How accurate is an actuator?

By Ryan Klemetson on March 2, 2021

Do you want to hit the bulls-eye, or the same spot over and over?

Many engineers want to boil down the accuracy of their linear motion system to a single value, but it’s not as simple as that.

Accuracy and repeatability are two separate but related concepts of a linear motion system. The motor, drive and actuator itself all influence accuracy and repeatability. It’s quite possible you may need repeatability more than accuracy.

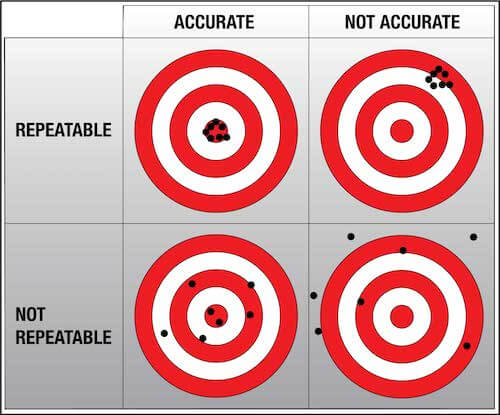

Accuracy and repeatability refer to the precision of the system. These two factors, along with resolution, make a big impact on overall system precision. Think of accuracy and repeatability as darts on a dartboard.

Accuracy—The bulls-eye. How close you come to the target, though not necessarily the same position.

Repeatability—How close to the same location, even if not close to the target.

Resolution—The smallest increment of measurement or movement. Higher precision also requires higher resolution. The motor encoder is the largest contributing factor to system resolution.

Accuracy and repeatability values are a sum of all components

The total precision of any motion system is a summation of accuracy and repeatability values from the linear components within the system.

Mechanical tolerances

- All mechanical components have tolerances which vary based on the manufacturing process used in their construction. This includes extrusion of the rod, linear bearings, bushings and pulleys. Tolerances can be related to feature size, bow, and twist.

Tooling (components mounted to carriage)

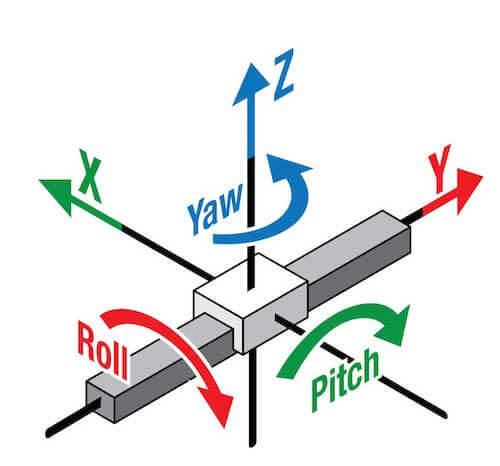

- Tooling can create a wobble effect . Yaw, roll and pitch affect direction and angle.

Backlash

- Backlash is the amount of linear movement between the screw and nut without rotation of the mechanism. Backlash affects accuracy and repeatability along the X axis.

Lead accuracy

- Lead is the distance the nut advances with each rev of the screw. Pitch is the axial distance between the screw threads. Pitch = Lead for single start screws. Even precision rolling processes produce screws with some variation in the screw pitch—thereby affecting the lead as the screw is turned. This affects accuracy but not repeatability along the X axis.

Belt accuracy

- Tolerances in the construction of the timing belts and drive pulleys can create minor positioning errors. This variance affects accuracy. It affects repeatability when belt length is less than stroke length.

System resolution

- Higher precision also requires higher resolution. The encoder position provides position feedback.

Summary

Know your application.

- High precision comes at a higher cost. Some applications require high level of repeatability but not a high amount of accuracy. System resolution has an effect on both.

The key to success is understanding what your application requires and choosing the actuator accordingly. By doing so, you can avoid excess costs and design a system with the best overall value.

Learn more about accuracy and repeatability. Download our white paper.

Introduction to accuracy and repeatability in linear motion systems

Questions about the accuracy and repeatability of your linear motion system? Ask an engineer.

Ask an Engineer

Ask an Engineer