Selection tips: rodless electromechanical & electric rod actuators

By Tolomatic on January 9, 2018

When you specify a linear actuator, some basic decisions come first. Like electric or fluid-powered? Like do you need the push/pull of an electric rod actuator or the load-carrying action of a rodless electromechanical actuator?

When you specify a linear actuator, some basic decisions come first. Like electric or fluid-powered? Like do you need the push/pull of an electric rod actuator or the load-carrying action of a rodless electromechanical actuator?

We’ve compiled tips for selecting these actuator types. Here’s an opportunity to increase your knowledge of electric linear motion with two white papers: How to specify electric rod-style actuators for optimal performance, reliability and efficiency and Specifying electric rodless actuators: Ten tips for maximizing actuator life and system performance. Download them here.

Selection tips for electric linear actuators

Rod-style or rodless, here are tips for specifying the right electric motion solution for the task.

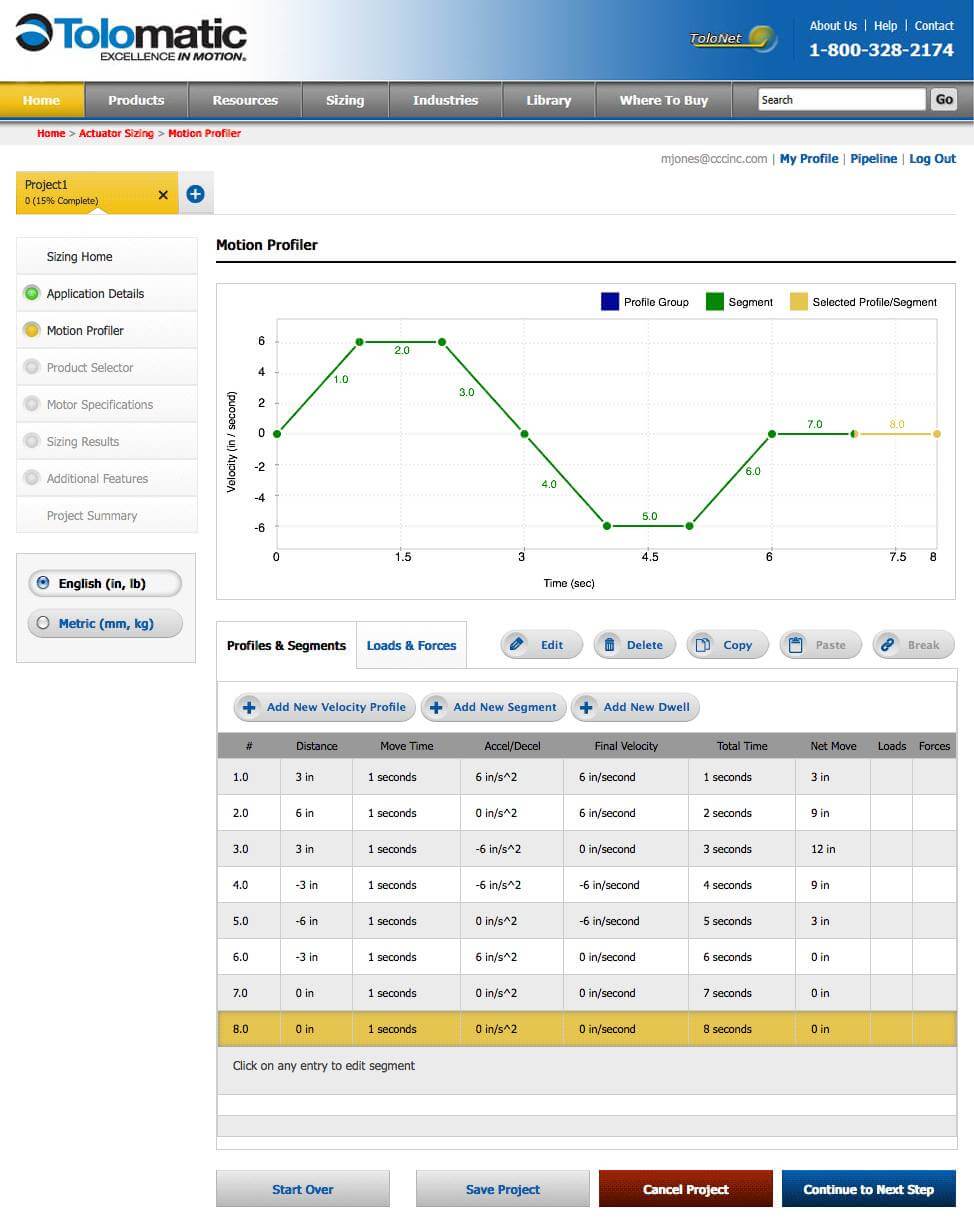

- Calculate size for electric, not fluid power Don’t fall into the common fluid power practice of oversizing. Fluid-pow

ered actuators can be low cost, so a bigger cylinder won’t blow the budget. In comparison, electric actuators have higher purchase prices, so oversizing can be costly. Use sizing software offered by manufacturers to get the right size linear actuator for your application.

ered actuators can be low cost, so a bigger cylinder won’t blow the budget. In comparison, electric actuators have higher purchase prices, so oversizing can be costly. Use sizing software offered by manufacturers to get the right size linear actuator for your application. - Calculate loads precisely If you know the weight and size of the load, how far it needs to travel and how fast it needs to move, you can accurately specify actuator components, like screws, bearings and motors. Accurately-specified components mean longer service life for the linear actuator.

- Factor in the duty cycle Duty cycle for a linear actuator is the ratio of operating time to resting time. It’s expressed as a percentage. Knowing the duty cycle means you can specify an actuator that will last.

- Set critical speed limits Actuator lead screws have critical speed limits. If the screw has to operate at or beyond its limit, it will oscillate, causing noise and vibration. Long-term effects could be premature wear and even catastrophic failure.

