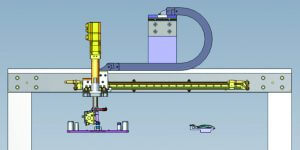

Transfer Station

Product Family: Electric

Product Used: ERD Electric Cylinder; MXP Profiled Rail Pneumatic Actuator

Product Type: Standard

Application Requirements:

Vertical (z-axis) actuator: 4-inch stroke; Speed: 1.25”/.25 sec moves at Pick-and-Place; Load: 20 lbs (Tooling and Product)

Horizontal (Y-axis) actuator: 25-inch stroke; Speed 25”/3 sec moves; Load: 35 lbs (Z-axis actuator, Tooling and Product)

Application Description:

Indexing conveyor transfer station

Challenge:

A transfer station, was using pneumatic power to transfer parts but manual labor to pick and place the products from one conveyor line to another during a 24/7 work week. Initial concerns from management were quality and accuracy during station transfer. There were also repeated instances where packaging was not consistent with cycle counts. To achieve cycle rate requirements, speed, accuracy and repeatability, a fully automated solution was required.

Tolomatic Solution:

On the z-axis, an ERD15 electric cylinder was selected as a cost-effective way to pick and place parts to the conveyor lines along with providing the necessary repeatability. On the Y-axis, an MXP pneumatic actuator with a profiled rail replaced the old pneumatic actuator to transfer the parts. It was selected for its load carrying capacity and easy retrofitting into the existing station design.

Customer Benefit:

- Achieved quick, accurate, repeatable process

- Eliminated manual labor

- Improved consistency of package contents

- Compatibility with desired motor and drive lines

CONV-011-E

Kontakt zu einem Ingenieur

Kontakt zu einem Ingenieur