Mechatronics, electric linear actuators and control system design

By Gary Rosengren on March 3, 2015

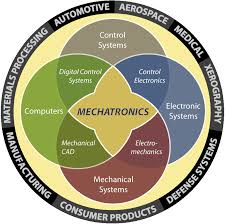

If you’ve been around engineering, you’ve probably heard the term “mechatronics” used to refer to a design process that blends mechanical engineering, electrical engineering, telecommunications engineering, control engineering, and computer engineering. Mechatronics is a multidisciplinary approach that rejects splitting engineering into rigidly separate fields. Originally, mechatronics just included mechanics and electronics; however, as technical systems have become more complex the word has been broadened to include more technical areas.

If you’ve been around engineering, you’ve probably heard the term “mechatronics” used to refer to a design process that blends mechanical engineering, electrical engineering, telecommunications engineering, control engineering, and computer engineering. Mechatronics is a multidisciplinary approach that rejects splitting engineering into rigidly separate fields. Originally, mechatronics just included mechanics and electronics; however, as technical systems have become more complex the word has been broadened to include more technical areas.

We design our electric linear actuators to be part of "mechatronic systems" — computer-controlled mechanical systems, systems that include both an electronic computer and electromechanical components. Most modern industrial control systems that use our linear actuators fit this description.

A holistic approach to design

Today’s automation solutions need to be faster, smarter and communicate better, so machine design engineers must take a broad view. When specifying electric linear actuators for an integrated control system that takes mechatronics principles to heart, consider these factors:

1. Application requirements for

- Service life

- Thrust

- Velocity

- Stroke length and overall length

- Accuracy and repeatability

- Life cycle cost

2. Environmental factors

- Temperature extremes

- Moisture

- Dust and abrasives

- Caustic solutions

3. Communication issues

- System protocols

- Sources of electrical noise

- Data to be communicated

- Timing (when; how often)

4. Programmability

- Actions to be programmed

- Degree of control needed

Once the application’s parameters are thoroughly documented, we suggest you work closely with a motion control supplier. After all, there are many variables to consider when specifying an electric linear actuator: rod or rodless; belt or screw drive; acme, ball, or roller screw; stepper or servo motor; inline or reverse parallel motor configuration; type of controller/driver. An electric linear actuator supplier’s expertise will help you identify the best product configuration for your system.

Ask an Engineer

Ask an Engineer