Actuator Life: How to estimate for ball and roller screw actuators

Introduction

Estimating how long a piece of equipment will last in an application is critical information in the specification process. This step-by-step guide examines how to estimate the life of an electric actuator, utilizing ball or roller screw technology, in applications that require constant or varying (changing) loads. In addition, you will learn how to calculate life in units of time (days, years, etc.) and how to compare the expected life of two different solutions.

Load is just one factor affecting the service life of an actuator. Factors that can negatively affect life or lead to premature failure include incorrect mounting/alignment, lubrication starvation, temperature and other environmental extremes. Consider each of these factors to ensure a long service life and maintenance-free operation for your application.

NOTE: The calculations shown in this guide are theoretical life estimates and not a guarantee of actual actuator life

Definitions

Dynamic Load Rating (DLR)

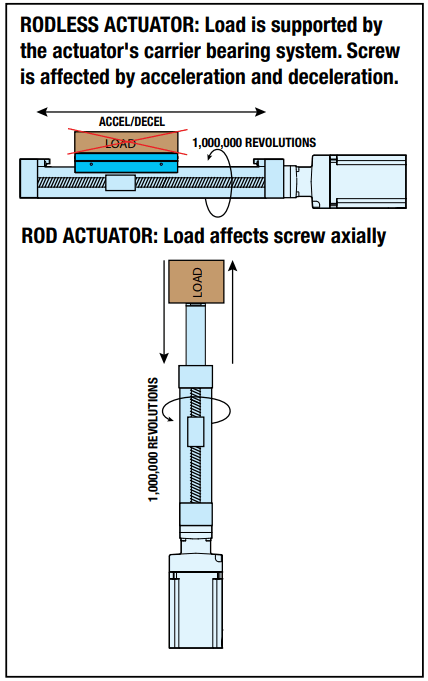

DLR is a bearing term that represents an applicable constant load (in direction and magnitude) where a ball bearing device will achieve 1,000,000 revolutions (rotations) of rated life.

- Also known as symbol C.

- Provided by manufacturers for ball & roller screw combinations.

- Magnitude of the dynamic load rating (DLR) typically depends on the screw diameter, screw lead and number of recirculating rolling elements (balls or rollers) inside the nut that simultaneously carry the load.

NOTE: Screw manufacturers typically publish theoretical DLR numbers for their screws.

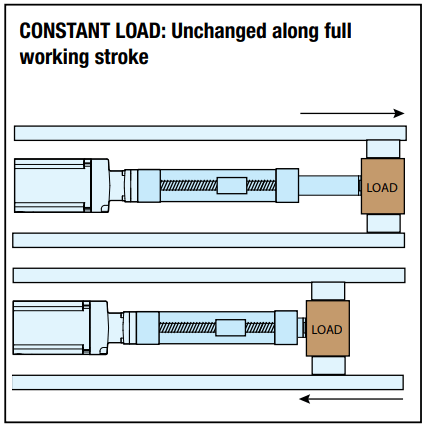

Constant Load

A constant load is a load that remains unchanged along the full working cycle.

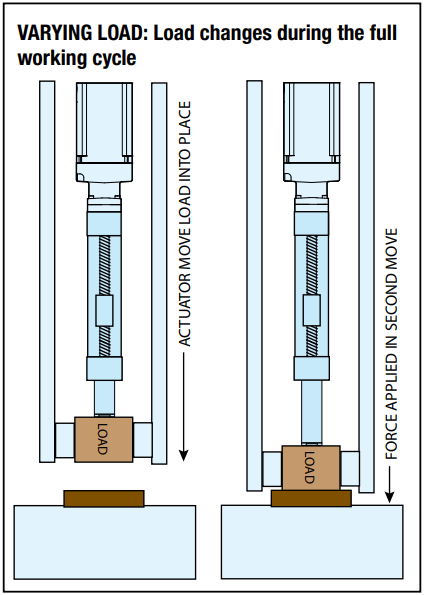

Varying Load and Equivalent Dynamic

Load In the case of a varying load (a load that changes during the working cycle), it is necessary to calculate the equivalent dynamic load or Pe.

Equivalent Dynamic Load or Pe is a dynamic load acting on the screw, which if applied constantly would have the same effect on the screw life as the combined actual loads.

