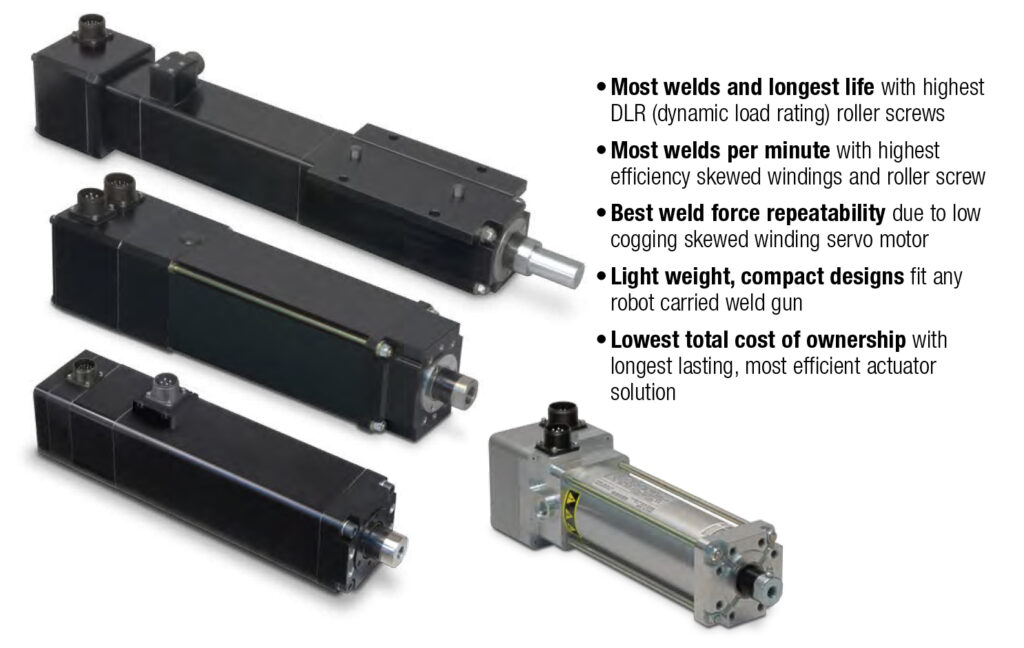

Best-in-class Integrated Servo Actuator

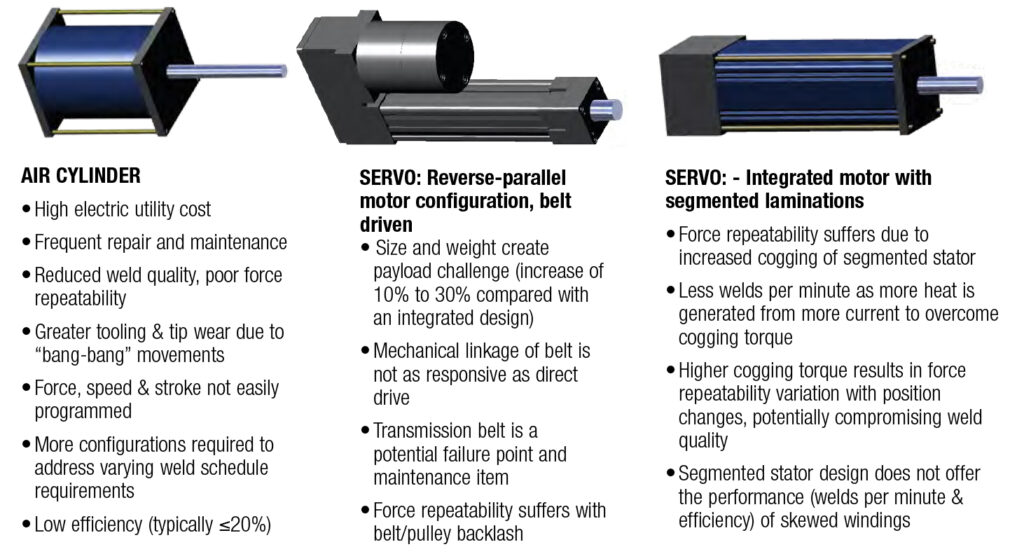

Competing Technologies

Air cylinders, and competing servo actuator designs can’t compare to ServoWeld®

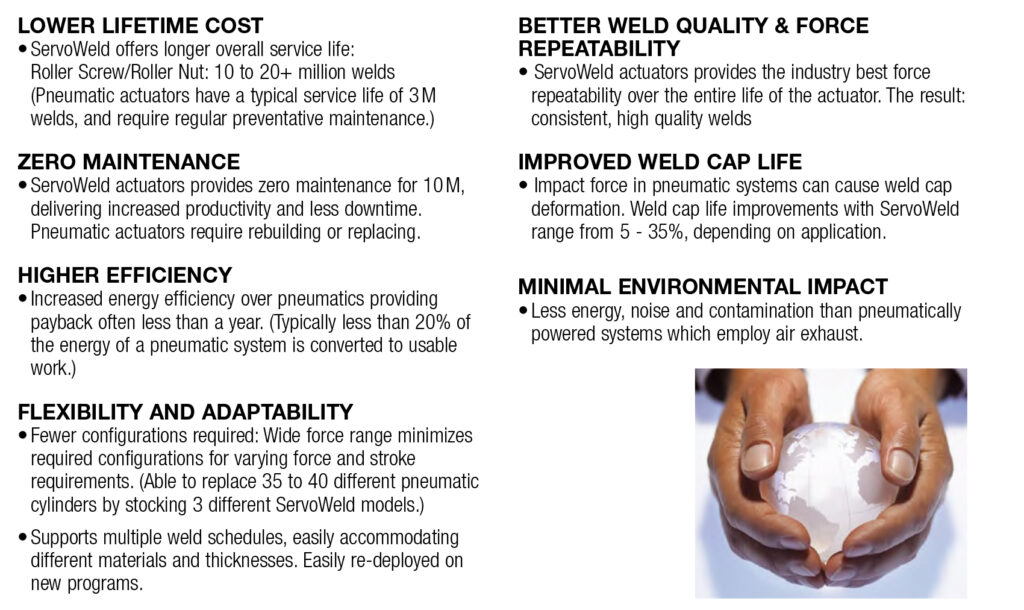

ServoWeld Advantages Over Pneumatic

For many years the RSW industry has been abandoning pneumatic actuators for electric actuators.

