SWA/SWB ServoWeld® Integrated Actuators

ServoWeld® SWA & SWB integrated servo spot welding Actuators offer light weight with high performance.

Tolomatic’s ServoWeld family of lighter weight integrated servo motor actuators for resistance spot welding (RSW) provide a cost-effective actuator design and best-in-class performance. SWA/B actuators provide users the lowest lifetime cost (lowest cost per spot weld) by providing the highest quality welds (best force repeatability) combined with the longest lasting actuators. ServoWeld SWA/B integrated servo spot welding actuators are highly efficient, and the broad product family has many choices to optimize weight and performance.

SWA/SWB integrated servo motor actuators offer:

- 20+ million cycles for SWA models and 10+ million cycles for SWB

- Standard roller screw with highest dynamic load rating for more welds over competing roller screws, ball screws or pneumatic actuators

- Skewed motor windings designed for welding minimizes motor cogging for the best force repeatability

- Light-weight actuator design

- Forces to 4,000 lbf (17.8 kN)

- Optional water cooling

Features & Ordering

Download the SWA/SWB Brochure for full details on features

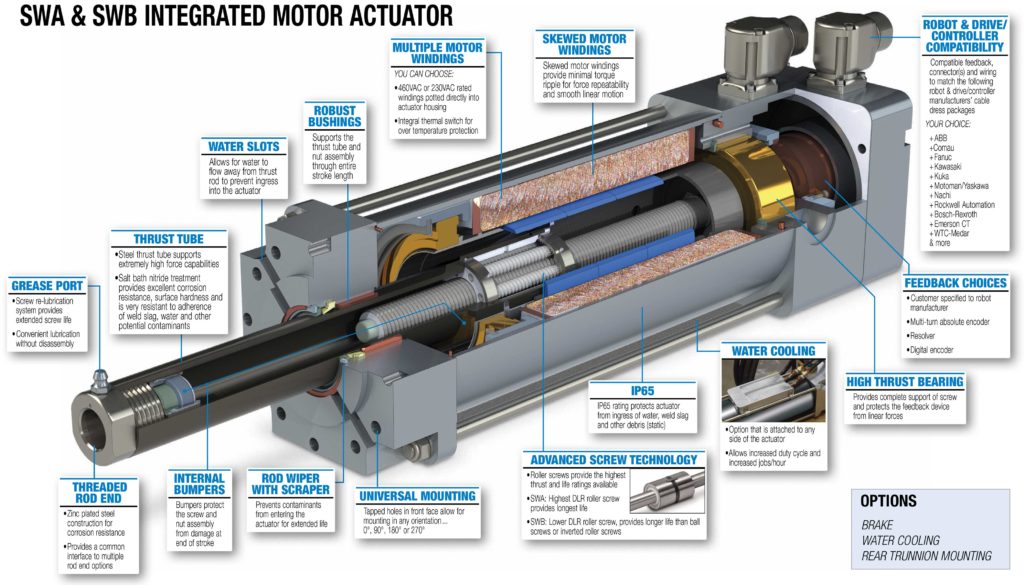

ServoWeld® SWA/SWB Integrated Motor Actuator Features

