Roller screw technology for electric actuators

By Ryan Klemetson on August 25, 2020

In the world of linear motion every application is different. For high duty cycle, larger force applications you will typically have two choices: ball screws or roller screws. Each technology is unique and has its place. Your best guide for which one to use is the application itself. Carefully evaluating the application’s specifications will ensure you optimize performance and cost.

In the world of linear motion every application is different. For high duty cycle, larger force applications you will typically have two choices: ball screws or roller screws. Each technology is unique and has its place. Your best guide for which one to use is the application itself. Carefully evaluating the application’s specifications will ensure you optimize performance and cost.

Typically, roller screws are used with high force, heavy duty linear actuators. The unique design of a roller screw offers longer life and higher thrust in a smaller package compared to ball screw actuators, increasing a machine designer’s ability to create compact machine concepts.

Roller screw in motion: See the video.

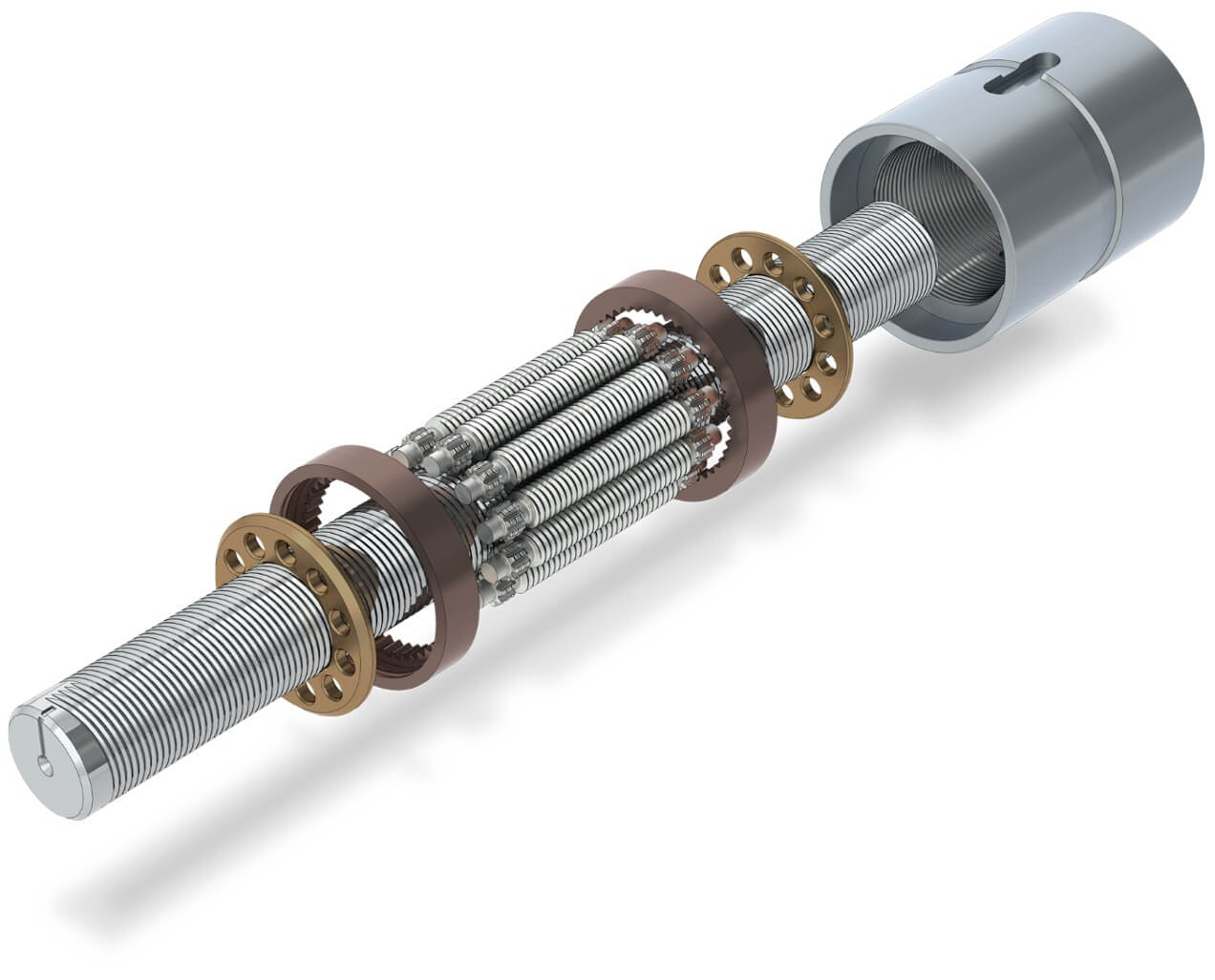

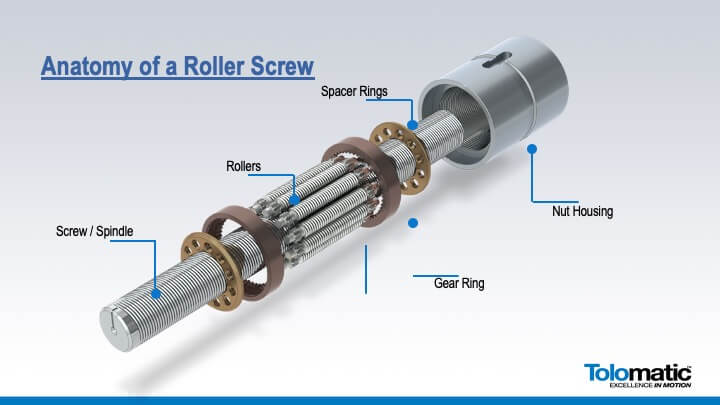

Anatomy of a roller screw

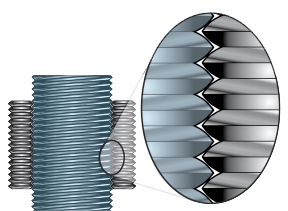

In an electric rod actuator, the screw/nut combination converts the rotary motion of the motor to linear motion. Roller screws (also called planetary roller screws) have precision-ground threads that match multiple precision-ground rollers in the nut. These rolling elements transmit force very efficiently. Similar to a planetary gear box, the screw/spindle is the sun gear; the rollers are the planets. Gear rings and spacers hold the rollers inside the nut. While the rollers are orbiting the screw, a small amount of sliding occurs, which is one of the stark differences from a ball screw. By constraining either the screw or the nut from rotating (typically done with the screw), this allows the other rotating element to move across the stationary element; thus creating linear motion in the same way that motion from a ball or acme screw is produced.

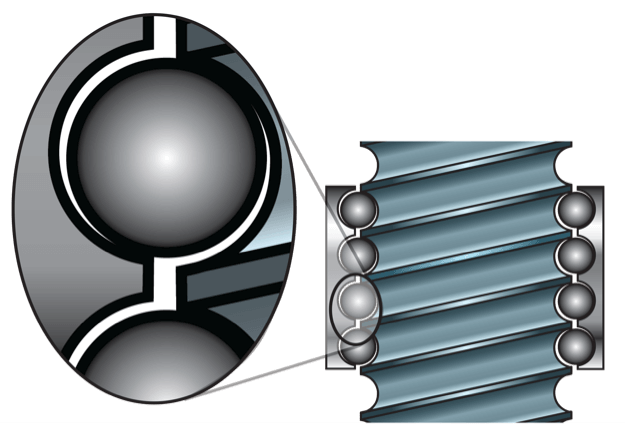

Ball screws get their name from the use of re-circulating ball bearings that recirculate within raceways in the screw threads and corresponding threads in the nut. The ball bearings transmit force and relative motion efficiently as they roll through one or more circuits in the nut.

For complete details of roller screws, visit our educational page

Screw terminology basics

- Lead —The distance the nut advances with each revolution of the screw (inch or millimeter per rev)

- Pitch — The axial distance between threads

- Backlash — The distance between screw and nut engagement when reversing direction or force.

- Lead accuracy — Possible variation in travel over a standard length of screw (inch/foot)