In the case of constant load: equivalent load = actual load

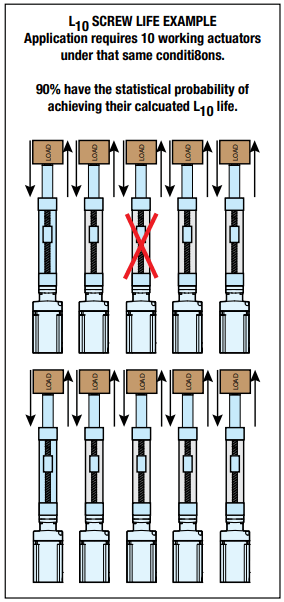

“L10” Life

L10 is a calculation of life at which 10% of the bearings in that application can be expected to have failed due to classical fatigue failure. (Or alternatively, the life at which 90% will still be operating). L10 life for a group of identical screw actuators operating under the same conditions, is a life of such magnitude that 90% of these actuators have the statistical probability to achieve.

- Does not include any other mode of failure like lubrication starvation, incorrect mounting, etc.

- L10 life calculation provides a theoretical life estimate based on a collection of statistics. This is not a guarantee of performance but a guide for expected life.

- Outside the USA, it may be referred to as “B10” life

How to estimate life (L10) with a constant load

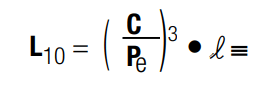

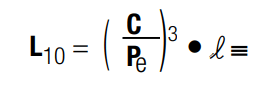

To estimate life with a constant load the underlying formula that defines this value is:

L10 Travel life in millions of units (in or mm), where:

C = Dynamic load rating (lbf) or (N)

Pe = Equivalent load (lbf) or (N)

- If application load is constant across all movements, then: the equivalent load = actual load

- If application load is varying across movements, then: an equivalent load must be calculated (see next page)

NOTE: Use same units (lbf or N or kN) as DLR so units cancel each other

l = Screw lead (in/rev) or (mm/rev) NOTE: Use desired linear units (in or mm).

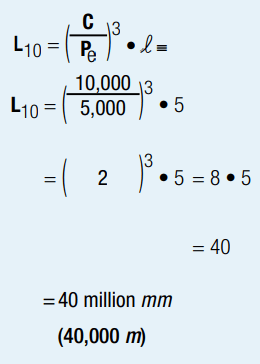

EXAMPLE

Estimating Life (L10) with a constant Load

To calculate travel life:

C = 10,000 lbf

Pe = 5,000 lbf

l = 5 mm

The underlying formula that defines this value is:

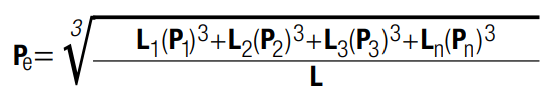

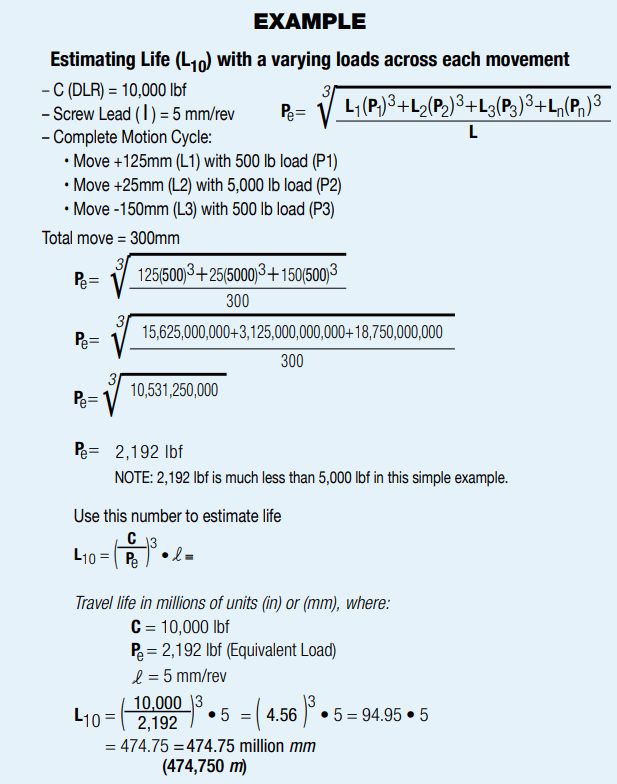

How to estimate life (L10) with a varying load

As explained in the definitions on page 5, when a load varies during the working cycle is it necessary to calculate the equivalent dynamic load (Pe). Pe is defined here again as a dynamic load acting on the screw axially and centrally, which if applied constantly would have the same effect on the actual screw life as the combined actual loads.

