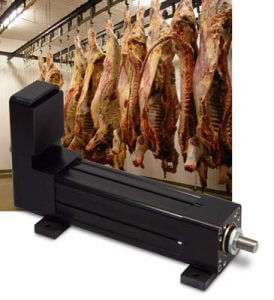

Walking Beam in Meat Plant

Product Family: Electric

Product Used: RSA-HT Heavy Duty, High Force Electric Rod Actuators

Product Type: Modified Standard

Application Requirements:

Stroke: 406 mm (16 in)

Application Description:

Walking beam pulls sides of pork and beef through the chilling / aging process.

Challenge:

A large meat processing plant was expanding and upgrading its facility. Due to contamination concerns, the company was evaluating whether to continue to use hydraulics with the "walking beam" application or to consider an alternative way of pulling sides of pork and beef through the chilling process. Since there were large amount of product in the walking beam areas, any leaks from the hydraulic cylinders could create a major contamination event which could cost large amounts of money in disposed product. Additionally, the company was also concerned with flexible mounting for use in both new expansion installs as well as upgrading from existing hydraulic installations.

Tolomatic Solution:

The wide array of screw options offered on the Tolomatic RSA provided an effective electric solution that exceeded the performance of a hydraulic cylinder with greater process repeatability. The total cost of ownership played a major factor in the decision process. Over the life of the actuator, when energy costs, maintenance and service life were considered the RSA electric actuator is a more economical solution than a hydraulic cylinder. Collaborating with the local distributor, Tolomatic support staff was on-site to insure prompt, problem-free installation during both expansion and upgrade. Tolomatic modified the mounts on the RSA HT heavy duty high force electric actuator to match the hydraulic cylinder mounts which eased the phase two upgrade.

Customer Benefit:

- Eliminated the risk of hydraulic contamination to pork or beef products

- Reduced downtime during phase two upgrade with quick and easy installation

- Reduced maintenance and operating cost compared to hydraulic systems

FBT-033-E

Ask an Engineer

Ask an Engineer