How the ServoWeld® Actuators Work

Superior Integrated Servo Motor Actuators

Tolomatic’s ServoWeld® family of integrated servo actuators are designed for best-in-class performance with factors that are most important for resistance spot welding gun OEMs, automotive OEMs and tiered suppliers.

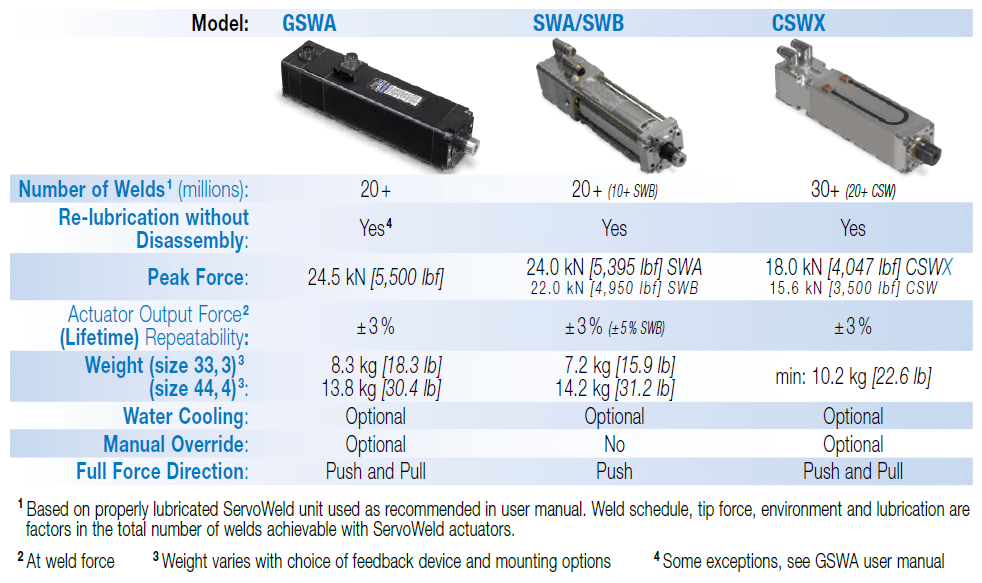

Number of welds/life

Tolomatic’s superior roller screw design has the highest dynamic load rating for more welds than any competitive technology (other roller screws, ball screw, pneumatic).

Force Repeatability

Skewed winding designed for welding minimizes motor cogging and better force repeatability to the industry best 3% over the life of the actuator.

Efficiency

All elements of actuator (winding, screw, seal, bearings) are designed and chosen to optimize the efficiency of the actuator system and provide the most energy efficient solution on the market.

Welds per minute

All elements of the actuator (winding, screw, seal, bearings) are designed to last and run as cool as possible in welding applications, with the ability to add water cooling as an option. This means more weld per minute than any competitive technology (other roller screws, ball screw, pneumatic).

Weight

Tolomatic integrated ServoWeld actuators minimize weight when designed into the weldgun. Additionally, Tolomatic can customize actuators for a specific weldgun to provide industry leading light-weight designs.

Lifetime cost

By building the longest lasting, most efficient and highest weld per minute actuators on the market, Tolomatic actuators provide the lowest total cost of ownership (lowest cost per spot weld).

Broadest Product Offering

Tolomatic offers the broadest, most capable family of integrated servo actuators for resistance spot welding

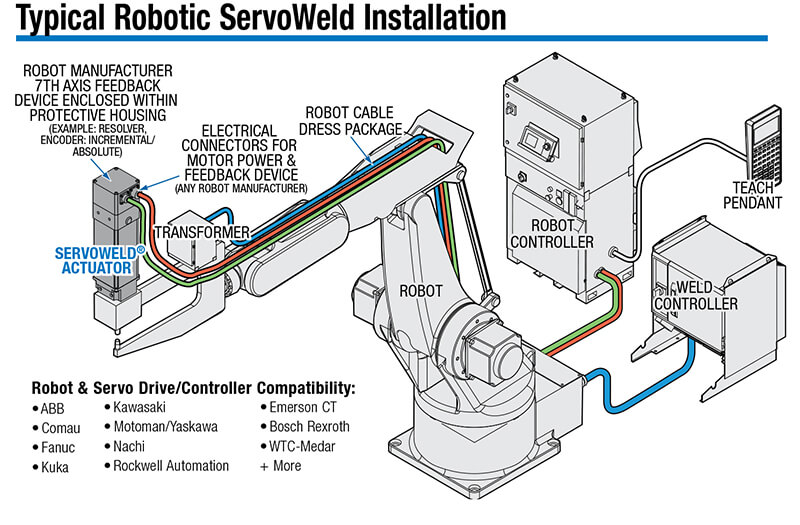

Robotic Welding System

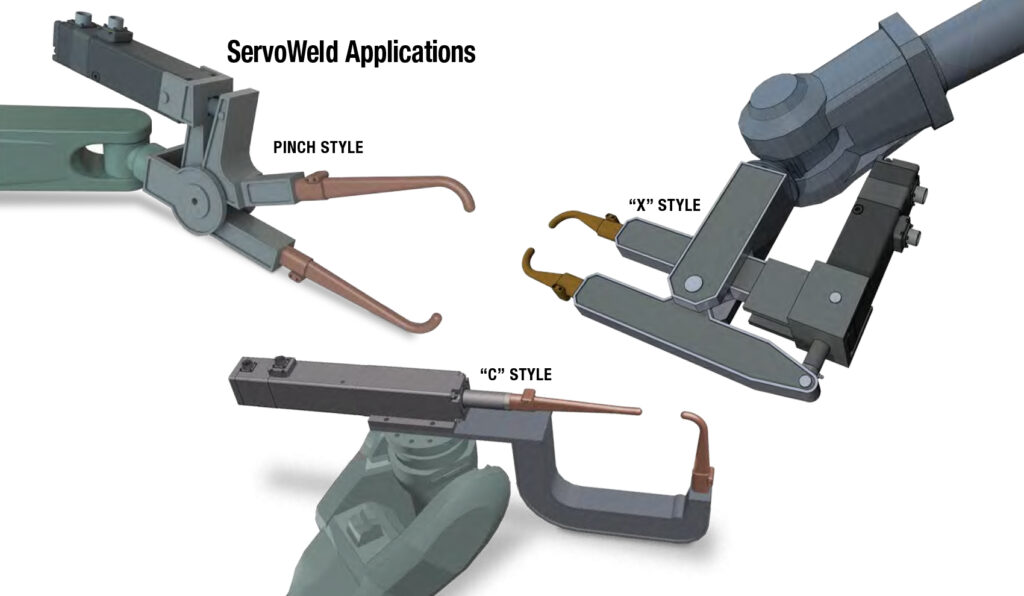

ServoWeld Weldgun Applications