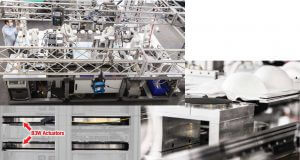

PPE (Mask) Manufacturing

Application Description:

Innovative mask workcell designed for high-volume mask making.

Challenge:

The pandemic hit New York City hardest in April 2020. As news unfolded and it became clear there was an immediate need for personal protective equipment (PPE), a local OEM knew they were uniquely positioned to help. The OEM chose to create a new generation mask-making machine based on the automated workcell concept to improve efficiency, quality and throughput. A primary goal was to maximize output with the smallest footprint and fewest workers as possible.

Tolomatic Solution:

Tolomatic’s B3W electric rodless actuators and GSA electric rod actuators were used on the automated workcell concept to improve efficiency, quality and throughput. The final mask workcell was designed with a small footprint to be fast and highly configurable, as well as easily adaptable to suit a variety of medical procedures.

Customer Benefit:

- Rodless actuator met space, accuracy, speed, configurability requirements

- Accurate control of positioning

- Easily modified to make different mask sizes, styles or materials and changes to strap material or length

MCHT-018-E

Ask an Engineer

Ask an Engineer