Bullet Manufacturing

Product Family: Electric

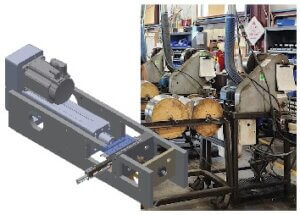

Product Used: RSA64 & RSX15 Electric Rod-Style Actuators

Product Type: Standard

Application Requirements:

Cycle rate: High cycle rate

Force: 5,000 & 7,500 lbf (22 & 33 kN)

Stroke: 4 in (102 mm)

Speed: 2 in/sec (51 mm/sec)

Application Description:

Bullet manufacturing, bullet pressing.

Challenge:

A bullet manufacturer wanted to replace a bullet press machine originally built in the 1960s. It required manual tooling adjustment and it was inconsistent. Designing a new machine to press bullets involved several considerations, including efficiency, safety, and compliance with relevant regulations. Additionally, the manufacturer wanted the lower operating cost, greater accuracy, repeatability and faster product changeover available with electric actuators.

Tolomatic Solution:

Using Tolomatic’s online sizing tool it was determined that the RSA64 & RSX15 would provide the high force required in a relatively small size. The actuators replaced the flywheel from the old machine. The YMH (Your Motor Here) program mated the actuators to the customer supplied motors. Once the new bullet press machine design has been proven for 6 months they intend to build two more and hire more people to multiply production.

Customer Benefit:

- Simple tool change and more controllability

- Higher production rate (25 -35% increase)

- Less scrap, high accuracy & repeatability, feedback = more perfect bullets

- Increased safety via current and torque monitoring/limiting

- Energy and cost savings, lower maintenence requirements

DEF-013-E

Ask an Engineer

Ask an Engineer