Solving Harsh Environment Challenges for Linear Motion

By John Fenske on November 3, 2025

![]()

Electric linear actuators are often selected for linear motion applications because they provide clean and consistent control and performance. Providing these benefits to rugged applications means that electric linear actuators must be designed to meet harsh environmental challenges such as extreme temperatures, debris and moisture ingress, corrosion, shock and vibration. Engineers working with these rugged applications know that demands go beyond linear motion basics.

Industries such as lumber processing and mining require linear actuators that can stand up to many kinds of harsh conditions. To ensure consistent performance when faced with a variety of environmental challenges, it is beneficial to source electric linear actuators from providers that are experts in addressing the unique requirements.

Here are some examples of how Tolomatic’s electric linear actuators meet tough environmental challenges:

Casting Manufacturing Challenge: Extreme Heat and Debris Ingress

Two RSX15 Extreme Force Rod-Style Actuators replaced the hydraulic actuators for a high-quality casting manufacturer. The actuators moved castings out of their molds, requiring approximately 66 kN (15,000 lbf) of force — and even more if the casting was left to cool within the mold.

This manufacturing environment subjects the actuators to extreme heat as well as dust and debris. The RSX15 actuators were equipped to handle such harsh conditions due to their IP65 rating and broad temperature capabilities.

Lumber Processing Machinery Challenge: Shock Load and Ingress

A lumber processing equipment manufacturer replaced hydraulic cylinders in its machines with electric actuators for positioning the machine’s rollers on the planer. Using Tolomatic’s RSA64HT roller screw actuator, the manufacturer eliminated hydraulic fluid leaks from the machine. The actuator was a great fit for the rugged environment thanks to its IP67 rated sealing for protection from splashing water and sawdust ingress.

The rugged design of the RSA64HT, including a custom steel head with integrated trunnions and a roller screw to increase contact area, enabled the actuator to perform reliably in a high shock load environment.