Use the “Equivalent Load” calculation below, when the load is not constant throughout the entire stroke. In cases where there is only minor variation in loading, use greatest load for life calculations.

Where:

Pe = Equivalent load (lbs) or (N)

Pn = Each increment at different load (lbs) or (N)

L = Total distance traveled per cycle (extend + retract stroke) (L = L1 + L2 + L3 + Ln)

Ln = Each increment of stroke (in) or (mm) at different load

Then use the calculated Pe in the life calculation shown previously.

Remember…

C = Dynamic load rating (in) or (mm)

Pe = Equivalent load (lbf) or (N)

l = Screw lead (in/rev) or (mm/rev)

How to estimate life (L10) with a varying load

NOTE: Over 10 times the travel life over simple application. When varying load is ignored and simplified to 5,000 lbf (to be conservative or to do a quick calculation) the rounding error can be magnitude of the calculated difference can be large and misguide selection of actuators. Be sure to fully understand if the application is constant load or varying load.

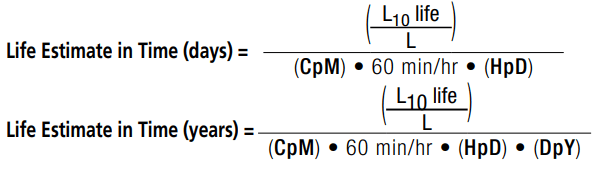

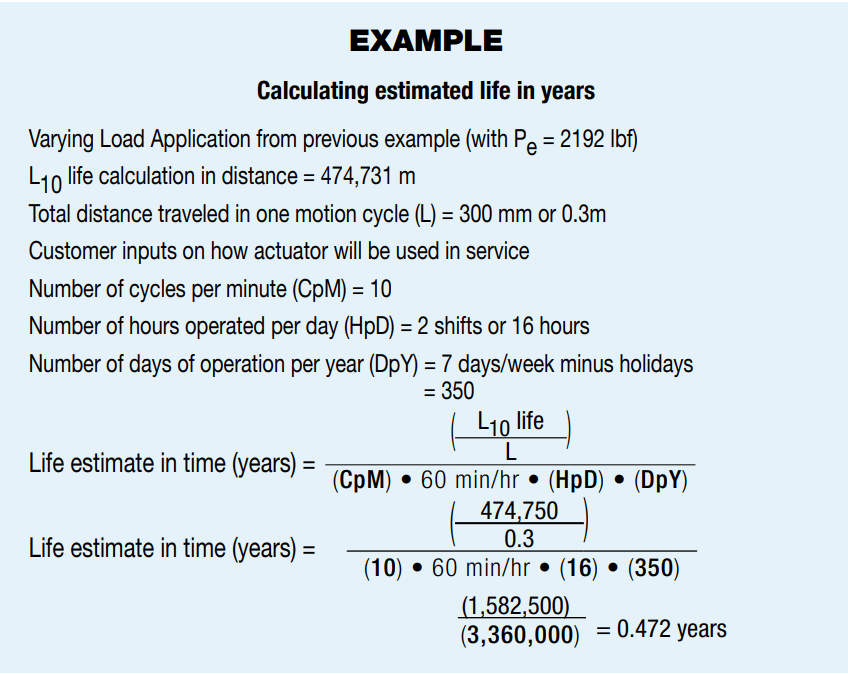

How to calculate estimated life in time (days, years)

What do you need?

- L10 life calculation in distance

- L Total distance traveled per cycle (extend + retract stroke)

- Number of cycles per minute (CpM)

- Number of hours operated per day (HpD)

- Number of days of operation per year (DpY)

How to compare life between two actuators

Use the formula below to compare actuator products.

NOTE: Use higher DLR as DLR A. This formula can be used to compare: ball vs. roller, size 1 vs. size 2, or manufacturer A vs. manufacturer B.

Summary

When determining the life of an actuator, inside a machine application, it is important to evaluate the effects of loading on the screw. Calculating for constant loads requires a different formula than calculating for varying loads. Besides load, other factors affect how the screw performs inside the actuator, including manufacturing methods, actuator design, lubrication, velocity, temperature, wear, corrosion, contamination and other dynamic elements such as misalignment and vibrations.

The calculations contained in this guide will give you a general estimation of actuator life based on statistical data. To ensure long service life of your application, consider these other factors, in addition to load, in your specification analysis.

Ask an Engineer

Ask an Engineer