What you need to know about electric linear actuators

By Tolomatic on April 7, 2015

Electric or pneumatic? That is the question. Or at least it’s a crucial question that control systems and machine design engineers ask early in the process of specifying a linear actuator. A pneumatic cylinder may be the best solution — easy-to-understand, lower cost — but then again an electric linear actuator can offer distinct advantages. It really depends on the application.

Electric or pneumatic? That is the question. Or at least it’s a crucial question that control systems and machine design engineers ask early in the process of specifying a linear actuator. A pneumatic cylinder may be the best solution — easy-to-understand, lower cost — but then again an electric linear actuator can offer distinct advantages. It really depends on the application.

Here is an explanation of what you should know about electric linear actuators:

Advantages of electric linear actuators

- Able to handle complex motion profiles As motion control systems have become more complex and sophisticated, control engineers and machine designers have turned to electric actuators because they offer greater control and accuracy. Plus, electric linear actuators are fully programmable, which adds application flexibility. Programmability is often the most important point in favor of electric actuators, whether rod or rodless. These actuators can be programmed for multiple starts and stops, as well as for different speeds during various segments of their travel.

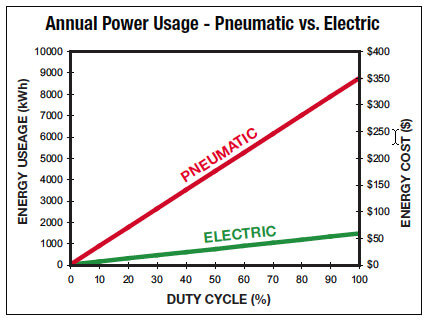

- High efficiency and lower energy use Electric systems operate at 70-80% total system efficiency. That makes electric actuators an

environmentally friendly choice because they use less power, and they’re a solution that can keep operating costs down. (Compressed air systems can be as low as10-15% efficient and use more energy.)

environmentally friendly choice because they use less power, and they’re a solution that can keep operating costs down. (Compressed air systems can be as low as10-15% efficient and use more energy.) - Able to adapt to changing needs The electric actuator’s programming can be changed. So if parameters change—like part geometry, speeds, or start/stop points—the actuator can be adjusted quickly to meet these new specifications. There’s minimal downtime and loss of productivity.

- Lower operating cost If you look at a linear actuator’s life cycle cost in total, the combination of high efficiency, low energy use and minimal need for maintenance mean an electric actuator can cost far less than a pneumatic cylinder even though the initial purchase price (acquisition cost) for the electric actuator may be higher.

Limitations of electric linear actuators

- Complexity Traditional electric actuator systems involve a number of components – the actuator itself, motor, controller/driver, and cabling –

which must be integrated. Selecting components, integrating them, and programming the entire system require sophisticated control knowledge and more set-up time and effort. There are integrated electric linear actuators that can simplify selection and integration. Also, some actuator suppliers can provide application assistance.

which must be integrated. Selecting components, integrating them, and programming the entire system require sophisticated control knowledge and more set-up time and effort. There are integrated electric linear actuators that can simplify selection and integration. Also, some actuator suppliers can provide application assistance. - Purchase price As noted above, the purchase price (acquisition cost) of an electric actuator system may be higher than that of a pneumatic cylinder. If purchase price is the primary factor in a buying decision, an electric actuator will be at a disadvantage. But over the life of the control system, an electric linear actuator will help reduce operating costs and improve efficiency.

Resources

For more information, see our white paper on comparing total cost of ownership of pneumatic and electric linear actuators

Ask an Engineer

Ask an Engineer