Accuracy, speed, efficiency, force repeatability and total cost of ownership have all made ServoWeld the preferred choice when converting to all electric manufacturing.

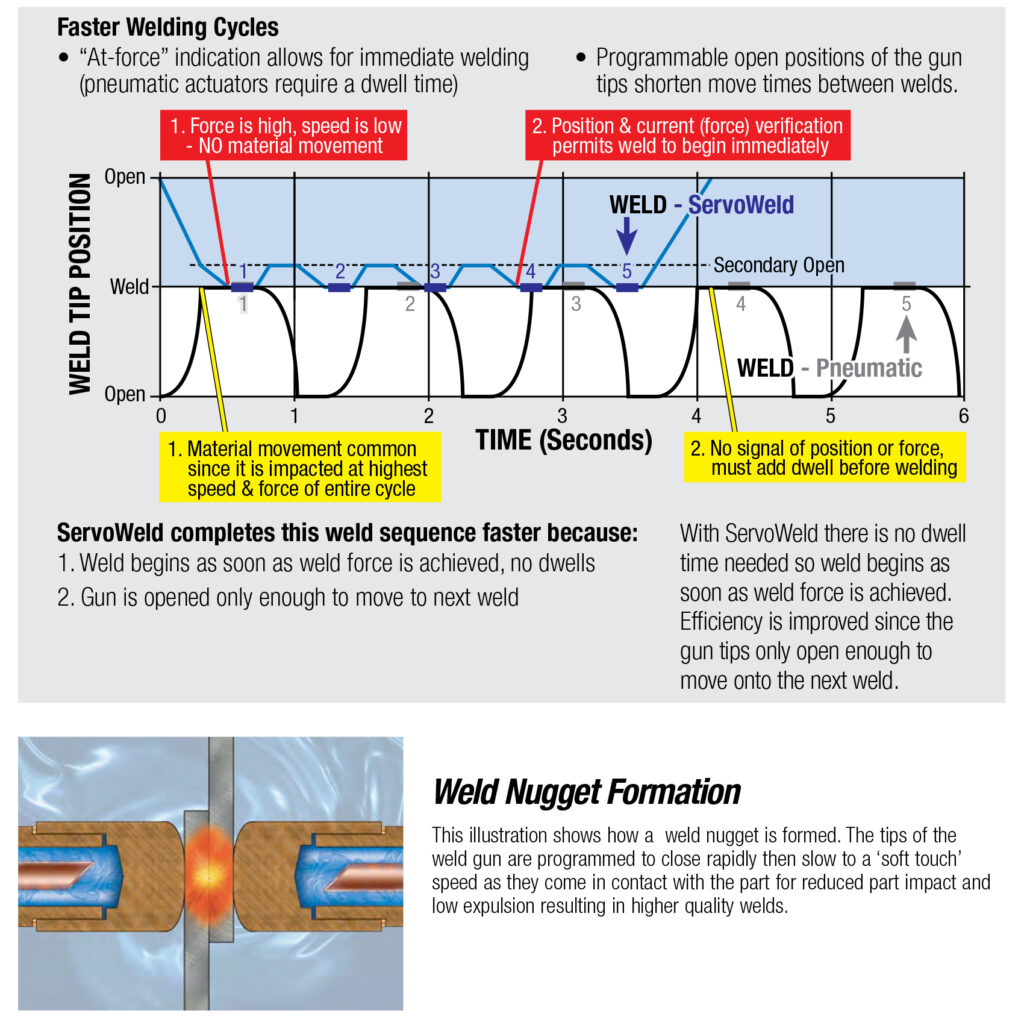

Higher Quality Welds & Manufacturing Flexiblity

Tolomatic’s ServoWeld® actuators offer RSW users a higher level of performance when compared to pneumatic actuators.

