Planetary Roller Screws

High Force and Efficient Operation in a

Compact Package

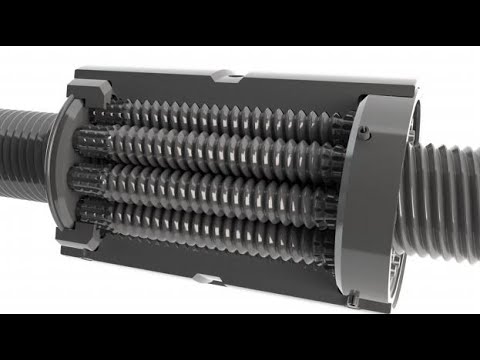

Roller screws—also called planetary roller screws—have precision-ground screw threads that match multiple precision-ground rollers in the nut. These rolling elements provide more points of contact, allowing for higher force capability and longer life. Tolomatic roller screws set themselves apart by having a very deep case (surface) hardness and a high Dynamic Load Rating (DLR*).

Tolomatic manufactures thousands of roller screws per year for applications around the world.

How do we ensure top-tier performance for our roller screws?

Tolomatic’s planetary roller screws are manufactured in the United States using state-of-the-art equipment to maintain strict tolerances and the highest quality standards.

-

- Configurable stroke lengths

- Industry best lead times

- Extensive quality testing and verification completed in-house

- Extended lifetime, no matter how demanding the location or application

- Appropriate for smaller, lightweight designs and machine concepts

Features & Ordering

Download the Roller Screw Brochure for full details on features

Roller Screw Features

Roller Screw Features & Advantages

What features can I expect from Tolomatic planetary roller screws?

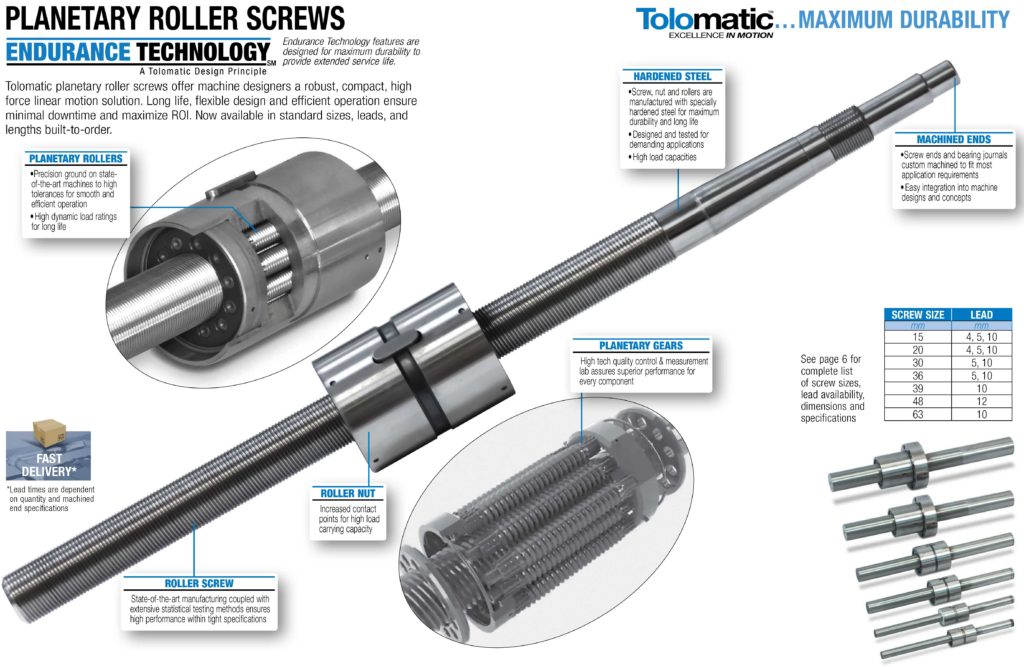

- Planetary rollers that are precision ground on state-of-the-art machines to high tolerances for smooth, efficient operation and high dynamic load ratings for long life

- Roller nuts with increased contact points for high load carrying capacity

- Roller screws made using state-of-the-art manufacturing coupled with extensive statistical testing methods that ensures high performance within tight specifications

- Planetary gears with high tech quality control and measurement labs to assure superior performance for every component

- Machined screw ends and bearing journals custom machined to fit most application requirements

- Easy integration into machine designs and concepts

- Screw, nut and rollers that are all manufactured with specially hardened steel for maximum durability and long life

An Overview of Planetary Roller Screws

Roller screws are designed to provide high force and efficient operation in a compact package. This unique design offers higher forces and longer life in a smaller package compared to ball screws, increasing a machine designer’s ability to create compact machine concepts. Tolomatic roller screws are manufactured to meet strict tolerances and the highest quality standards ensuring that each roller screw provides top-tier performance.

Planetary roller screws from Tolomatic come with:

- Industry best lead times

- Configurable stroke lengths

- The option to machine screw ends to OEM specifications

- Extensive testing and verification in Tolomatic’s research and development lab

- Long, reliable lives in thousands of demanding applications worldwide through use in Tolomatic’s RSH, IMA, RSA, RSX, TRS, ServoChoke and ServoWeld actuator platforms

Roller Screws vs. Ball Screws: What’s the Difference?

