Electric high force linear actuators with roller screws rival hydraulic

By Tolomatic on November 1, 2016

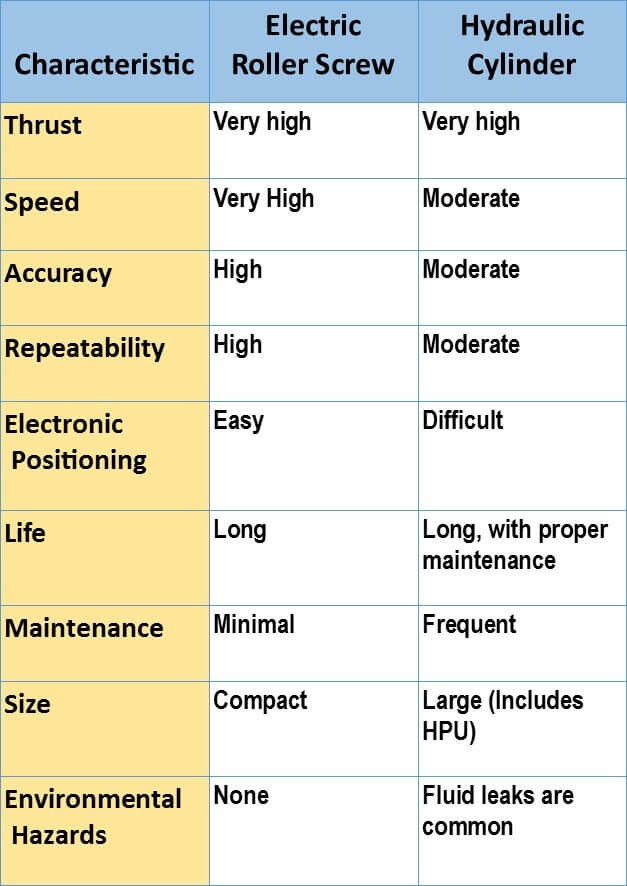

When you’re specifying a high force linear actuator, your application’s requirements call the shots. It used to be that hydraulic cylinders were your only recourse when high force was needed. Now there are electric linear actuators with roller screws that rival the high force, high thrust, high torque capabilities of hydraulics. Plus, these electric actuators deliver high speed, great accuracy and repeatability and long life. Electric roller screw actuators are definitely an alternative to consider.

When you’re specifying a high force linear actuator, your application’s requirements call the shots. It used to be that hydraulic cylinders were your only recourse when high force was needed. Now there are electric linear actuators with roller screws that rival the high force, high thrust, high torque capabilities of hydraulics. Plus, these electric actuators deliver high speed, great accuracy and repeatability and long life. Electric roller screw actuators are definitely an alternative to consider.

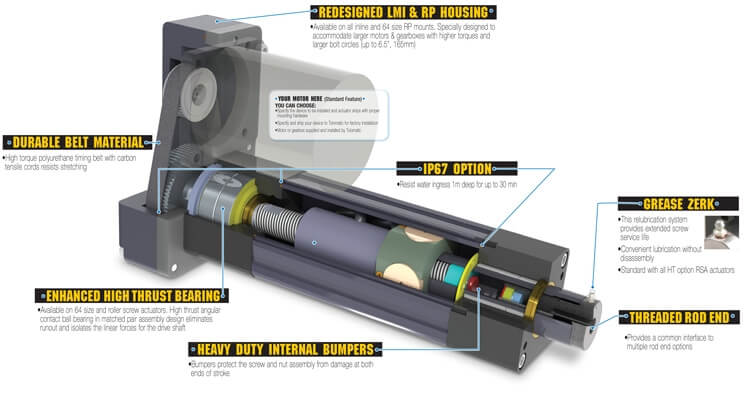

Our new line of RSX extreme force, hydraulic class electric linear rod actuators are designed to meet the growing need for high force in linear motion. The first product in this line, the RSX096, is available now and can deliver 30,000 lbf (133 kN) of thrust.

As the component responsible for converting rotary into linear motion, the power screw is critical in any electric linear actuator. As a machine designer, you’ll want to understand the advantages of the three screw types: acme, ball and roller. Tolomatic’s guide is a great resource to download and have at hand. Download it here.

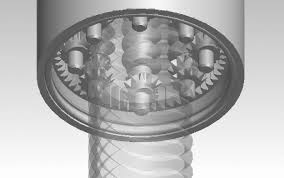

How roller screws work

The screw’s thread form is generally triangular. In the screw, multiple threaded helical rollers are assembled in a planetary arrangement around the  shaft. The rollers rotate within the nut while contacting the thread form of the shaft. This converts the motor’s rotary motion into linear movement of the screw shaft.

shaft. The rollers rotate within the nut while contacting the thread form of the shaft. This converts the motor’s rotary motion into linear movement of the screw shaft.

Screw components are usually ground to provide continuous contact area, smooth motion, and high thrust outputs. However, in some screws components are rolled rather than ground. This saves cost but sacrifices performance.

Roller screws have a large surface area of rollers in contact with the threads so they have higher load carrying capacities than ball screws of the same diameter. This screw technology is well suited for applications where extremely high force is required or if an application requires extended life, high degrees of precision and programmability.

Electric high force linear actuator advantages

force linear actuator advantages

It used to be that if you had a high force or heavy load application, a hydraulic cylinder was your only option. Initial cost for the cylinder was low, but along with it you got a high risk of hydraulic fluid leaks plus a space- and energy-consuming hydraulic power unit (HPU).

Now there are electric actuators powered by roller screws capable of delivering forces equal to hydraulic cylinders. These actuators are compact and offer very high levels of accuracy and repeatability, making them excellent choices for highly precise applications. They can operate at high speeds with good acceleration, as well.

Being electric, these actuators are easily programmable and able to execute even the most complex linear motion profiles. They are pollution-free, long-lasting and need minimal maintenance.

Tolomatic high force linear actuators

We offer a range of high force actuators, all with long-lasting standard roller screws:

- RSA-HT heavy duty, high force electric rod actuators. Thrust up to 13,039 lbf (58 kN)

- ERD hygienic electric actuator. Thrust to 7,868 lbf (35 kN)

- IMA integrated servo motor actuator. Thrust to 6,875 lbf (30 kN)

- IMA food grade actuator. Thrust to 6,875 lbf (30 kN)

Learn more

Download our guide: Which Screw? Picking the right technology.

Ask an Engineer

Ask an Engineer