High-force linear motion: How to convert from hydraulic cylinders to electric actuators and why.

Hydraulic cylinders are traditionally the go-to technology for high-force linear motion, for good reasons. They deliver high force at a low cost per unit of force, they are rugged and simple to deploy. However, there’s a new technology to consider. Electric cylinders with high-force capacities are now available, and they are more flexible, precise and reliable than their hydraulic counterparts.

Following is a comparison of the performance and cost of each technology, as well as recommended methods for converting an application from hydraulic to electric actuation.

A comparison of hydraulic cylinders and electric actuators

Figure 1: Hydraulic Cylinder Figure 2: Electric rod cylinder

We will begin with a comparison of key parameters: force capabilities; motion control; system footprint; temperature tolerance; data collection; environmental concerns; and life cycle costs.

Force: Hydraulic cylinders have high operating pressures [124.1 to 206.8 bar (1800 to 3000 psi)]. Because Force = Pressure x Area, even a 76.2mm (3-inch cylinder) at 151.8 bar (2200 psi) can achieve 66.3 kN (15,000 lbf).

Roller screw-powered electric linear actuators can deliver forces of over 50,000 lbf (225.5 kN), which is sufficient for many applications.

With an electric actuator, force is generated instantaneously. The electrical current that passes through the servo motor produces torque that drives the roller screw and generates force immediately. A hydraulic actuator must wait for pressure to build until force is achieved, thereby slowing response. Or the actuator must store pressure (energy) constantly which creates inefficiency.

Motion control: A hydraulic actuator works best in uncomplicated, end-to-end applications.

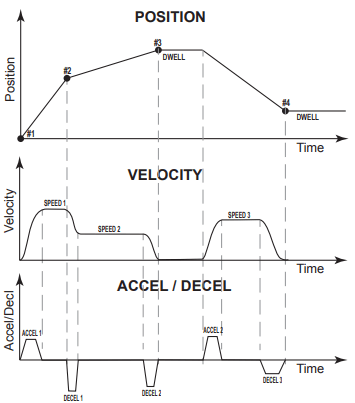

An electric actuator with servo drive/motor offers infinite control over position, velocity, acceleration/deceleration, output force and more. Adjustments can be made on the fly. Accuracy and repeatability are far better than hydraulics.

Figure 3: This chart shows different motion profile positions at different velocities with different accel/decel rates all under full and precise control.

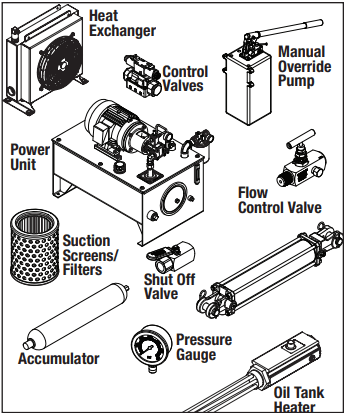

System footprint: A hydraulic cylinder offers a compact footprint at the work point, but the hydraulic power unit (HPU), which regulates oil pressure and flow, requires a lot of floor space. (See Figure 4)

Figure 4: Components of a hydraulic system take up a larger footprint than electric systems.

An electric actuator may have a little larger footprint at the work point but has a smaller overall system footprint, normally a fraction of that of a hydraulic cylinder plus HPU.

Temperature tolerance: Hydraulic cylinders can be temperature-sensitive. Cold results in sluggish and inconsistent hydraulic actuator performance. In higher temperatures, oil degrades and seals fail.

Electric actuators can be selected to run at a desired temperature for the given amount of work required. They can be specified with optional extreme temperature grease for fast response in the cold.

Data collection: Standard hydraulic actuation systems do not have data collection capabilities and require the addition of costly sensors or servo-hydraulics to attain the ability to gather process information.

Sensing capability is built into an electric actuator’s servo system through an encoder and current control. (See Figure 5)

Figure 5: Data Collection comparisons of electric and hydraulic systems.

Environmental risks: Hydraulic systems are prone to oil leaks that can create safety hazards, contaminate products and pollute the environment. Electric actuation is one of the cleanest linear motion technologies.

Life cycle costs: Hydraulic cylinders offer long life when maintained properly. However, maintenance (new seals, oil, and filters) can mean machine downtime. If an electric actuator is sized correctly for the application, no maintenance is required so there is no downtime.

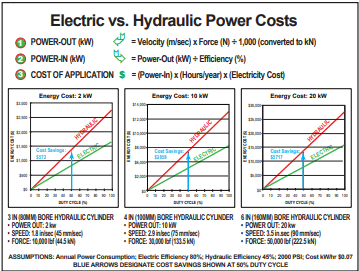

Hydraulic systems are only 40-55% efficient in converting electrical power to motion. Electric linear actuator systems typically operate at 75-80% efficiency. This difference in efficiency can result in major differences in the use of electric power. Electricity costs contribute significantly to the total cost of ownership of a device. (See Figure 6)

Figure 6: Comparison of power costs between electric and hydraulic systems.