- Backdriving — The ability of an external force or load to cause rotation of the screw through the nut.

- Load rating:

- Static—Maximum load that may be applied before damage occurs

- Dynamic — A value used in the life calculation of a system. Used in L10 life estimation

Tolomatic’s online electric actuator sizing software guides engineers through specifying their application including force, speed, dwells, and other factors to help you make the correct choice.

Roller screw and ball screw comparison

Roller screw components provide more points of contact allowing for higher force capability and longer life in the same package size compared to ball screws. However, this increased contact area and the aforementioned sliding friction creates more heat with the same amount of work. Roller screws are good choices for repeated stress applications in same area of actuator stroke, such as pressing, inserting and riveting.

Ball screws, because they have fewer contact points, are more efficient in heat management than roller screws which allows them to operate cooler in high duty cycle and high speed applications. Ball screw actuators are ideal for applications that require high duty cycles, moderately high thrust and moderate speeds.

In both roller and ball screw assemblies, heat management is a major factor in how well lubricants perform ultimately affecting if actuator/screw choice will last as long as expected. If left unchecked without proper addition of lubrication, it will begin to break down. Greases lose their ability to protect the metallic components. As the temperature rises and nears the maximum rating of the grease, the effectiveness of the lubrication decreases. Because of this, maintaining the lowest possible average temperature of the screw/nut will help with determining how much lubrication is needed. Tolomatic’s sizing software will not let roller screw actuators exceed a threshold for temperature to safely guarantee the actuator will work in an application. When applications exceed this threshold, that is not an indicator that the screw will not work but should be used as an indication that continued maintenance of the screw through the addition of grease will be essential to achieving the maximum service life of the screw.

For most applications that require high force, repetitive cycles and long expected life, Tolomatic will most likely recommend a roller screw linear actuator. However, if the force is lower and high continuous speeds are present in the application, a ball screw actuator may be the better solution.

Tolomatic roller screws are manufactured using state-of-the-art equipment to ensure strict tolerances and the highest quality standards are upheld so that each roller screw provides top-tier performance.

Find out which technology is best for your application. Contact a Tolomatic engineer. Or check out our sizing software.

Download our reference materials:

Ask an Engineer

Ask an Engineer