Higher Quality Welds

- Force repeatability for consistent welds

- “Soft-touch” position and speed control for high repeatability and eliminates high-impact effects on part and weld gun for reduced wear

- Position and force can be recorded for each weld

- Position and data form feedback device an provide data for weld cap wear and lost cap detection capability

Complete Manufacturing Flexiblity

- Using weld or robot controls, the ServoWeld actuator can be easily programmed to accommodate model or tool changes

- Existing 6-axis robots can be retrofitted with multiple ServoWeld actuators to achieve all the advantages that servo welding offers.

- Operation can be coordinated with robot axis movement

- Using weld or robot controls, the ServoWeld actuator can be easily programmed to accommodate model or tool changes

- Existing 6-axis robots can be retrofitted with multiple ServoWeld actuators to achieve all the advantages that servo welding offers.

- Operation can be coordinated with robot axis movement

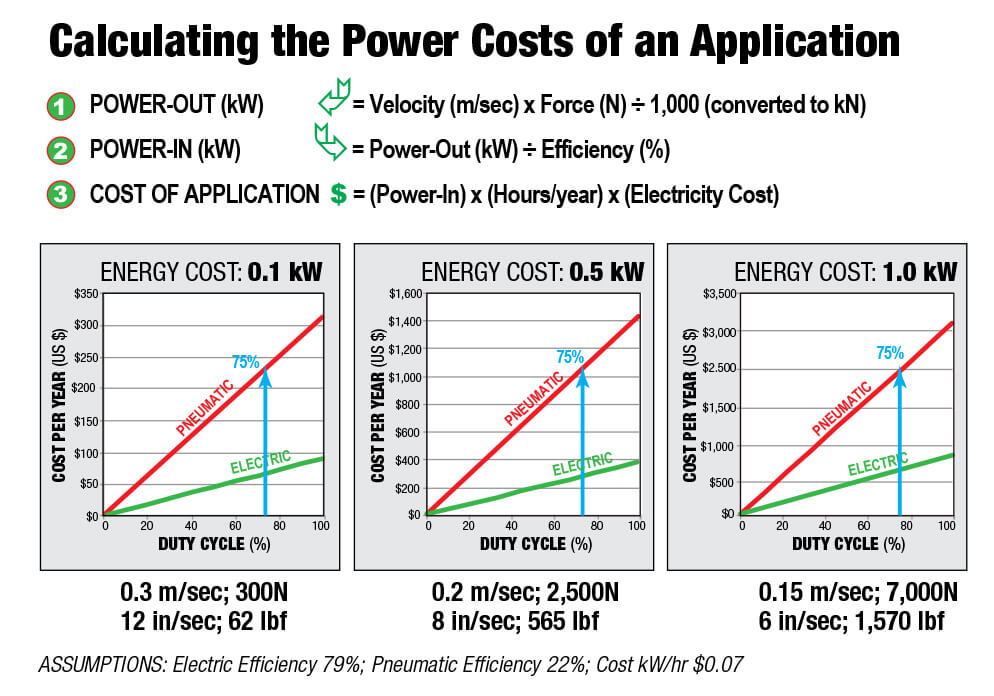

Estimating Power Costs

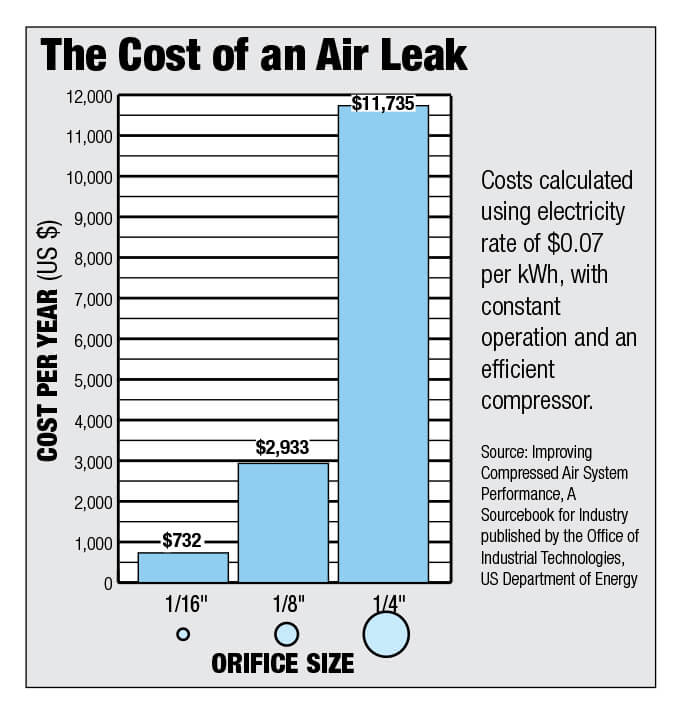

Cost of an Air Leak

Ask an Engineer

Ask an Engineer