How to convert from hydraulic to electric actuation

For many applications, electric actuation systems have a lower cost of ownership than hydraulic systems while delivering superior performance. Although the advantages for converting hydraulic to electric actuation are clear, the process of making the conversion presents several challenges. However, obtaining actual force and motion data and inputting the information into a manufacturer’s sizing software will yield an accurate recommendation for conversion.

Discovering actual force requirements

Over-sizing is common when specifying a hydraulic cylinder (see sidebar). Following are three methods for determining an application’s force requirements when they may have been overstated due to hydraulic cylinder over-sizing.

- Determine peak force Method #1. Meter down the pressure in the hydraulic system until the cylinder can barely do the work. This is a good approximation of the peak force. Use the actual pressure in the Force = Pressure x Area formula to get the actual force.

- Determine peak force Method #2. Measure the high pressure side and low pressure side (typically rod side) during the move with pressure gauges through the test ports of the valve. Remove the piston rod area from the low side and calculate an approximate peak force utilizing Force = High Side (Pressure x Area) + Low Side (Pressure x Area).

A warning for Method 1& 2: This process will only identify the peak force of the application rather than mapping the force over the full extend and retract cycle. (This is critical information for accurate electric actuator sizing.) Assuming peak force across the entire stroke will dramatically reduce the estimated life of the actuator. (Use the L10 life formula to calculate estimated life for electric roller screw actuators. See our Actuator Life)

- Install a load cell. Use a load cell to measure the force profile over the cylinder’s entire stroke. This will provide all the force information needed to accurately size an electric actuator, i.e., peak force and force at every point in the stroke. (Load cell readings will need to be stored in a PC or a data collection system to be analyzed.)

There can be difficulties with this approach. There may not be room to fit a load cell on the rod end of an existing installation. Or the application could require mechanical modifications to help with mounting the load cell between the actuator rod and the application load.

- Install a prototype servo motor electric actuator system. Use the current traces in the servo drive to back-calculate the torque/force profile for the electric actuator. This method can be used because current, torque, and force are all directly proportional. The more current through a motor, the more torque and subsequently the more force out of an actuator.

Calculate force using the equation:

Force = Force rating (current measured / Kt)

(Force rating and Kt are provided in the manufacturer’s specifications.)

The result is a close approximation of actuator force based on theoretical calculations. Actual results could vary by as much as 10%.

Mapping velocities

Every motion profile has parameters besides force that need to be considered when converting to electric actuation. Speed of moves is a critical parameter. Speed or velocity is the rate of change of distance over the rate of change in time. (Distance / Time)

We suggest recording the motion with a video and using the time stamp and distance traveled to approximate the speeds required for each move.

Getting electric actuator recommendations

When you have the actual force and motion data, you can input the information into a manufacturer’s sizing software for recommendations on products that meet your specifications. For example, Tolomatic sizing software provides a recommendation in just three steps.

- Define the parameters

- Describe motion profile

- Select product

Conclusion

Electric rod actuators can provide superior performance over hydraulic cylinders in many applications: higher accuracy and repeatability; programmable control of motion parameters; and better data collection and reporting capabilities. Electric actuators can also reduce total cost of ownership through efficient use of electricity and reduced downtime due to minimal required maintenance. Force capabilities of electric actuators have increased substantially; electric actuators with roller screws can deliver 50,000 lbf (225.5 kN) and higher.

The force requirements of applications are sometimes inflated by the common practice of over-sizing hydraulic cylinders by as much as three times. There are several ways to discover an application’s actual force requirements. This information, together with accurate speed and distance data, can be input into a manufacturer’s sizing software to yield recommended electric linear actuator models.

The danger of fluid power sizing

Because fluctuations in fluid pressure are common and the cost of fluid-powered cylinders is low, it is typical that these cylinders are sized at two or three times larger than what is required by the application. An engineer may consider this over-sizing to be insurance. However, the practice of over-sizing can obscure an application’s actual force requirements, making them appear quite high when in fact they are significantly lower than the cylinder’s rating.

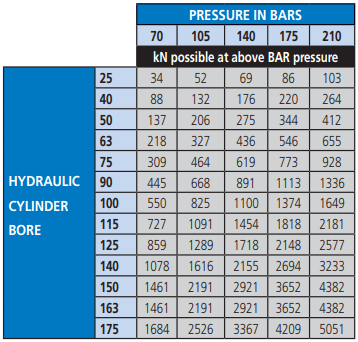

As a cylinder gets bigger, its force capabilities grow because Force = Pressure x Area. As the bore and oil pressure of a cylinder increase, the output force capability grows rapidly. (See Figure 7) The force output of an over-sized cylinder is much higher than what the application specifies.

Figure 7: Pressure and force capacities of hydraulic cylinder bores

This creates two challenges for conversion to electric actuation.

- Without thorough investigation, it may seem the application’s force requirement is much higher than what an electric linear actuator can deliver. It may look impossible to convert the application to electric.

- Electric actuators can have a higher purchase price than hydraulic cylinders. Oversizing can lead to unaffordable prices when applied to electric actuators.

Ask an Engineer

Ask an Engineer