- Factor in the environment Moisture, dust and corrosive agents can cause problems for linear actuators. If a linear actuator is in a washdown environment, there are special issues to consider.

- Look beyond footprint when specifying a drive system Reverse parallel motor mounting has the appeal of saving space, but the fact that power is transmitted through belts or gears means these configurations are less power and efficiency. Sometimes only an inline motor configuration delivers the speed and thrust required.

- Match actuator capabilities to life expectations An electric linear actuator will fail if its drive or carrier bearing system is over-stressed by load and speed. For long service life, specify an actuator that’s suited to the task.

Special tips fo r electric rod actuators

r electric rod actuators

Because an electric rod actuator pushes or pulls its load, there are two special considerations to keep in mind when specifying this type of actuator.

-

Avoid side loading Electric rod actuators do not support the load, so the load’s weight can deflect the rod and cause wear on seals and bearings as well as accuracy problems.

- Keep total envelope size in mind Since the rod extends beyond the actuator body, the total footprint will be the actuator length plus the stroke length.

Special tips for rodless electromechanical actuators

A rodless electromechanical actuator carries its load and is subject to different stresses than its rod-style counterparts. Here are two tips for specifying rodless actuators.

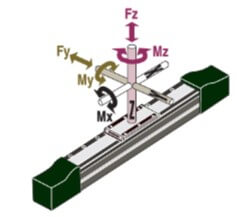

- Calculate all moments (torques) Since rodless electromechanical linear actuators carry loads, the load-carrying platform will be stressed. You can only specify the right actuator for an application if you’ve calculated carrier roll, yaw and pitch.

- Mounting makes a difference Mounting is always critical but especially for a long-stroke rodless linear actuator. You’ll need enough support points to ensure rigidity. Also, you’ll need a mounting surface that’s straight and flat, plus room for the actuator/motor combination.

Tolomatic has broad offerings of both rod-style and rodless actuators, so we can help you find the best electric linear motion solution for your application.

Learn more

For tips on selecting electric linear actuators, down our white papers: How to specify electric rod-style actuators for optimal performance, reliability and efficiency and Specifying electric rodless actuators: Ten tips for maximizing actuator life and system performance.

Interested in electric linear motion? Join the discussion at our LinkedIn group.

Ask an Engineer

Ask an Engineer