Planetary roller screws are capable of handling heavy loads and contain precision ground rollers engaged with a precision ground screw. When compared to a ball screw of the same size and lead, the roller screw components are designed to have increased points of contact and a larger contact radius. This results in less stress per point of contact and allows roller screws to carry higher loads per given size.

Ball screws are capable of handling moderate loads and contain multiple ball bearings that cannot be made below a minimum size. When compared to a roller screw of similar size and lead, the ball bearings’ radius requires a coarser pitch resulting in fewer points of contact. This pitch combined with the smaller contact radius and a design that allows the bearings to contact each other, limits the ball screw’s dynamic load rating leading to lower forces and shorter life than a roller screw.

Here’s a breakdown:

Dynamic Load Rating

- Planetary roller screws have a very high dynamic load rating.

- Ball screws have a medium dynamic load rating.

Lifetime

- Planetary roller screws have a lifetime many times greater than ball screws.

- Ball screws have a medium lifetime.

Shock Loads

- Planetary roller screws can handle very high shock loads.

- Ball screws can handle moderate shock loads.

Relative Space Required

- Planetary roller screws require minimal space.

- Ball screws require moderate space.

Acceleration

- Planetary roller screws have a high acceleration rate.

- Ball screws have a moderate acceleration rate.

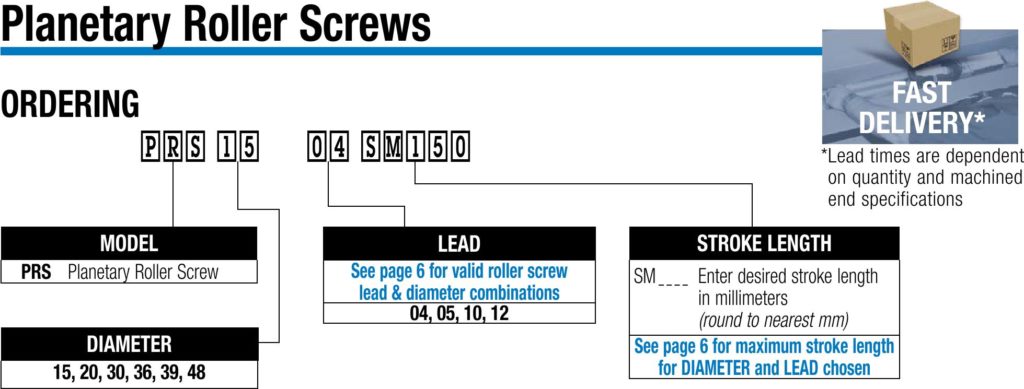

Roller Screw Ordering

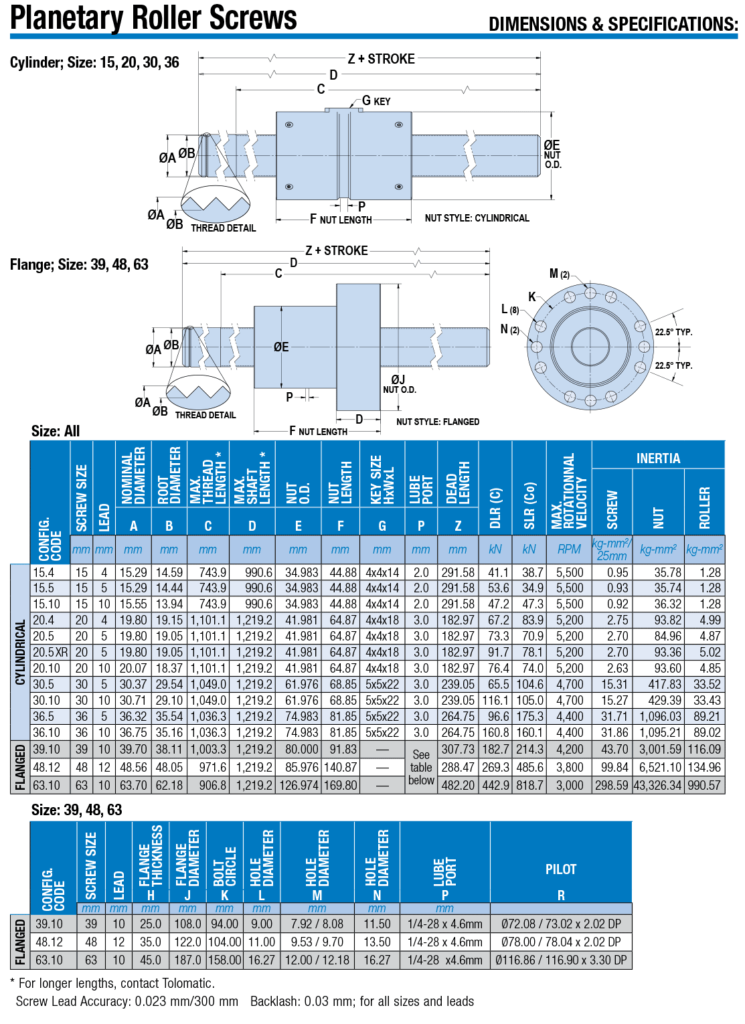

Dimensions

Roller Screw Dimensions & Specifications

Ask an Engineer

Ask an Engineer