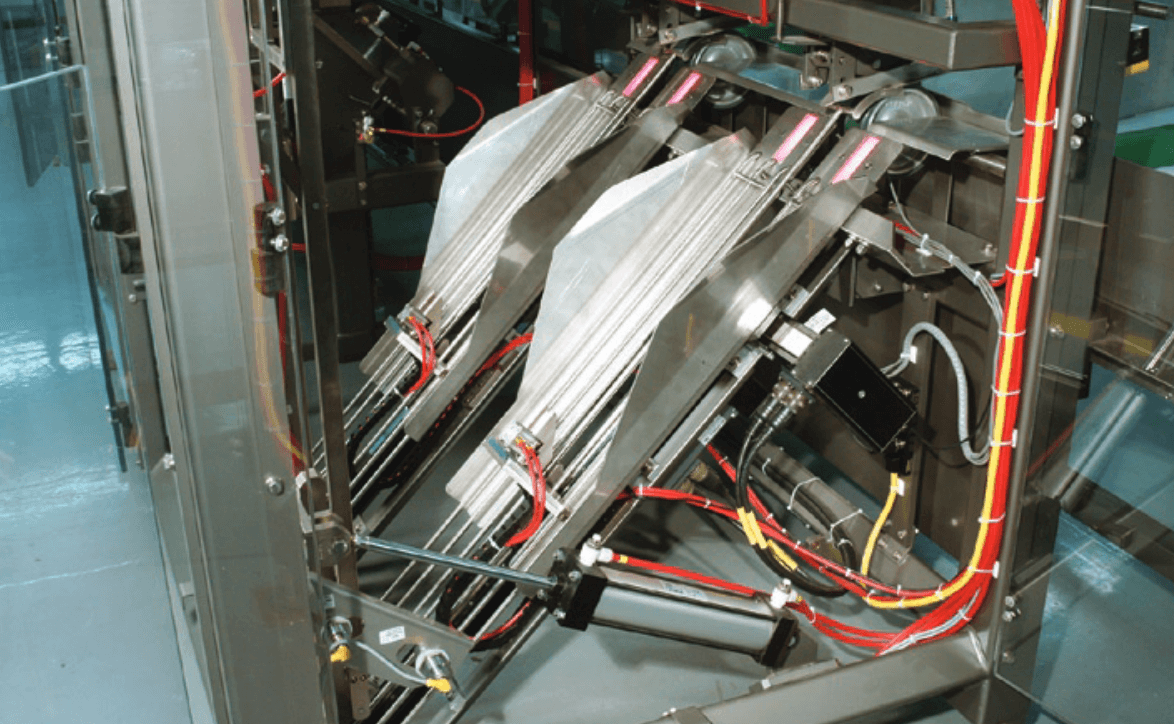

Packaging System Challenge: Debris Ingress and Corrosion

A packaging equipment manufacturer’s system for bag handling, filling and sealing for high particulate products (salt, dirt, fertilizer, etc.) was encountering issues when customers began using cheaper bags that were inconsistently sized. The irregular sizes hindered the performance of the system because the bags’ variable dimensions caused errors in handling, filling and sealing. As a solution, the manufacturer incorporated customized Tolomatic electric actuators to improve its system’s design.

Implementing Tolomatic’s B3S10 rodless style actuators enabled the packaging machinery to precisely position the incoming bags, automatically compensate for the irregular sizes and ensure the bag filling machines maintained high accuracy and speed. To eliminate the risk of particulate ingress, a purge port was added to the B3S10 to maintain positive pressure in the body of the actuator. External component materials were also evaluated for more corrosion resistant alternatives.

The packaging equipment manufacturer couldn’t find an off-the-shelf solution, so they worked with Tolomatic to modify a standard actuator to meet their needs. The final result is a robust electric actuator with excellent dust, dirt and corrosion protection — especially important due to the variety of fillings that could be packaged such as salt, dirt and fertilizer.

High-Speed Train Challenge: Industry Standards, Shock, Vibrations

The wheels of high-speed train cars wear down over time as the train moves around curves. One high-speed train car manufacturer provides long-term maintenance contracts to its customers. But to reduce maintenance frequency, a cost-effective solution was desired to reduce the wheels’ wear rate. The manufacturer looked for an actuator that could steer the car’s wheels as the train traveled around the curve, but no actuator existed on the market that could meet stringent railway industry standards for fire, smoke and vibration.

A solution was found in a customized IMA44 integrated linear servo actuator from Tolomatic. Beginning with the IMA44 as a base design, Tolomatic modified the actuator to meet the UNE-EN 61373:201 level 3 Shock & Random Vibration Standard as well as Fire & Smoke Standard EN 45545 level HL3. After customization, the manufacturer had a compact, heavy-duty actuator that improved its rail car design by reducing the wear rate and increasing the time between maintenance intervals.

Battery Manufacturing Challenge: Corrosion

At a battery manufacturer, an automated fluid-powered acid bottle handling system required an upgrade to electromechanical actuation. Because of the corrosive nature of this application, the new actuators required stainless steel construction. However, many of the actuators initially implemented were unsuccessful due to corroding metal and degrading elastomers.

Tolomatic provided the RSH series actuator as a solution because of its proven success in corrosive environments. The RSH is effective because it is constructed with 316 stainless steel compared to the lower 300 series steels used in other actuators. The seals of the RSH also hold up well in corrosive environments because they are primarily composed of polytetrafluoroethylene (PTFE), which features superior chemical resistance compared to actuators which use nitrile or other elastomeric seal materials.

Mining Hopper Control Challenge: Ingress and Corrosion

In a mining application, one customer replaced pneumatic actuators with electric actuators to control hopper doors to the underground mine. Because this environment has a high concentration of salt and particulates, the actuators used must have excellent ingress and corrosion protection to prevent downtime. The customer selected our RSX actuators because they provided high force and reliability. To meet the environmental challenges, Tolomatic also modified the RSX with special materials and coatings that combat corrosion.

Work With Experienced Custom Manufacturers

While standard Tolomatic electric linear actuators meet many performance and environmental protection challenges, sometimes custom modifications are necessary to meet the most rugged requirements. That’s why our extensive experience in delivering high-quality custom solutions is key to ensuring our customers’ success in some of the toughest environments.

Ask an Engineer

Ask an Engineer