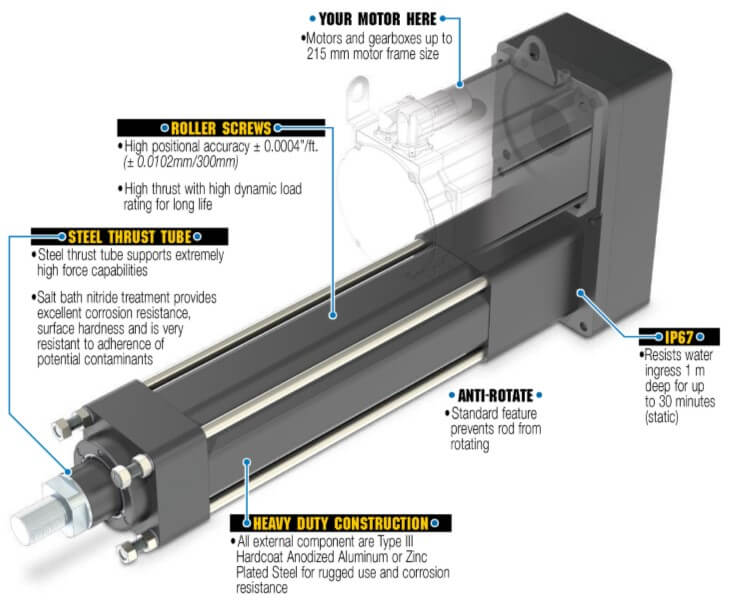

The lumber company’s engineers and Tolomatic experts selected RSX096 extreme force electric linear actuators with an IP67 rating for this application. The high-thrust roller screw actuators provide the thrust capacity necessary to index the large loads, and the IP67 protection allows them to operate effectively in the wet, muddy, dusty outdoor environment.

As electric rod actuators, RSX actuators offer tight control of positioning and velocity. RSX actuators work reliably in all temperatures, since they have no oil to thicken in the cold or break down in heat. Plus, no oil means no harmful leaks.

The long-lasting roller screw that powers the RSX makes the actuators virtually maintenance-free with a long service life. Additionally, the RSX actuators in this application are combined with servo motors which provide absolute positional feedback, eliminating the need for the unreliable tire/encoder feedback assembly.

RSX electric rod actuators

RSX electric rod actuators

The RSX family features extreme force electric linear actuators that are more efficient and flexible than hydraulic cylinders. Designed and tested for 100% duty cycle, RSX actuators are roller screw powered and can replace hydraulics without the messy leaks or noisy operation.

The first RSX extreme force actuator in the family, the RSX-096 is capable of 30,000 lbf (133.5 kN). It is rated IP67 to withstand extreme conditions and cold-weather operation.

Download our RSX family catalog.

Learn more

For a thorough review of hydraulic and electric actuation, download our white paper, Electric rod actuators vs. hydraulic cylinders: a comparison of the pros and cons of each technology.

Interested in electric linear motion? Join the discussion at our LinkedIn group.