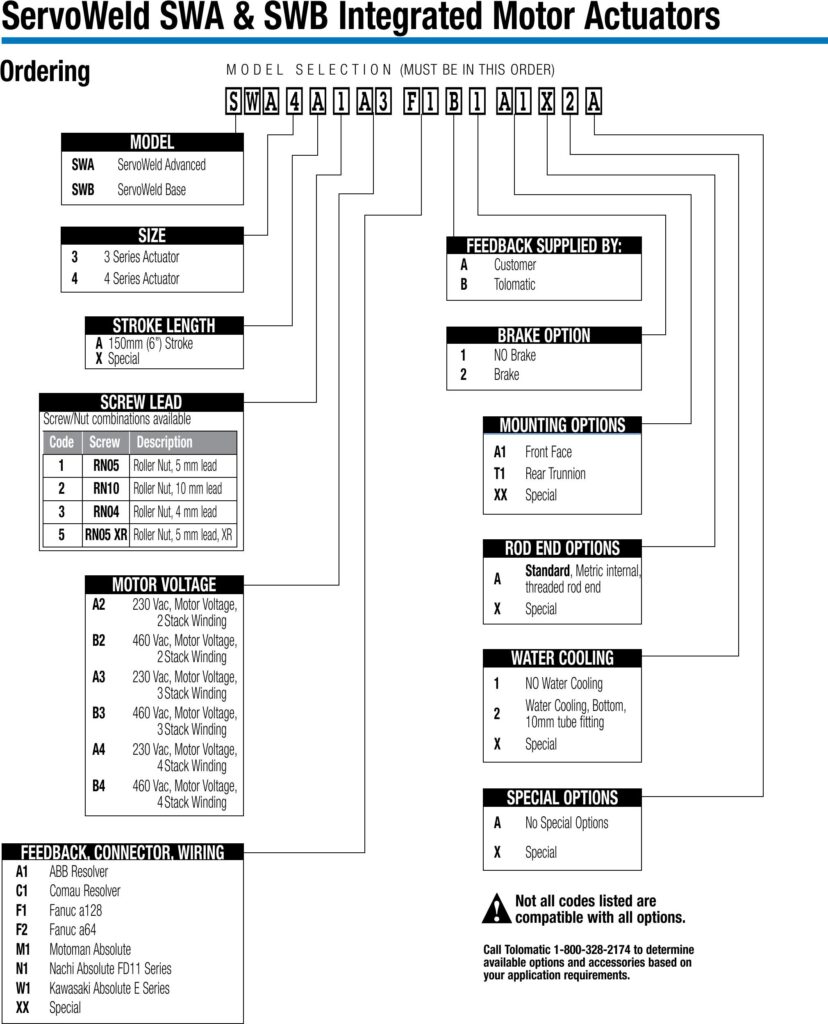

ServoWeld® SWA/SWB Ordering

Specifications

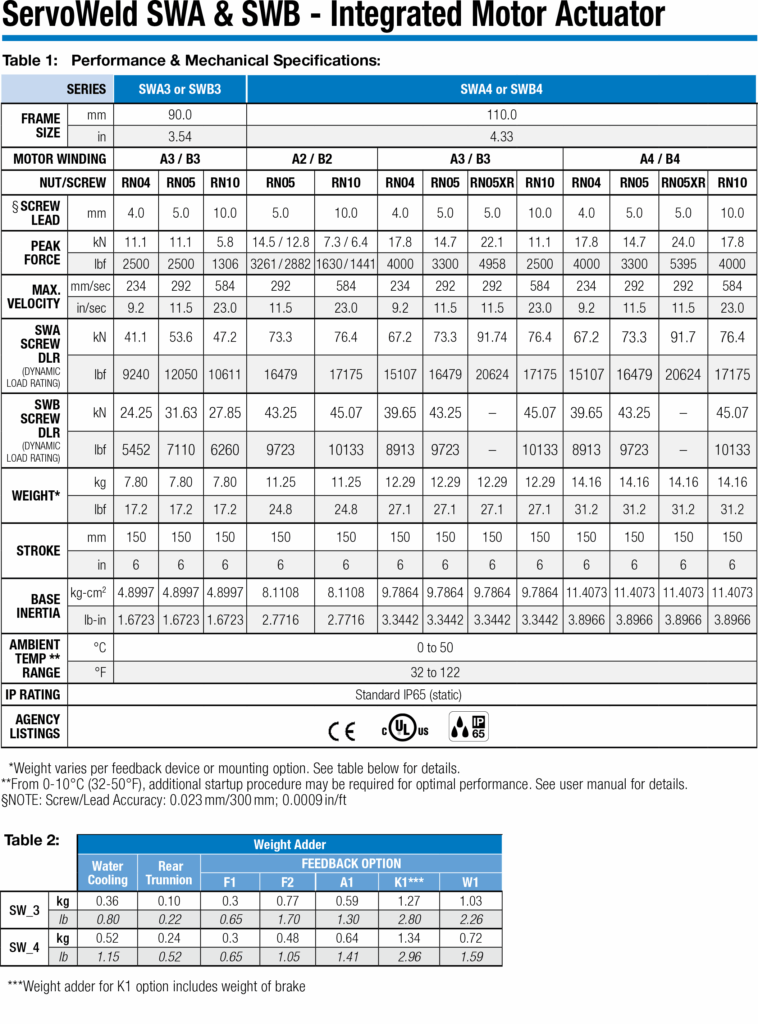

| Specifications | Units | 3 | 4 |

|---|---|---|---|

| Maximum Stroke | in (mm) | 6 (152) | 12 (305) |

| Maximum Force | lbf (kN) | 2,500 (11.1) | 4,950 (22.0) |

| Maximum Speed | in/sec (mm/sec) | 23 (584) | 23 (584) |

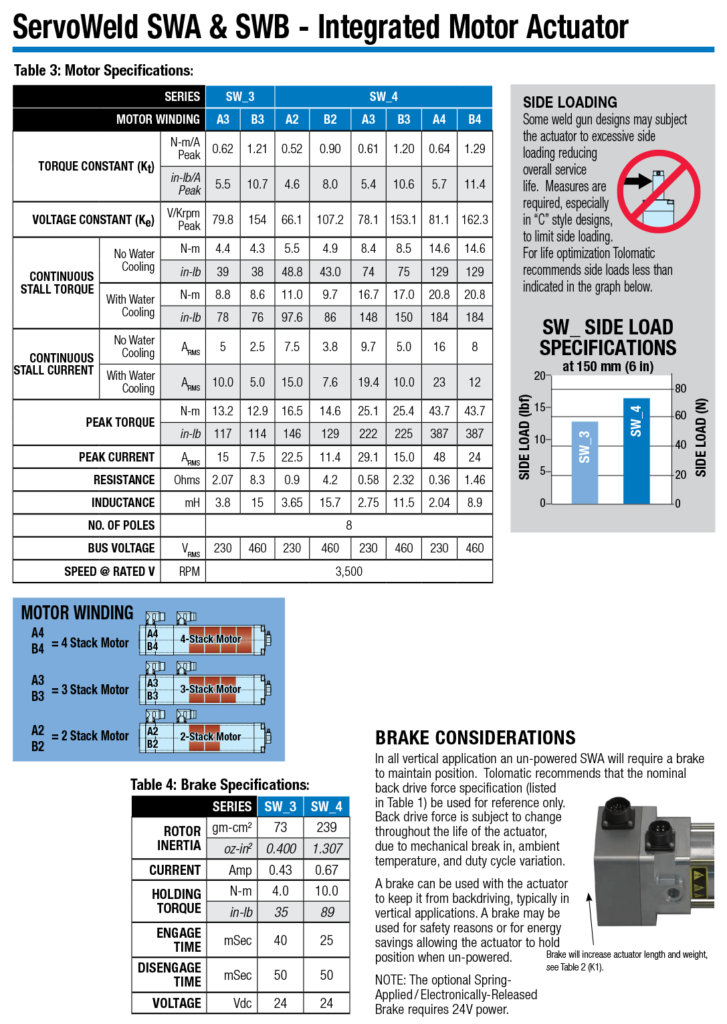

SWA/SWB Motor, Brake & Side Loading Specifications

SWA Mechanical Specifications

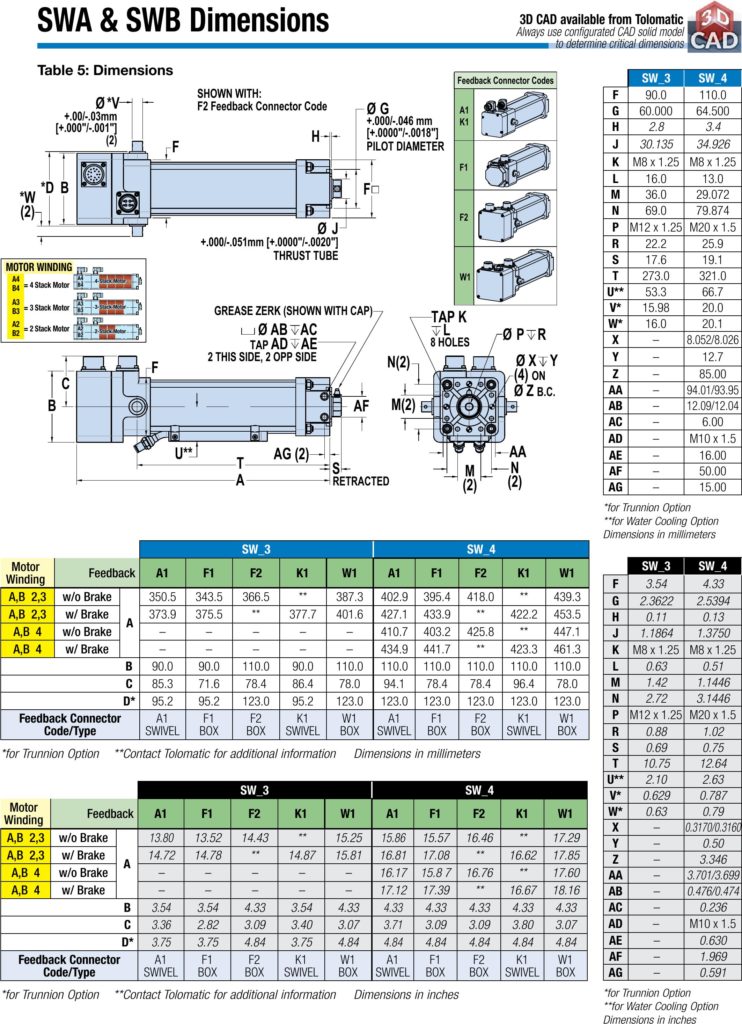

Dimensions

SWA/SWB Actuator Dimensions

Manuals & Part Sheets

Additional Resources

Information Center:

Application Checklists

Catalogs & Brochures

- Corporate Overview-Linear Motion Solutions Brochure (English)

- SOLUCIONES DE CONTROL DE MOVIMIENTO (Spanish, Corporate Overview-Motion Control Solutions Brochure)

- Unternehmensübersicht (German, Corporate Overview brochure)

- Brochure sur l'entreprise Tolomatic (French, Corporate Overview-Linear Motion Solutions Brochure)

- ServoWeld® SWA/SWB Integrated Servo Motor Actuators

- ServoWeld® Actuadores MODELOS SWA Y SWB (Spanish, ServoWeld® SWA/SWB Integrated Servo Motor Actuators)

- ServoWeld® SWA/SWB Integrierte Servomotorantriebe (SWA-B Actuator brochure, German)

- ServoWeld® 电动缸 SWA 和 SWB 型 (Chinese, ServoWeld® SWA/SWB Integrated Servo Motor Actuators)

- ServoWeld® Refurbishment and Remanufacturing Services

- Servicios de reacondicionamiento y refabricación de ServoWeld® (ServoWeld® Refurbishment and Remanufacturing Services-Spanish)

- ServoWeld® Aufarbeitungs- und Wiederaufarbeitungsservices (ServoWeld Refurbishment and Remanufacturing Services brochure, German)

- ServoWeld® 的翻新和再制造服务 (ServoWeld® Refurbishment and Remanufacturing Services-Chinese)

- ServoWeld with Integrated Force Sensor, brochure

- 带内置式力传感器的 ServoWeld (ServoWeld Force Sensor brochure ^CN)

- ServoWeld mit integriertem Kraftsensor (DE- ServoWeld w/Force Sensor brochure)

- Tolomatic Welding Solutions (English)

- Tolomatic SOLUCIONES DE SOLDADURA (Spanish, Tolomatic Welding Solutions)

- Tolomatic Lösungen für Widerstandsschweißen (Tolomatic Welding Solutions; German)

- Tolomatic 焊接解决方案 (Chinese, Welding Solutions)

- Automotive Applications Brochure

- Aplicaciounes de la Ind. Automotriz (Auto Appl SP)

- 汽车行业应用手册 Brochure (Chinese: Automotive Applications Brochure)

- All Electric Projection Welding Brochure

- Restore - ServoWeld Repair Program brochure

- Restore-ServoWeld Repair Program brochure^CN

- RESTORE WIEDERHERSTELLEN (Flyer DE)

- RESTORE (RESTAURAR); (flyer, ES)

Certifications

Guides

Terms & Conditions

Videos

White Papers

- Servo spot welding offers superior performance and lower lifetime costs for auto manufacturing

- A technical comparison: Performance of pneumatic cylinders and electric rod actuators

- Electric actuator technology comparison: Integrated and traditional designs

- How roller-screw and ball-screw actuators compare in high-force applications

- Actuadores eléctricos con vástago frente a cilindros hidráulicos: una comparación de los pros y los contras de cada tecnología (Spanish - White paper - Electric vs Hydraulic Actuators)

- Servomotorisches Punktschweißen bietet für die Autoproduktion herausragende Leistungswerte und senkt die Wartungskosten (GERMAN, Whitepaper, Servo spot welding offers superior performance and lower))

- Understanding Servo Linear Actuator Systems

Success Stories

Additional SWA Information

Tolomatic’s ServoWeld family of lighter weight integrated servo motor actuators for resistance spot welding (RSW) provide a cost-effective actuator design and best-in-class performance. SWA/B actuators provide users the lowest lifetime cost (lowest cost per spot weld) by providing the highest quality welds (best force repeatability) combined with the longest lasting actuators. ServoWeld SWA/B integrated servo spot welding actuators are highly efficient and the broad product family has many choices to optimize weight and performance.

SWA/SWB integrated servo motor actuators offer:

- 20+ million cycles for SWA models and 10+ million cycles for SWB

- Standard roller screw with highest dynamic load rating for more welds over competing roller screws, ball screws or pneumatic actuators

- Skewed motor windings designed for welding minimizes motor cogging for the best force repeatability

- Light-weight actuator design

- Forces to 4,000 lbf (17.8 kN)

- Optional water cooling

Ask an Engineer

Ask an Engineer